A relatively new material - laminate - occupies an increasingly prominent place in the building materials market as one of the most inexpensive materials that is easy to work with. At the same time, it gives an excellent result in visual perception of the floor covering, ease of maintenance and durability. But such a result is possible only with a high-quality finished coating and a correctly selected substrate for the laminate.

Functionality of the substrate for the laminate

For the successful use of this type of coating, there are a number of requirements that must be adhered to. They relate, first of all, to the formation of the floor “pie”, a multilayer device that compensates for the weaknesses of the finish coating and ensures the full performance of the floor in its entirety. To do this, in front of his flooring, a substrate is formed under the laminate, on which such tasks are assigned:

- steam protection, the purpose of which is to protect the floor cake from moisture coming from below,

- insulation function - minimization of heat loss from the floor screed, which is especially important when the floor slabs of the first floor are located above the basement intended for storing products with a special thermal regime,

- sound insulation - relevant for second and higher floors,

- alignment of defects of the rough screed, which is especially important when using a laminate as the final floor covering.

What is the best substrate for a laminate to choose for our readers. To understand the problem, find out what a laminate is.

The basis for the manufacture of such a board is a wood - fiber board of increased strength. The surface is covered with a layer of melamine or acrylate resin, which is a protective layer. A decorative layer of paper under a transparent coating can imitate any surface from wood to stone. The bottom layer is waterproof due to the impregnation of paper, protects the board from moisture. A number of manufacturers mating elements are coated with a layer of wax.

Non woven fiber backing

This is perhaps the best choice as a substrate for a laminate. Fiber floor substrates differ from all their competitors not only in terms of price / quality, but also in their best physical performance.

The Trioteks company is engaged in the production of these substrates, and has already established itself as a reliable supplier of quality materials.

The advantages of fiber substrates:

- Excellent moisture insulation - the substrate is covered with a protective film that does not allow it to get wet,

- Sound insulation - due to its structure, the material almost completely absorbs sound,

- Thermal insulation - in terms of its thermal insulation properties, non-woven fiber can compete with cork coatings,

- Perfectly smooth out small bumps - the main purpose of the substrates. And with this substrate from the company "Trioteks" cope best.

Among other things, fiber substrates are not susceptible to decay and "sagging" over time.

Installation is one of the easiest among competitors. Unlike other fragile materials (cork, needles, polystyrene foam), it is enough to roll the material on the floor and cut it in the right places.

The pad from the Trioteks company is suitable for any purpose - for leveling the floor by laying the laminate, for its sound insulation and insulation.

Cork materials

Crushed natural material cork as a substrate is formed into rolls on a fabric basis, the thickness of the material is 2 - 10 mm. Due to its physical properties, it is popular because of its ability to smooth out point irregularities, leveling their effect on the laminate.

Cork backing also works well when laying on a wooden floor. In this case, the surface preparation consists in removing old paint using scrapers or a special composition designed for this purpose. The field of this must be secured by creaky floorboards with additional screws or nails to the floor logs. Chips and cracks must be repaired with putty of a special composition for wood.

When laying the substrate, the usual technology is used for such cases. Runs of sheet material are laid on the floor, while joints are allowed, both in width and in length, which must be glued together with construction tape. Attention! When laying the substrate, local swelling and swelling are unacceptable. Over the entire area of the room, it should fit snugly to the floor.

The positive qualities of this material include its low allergenicity. Being an agglomeration of natural material and the same binders, it is initially environmentally friendly. This allows the use of such material in residential premises, children's rooms, kitchens and other similar places.

Among other positive qualities, the following are noted:

- a long service life of up to 30 years with strict observance of surface preparation technologies where a cork substrate and its installation itself are used,

- resistance to deformation of the material, after the release of the load, the relaxation of the material layer occurs within 2 - 2.5 hours,

- soundproofing properties - the porous structure and elasticity of the source material effectively dampen sounds of a penetrating nature, as well as vibration waves from working electrical equipment and devices. Even with a layer thickness of 2 mm, the material dampens sounds up to 12-14 decibels,

- heat-insulating properties - low thermal conductivity determined its use for insulation of walls, ceilings, floors and other multidirectional planes,

- the material is an antiseptic of natural origin, not exposed to the effects of fungi and lichens, and also does not serve as food for domestic rodents.

A unique property is the ability of the cork to reduce the radioactive background and the harmful effects of other building materials.

A negative factor is the high price of cork materials, which is successfully offset by a set of its positive characteristics and durability.

In addition, the low thermal conductivity of this substrate prevents its use for any underfloor heating.

Coniferous substrates

This material is made from wood shavings and wood chips that have been steamed. When extruding products, no extraneous binders are used; this is the quality of the own resin contained in the wood itself. The materials used and the production method reasonably allow us to consider coniferous substrates as environmentally friendly material.

The main forms of release are rolls and plates. The latter are packaged in packs of 7 square meters with a card size of 59 x 89 cm and a thickness of 3.5 - 7 mm. When laying as a substrate, the seams are glued with construction tape.

Initially, this material was intended for use as a sound insulator, but the revealed ability to dampen shock and vibration loads led to its use as substrates for various floor finishes.

The coniferous substrate under the laminate has a number of valuable positive qualities:

- high soundproof ability creates comfortable living conditions in the room,

- the use of coniferous substrate allows you to save floor heat,

- the density of the tiles allows you to significantly level the unevenness of the base when laying both on a concrete floor and on a wooden one,

- when installing a coniferous substrate, there is no need for additional adhesive compositions, tools and devices,

- the absence of synthetic additives, adhesives and modifiers allows to attribute this material to environmentally friendly,

- during operation, the coniferous substrate holds its shape well, does not sag, keeping its shape for at least 15 years.

A significant drawback of the material is its ability to be moldy in the presence of moisture.

Therefore, we mentioned above the need to use steam protection as part of the substrate. In addition, when using coniferous material, moisture protection is needed between it and the laminate to prevent it from getting wet when cleaning.

Polypropylene foam

This material is the most popular of the class of synthetic products for use as a substrate for a floor finish, including a laminate.

The structure of the material has a bubble structure, which explains its low thermal conductivity and sound insulation properties.

One of the reasons for the high popularity of foamed polypropylene is its low price, which does not indicate its insufficient quality. It quite successfully withstands laminated flooring and tolerably retains heat and sound.

The release form in the form of rolls or sheets is made with a wavy surface, which provides ventilation of the space under the laminate. In addition, with a thickness of 3-5 mm, the substrate successfully copes with the unevenness of the floor base.

One of the disadvantages of polypropylene substrates is the destruction of bubbles under repeated loading. The consequence of this is the flattening of the material with the loss of its basic qualities.

Recently, foil substrates have been widely used, and metallization can be one-sided or two-sided. Such material works at the installation site as a thermos flask, effectively retaining floor heat. The thickness of the substrate in this case is 2 - 5 mm.

In order to avoid isolation of the laminate from the heating elements during the installation of underfloor heating, the substrate must be placed under heat sources, preventing its leakage into the base of the floor. In this case, special importance should be given to the quality of the surface of the floor base, regardless of the material of its manufacture.

Why do I need a substrate for a laminate

Laminate flooring refers to wood flooring, which has the same disadvantages as wood. It is characterized by moisture sensitivity and high porosity. At the same time, the laminate has a lot of positive qualities: it passes air, creating a favorable microclimate in the room, is natural and safe.

Laminate underlay is required for:

- elimination of irregularities,

- increase sound and heat insulation,

- moisture protection.

When choosing a substrate for a laminate, the following should be considered:

- on what basis will it fit

- are there any bumps or floor defects

- parameters of temperature and humidity in the room,

- what laminate will be laid on it.

Depending on the quality of the selected substrate, the life of the laminate also depends.

Main functions

The main functions of the substrate are: improving sound and heat insulation, leveling the floor, increasing the strength of the finish coating and evenly distributing the load on the floor. With its help, the service life of the laminate is significantly extended. Also, the substrate under the laminate makes the finish flooring more wear-resistant, durable and strong.

Screed surface defects

With the help of a properly selected substrate, you can fix defects and irregularities in the concrete screed. It is far from always possible to make the floors perfectly even and smooth. Anyway, in some places small differences will remain on them, which will subsequently negatively affect the laid laminate. Indeed, in the presence of any differences in the base, there will be backlashes between the panels and the floor. That is, in places of maximally large gaps, the coating will sag.

Even small differences of only a few millimeters over time will lead to big problems with the finish flooring. To prevent this, just lay a substrate under the laminate. It will hide all base errors and create a perfectly smooth surface.

Some people think that the thicker the substrate, the better. This is actually a fallacy. Since if the substrate is too thick, cracks form more quickly on the finish, and the laminate simply sags under the pressure of heavy furniture items.

An ideal option is a substrate with a thickness of 3 mm.

Damping vibrational movements of the floor

Laminate floors are subject to oscillatory movements caused by:

- dynamic load (walking),

- sound waves (from occurring noise).

If you do not take any measures to suppress vibrational movements in advance, the locks on the lamellas will quickly fail. In this case, a competently selected substrate for the laminate will solve the problem, which will act as a damper between the finish floor and the concrete base.

Soundproofing

When walking on the laminate, two whole types of noise are created (the one that is heard indoors and under the floor). That is, when someone walks around their apartment, not only its residents suffer, but also the neighbors below. This is due to various factors: the insufficient thickness of the laminate itself (which is only 8 mm), and the floating method of laying it (which creates an additional membrane for transmitting sounds). It is quite easy to solve this problem if you choose the appropriate type for the laminate.

Almost all substrates have good soundproofing qualities and suppress indoor noise. But cork products are considered the best.

Waterproofing

Laminate is a rather capricious material that does not tolerate high humidity. Therefore, before proceeding with its installation, it is necessary to take care of a good waterproofing of the floor.

If the laminate is laid on a concrete screed, it must be dry. Otherwise, condensation will constantly accumulate between the base and the laminate. When choosing a substrate, you should carefully familiarize yourself with its technical characteristics. Most modern materials act as waterproofing, and maintain a favorable microclimate for both the concrete base and the laminate.

To check if the concrete screed has dried, leave a plastic bag on it for the night. If it is dry under it in the morning, then everything is in order and you can proceed with the installation of the laminate. If condensation forms under the bag, you will have to wait a little while until the concrete is completely dry.

Thermal insulation

When arranging a floor covering, it is worth considering the fact that it should be warm and pleasant to the touch. Using a properly selected substrate will help keep warm air in the room.

The laminate itself is a rather warm material. And if you competently choose a substrate with high thermal insulation characteristics, it will be nice to walk barefoot on such a coating at any time of the year.

Is it possible to do without a substrate

When laying a laminate, it is impossible to do without a substrate. Since its absence will quickly put the finish coating out of order (it will begin to creak, bend, cracks will form between the slats).

The only option when the substrate is not needed is the laying of a luxury laminate. Just in this material, the substrate is already glued to the back of the panels. If one more substrate is laid under it, then a too thick cushioning layer is formed, which will lead to deformation of the laminate.

The absence of a substrate under the laminate causes rapid deterioration of the finish.

Polyethylene foam

It is made by foaming polyethylene. It is in great demand due to:

- affordable cost

- high heat and waterproofing qualities,

- resistance to the formation of fungi and bacteria.

Since it is made from synthetic materials, it does not start pests. In addition, this material is easy to cut with scissors and it is convenient to stack. As for the disadvantages of polyethylene foam, it is its low strength and short life. Also, this material does not differ in high soundproofing qualities.

Expanded polystyrene

This type is sold in sheets of small sizes. This material is quite convenient to use and is distinguished by:

- high heat and sound insulation qualities,

- good ability to level the floors,

- moisture resistance

- ability to cope with heavy loads.

Due to the elasticity of the material, it absorbs the vibrations created by walking for many years and makes the finish flooring completely silent. This material is notable for its low cost and excellent technical qualities. Of the minuses, it is worth noting a not too long service life, which is only 6-7 years. Also, it can only be laid on perfectly flat floors.

Polypropylene

The most budget option. It is characterized by low resistance to loads and after a year or two of intensive use, it fails. It is sold in rolls and its standard thickness is from 2 to 3 mm. Advantages include: low cost, resistance to high humidity. It is recommended to be used only in temporary rooms.

Cork

It differs in naturalness and environmental friendliness, due to which it is often used in residential premises (bedrooms, living rooms, children's rooms). Cork substrate is able to cope with any loads, does not lose its shape and acts as a heat insulator.

As for its main advantages, they should include:

- environmental friendliness

- fire safety

- durability.

This material does not decay, and does not deteriorate under the influence of negative factors, thanks to special impregnation.

Among the disadvantages, poor resistance to moisture stands out. Therefore, it is not recommended to lay it in rooms such as a bathroom or kitchen.

Cork substrate is laid only on perfectly flat floors. Otherwise, it will deform and quickly fail. Before laying, the base is primed with a special water-repellent composition.

Bitumen-cork

It is made of bitumen and kraft paper. A small layer of cork is laid on top of it. This material has good sound insulation and resistance to moisture. Also, the bitumen-cork substrate passes air well and prevents the formation of condensate. It is quite expensive, but fully justifies this drawback with a long service life.

Coniferous

Quite popular material, sold in the form of small plates. It is not as flexible as a cork, but it passes air well, creating a favorable microclimate in the room. This type refers to a natural and safe material. It is made of spruce wood. It has a porous structure (promotes natural air circulation), copes well with irregularities on a concrete base. Also, coniferous substrate is considered a good insulation and prevents fluctuations in the movement of the floor. Its only drawback is the high cost. But she completely compensates for this by a long service life.

Combined

In these types of substrates, various materials are used: polyethylene and polystyrene foam. This type is most often used in the arrangement of underfloor heating, when you need a thin substrate with resistance to moisture and good soundproofing qualities.

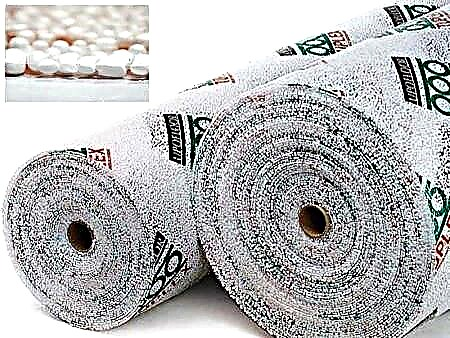

The combined types of laminate substrates include Tuplex products. Externally, the material is a two-layer film, which inside is filled with polystyrene foam balls. Combined substrates are sold in rolls, their standard thickness is 2-3 mm. Their benefits include:

- high strength

- elasticity,

- ability to hide defects of uneven base,

- the ability to maintain the original technical characteristics throughout the entire life cycle.

Cork substrates

Cork substrates are environmentally friendly materials. They consist of granules of cork, which are connected with a special glue. This material is pleasant to the touch and is often used in nurseries or bedrooms, since there are no harmful substances in its composition. The cork does not rot, does not deteriorate, and mold and fungi do not form on it.

A plastic film is bound to creep under the cork substrate, since this material is afraid of moisture.

Depending on the materials of manufacture, the cork substrate is divided into:

- bitumen-cork,

- cork chips

- cork cloth

- rubber-cork.

Cork rubber

Rubber-cork substrate is made of granules of cork and synthetic rubber. The material has good cushioning and soundproofing qualities. Also, it is worth adding to its advantages: flexibility and elasticity, resistance to temperature extremes, fire safety. It is easy and pleasant to work with her.

Polyethylene Foam Substrates

They have high thermal insulation and moisture resistance. This material is easy to fit, as it can be cut according to the required size with scissors. Since the substrate is made of synthetic materials, rodents do not spoil it and insects do not start in it. Also, it is not subject to the formation of mold and fungus.

Substrate thickness

Some users believe that the thicker the laminate substrate, the better. This is actually a fallacy. Since if the substrate is too thick, the laminate will shrink strongly when walking or when heavy furniture items are installed on it. Over time, this will lead to its deformation.

In the construction market, you can purchase substrates for a laminate with a thickness of: 2 mm, 3 mm, 4 mm, 5 mm, 7 mm, 10 mm. But in order to choose the right material, the following factors must be considered:

- thickness should vary between 2 and 5 mm. The choice of thickness is determined depending on the defects and unevenness of the base,

- thickness depends on the materials of its manufacture. When choosing a cork, a thickness of 2 mm is sufficient. When working with polyethylene, it is worth choosing a thickness of 5 mm, since over time it will sag,

- materials with a thickness of 5 to 10 mm are used in cases where it is necessary to significantly increase the heat and sound insulation qualities in the room.

If the substrate is thicker than 5 mm, then over time, the connections of the laminate lamellas will be damaged. Since this flooring was originally designed to bend when walking on it. As a result, cracks will appear on the laminate and the floor will creak strongly.

With an even floor base, a very thin substrate is selected.

Rating of the best substrates

In the modern construction market, a wide selection of substrates for laminate from various manufacturers is provided. The best are:

- Premium Cork. This material is not deformed during the entire period of operation, it is characterized by low thermal conductivity, environmental friendliness and safety. Suitable for laying in bedrooms and children's rooms. It is able to withstand heavy loads. The only thing is, this substrate is not designed for floor leveling. That is, it is recommended to use it only on the condition that the concrete base is perfectly even. Also, for such material, it is necessary to think separately about waterproofing.

- Parcolag. It is able to provide natural ventilation of the floors, is not subject to deformation, has excellent heat and sound insulation qualities. Its only drawback is that it is not suitable for installing underfloor heating.

- Isoplat. Sold in the form of sheets made of pine wood. The material is characterized by good sound and heat insulation and resistance to deformation. It is able to withstand heavy loads, provides natural air circulation, and is resistant to mold and mildew. This type of substrate can be mounted together with a system of underfloor heating.

- It meets all the requirements that apply to the substrate under the laminate. The material is not deformed, has good sound-absorbing qualities, and well absorbs moisture.

- Arbiton. It has a homogeneous dense structure, easy to fit and relates to professional materials that builders most often use.

What kind of substrate is needed for underfloor heating

When arranging a system of warm floors, it is worth considering that a conventional substrate for a laminate will not work here. Since all modern substrates are characterized by high thermal insulation qualities, and together with the additional floor heating, they simply will interfere with each other, reducing their effectiveness.

For the arrangement of warm floors, special substrates are used, the characteristics of which significantly differ from standard ones. They are distinguished by a smaller thickness and higher stiffness indicators. To determine whether a substrate is suitable for arranging warm floors or not, it is necessary to divide its thickness by thermal resistance (this information is indicated on the packaging by the manufacturer). The lower these numbers, the better. Such a material will cope well with the properties of thermal conductivity and will not reduce the effectiveness of underfloor heating.

When choosing a substrate for underfloor heating, it is worth considering its thermal resistance.

The process of laying the substrate under the laminate is quite simple, and even a beginner in this business can cope with it. The styling process itself depends on its type:

- sheet materials are staggered in a staggered manner without overlapping and fixed among themselves with masking tape,

- rolled - overlap the walls, but overlapping strips are not recommended. This type is also fixed among themselves with masking tape.

Laying a lap backing will create bumps on the surface. Consequently, it will no longer be possible to lay the laminate on it.

Before you start laying, you must perform the following steps:

- Carry out preparatory work. The base of the floor is cleaned of dust and dirt and thoroughly dried.

- The prepared material is cut with scissors to the required dimensions.

- The substrate is laid on the base according to the instructions provided by the manufacturer.

- After laying the substrate, you can safely proceed with the installation of the laminate.

Specialists in the field of construction give useful tips and advice to beginners:

- never use damaged material

- rolled materials are wound behind the walls. Thus, the reliability of the finish flooring will be extended and the service life will be extended,

- it is necessary to figure out which side to lay the material. If we are talking about a relief film, then this side is laid on the base. If the material has an aluminum base, then it is stacked on top of the laminate.

When laying the substrate under the laminate, the most important thing is to avoid the coincidence of its seams and the seams of the finish coating.

Which option to choose, only the buyer has the right to decide. The main thing is to carefully read the technical characteristics of the material, read reviews of previous customers about it, compare the cost of products on different sites. But when choosing a substrate, it is worth considering that the durability of the finish flooring will directly depend on its quality.

What is the substrate for?

The lining for the laminate should be laid in connection with the tasks assigned to it:

- Soundproofing. If you do not lay substrates under the laminate, then with each step the sounds will be amplified by a wooden or concrete base. Using an even, soft base, you can get rid of squeaking and small noises. In the 32nd and 33rd classes of the laminate, there are sometimes built-in substrates in the form of insulation glued from the back side. Such material is easier to lay than usual, but a more complex production technology significantly increases its price.

- Surface alignment is another task that a sheet substrate for a laminate should cope with. When installing this coating, it is very important to level the surface, since the durability of the locks will depend on this. The laying technology allows a height difference of 1 m not more than 2 mm. But a too thick substrate, hiding the bumps well, will, at the same time, sag strongly under the weight of the steps. To prevent the seams from spreading out after six months, the floor surface must be carefully prepared before laying the laminate.

- Waterproofing. Laminate is just pressed paper, so even its most moisture-resistant models should not be tested by pouring water, otherwise its panels will simply swell. The substrate under the laminate on the concrete floor is able to protect the coating from moisture coming from the cement base. In general, a concrete screed should be allowed to dry for a month and only then lay the topcoat. You can check the readiness of the screed by laying on its site a plastic film for the night. If it doesn’t evaporate in the morning, the screed has dried out.

- Thermal conductivity. A substrate for a laminate located above a warm floor will inevitably reduce its efficiency, since both it and the coating itself have a fairly low thermal conductivity. Although for the installation of underfloor heating began to produce special substrates. In any case, regardless of the material of manufacture, the thickness of the substrate laid under the laminate should not be more than 3 mm. True, there are unscrupulous masters who, trying to hide the flaws they made while leveling the base, use thick linings (4-5 mm). Such an object looks perfect upon delivery, but six months later, the laminate begins to creep at the seams.

Coniferous tiles

In recent years, another novelty has appeared - a coniferous substrate under the laminate. It is still very expensive, it can hardly be found in stores, but if someone comes across the name “isoplat” on the counter, then this is it. The novelty is advertised as an exceptionally environmentally friendly material that breathes well, and therefore does not suit the greenhouse effect under the floor covering.

But from the point of view of elasticity, it is still significantly inferior to the classic cork.

It should also be taken into account that coniferous tiles have a minimum thickness of 4-5 mm, which conflicts with the requirements of the manufacturers of the laminate itself.

The wooden substrate for the laminate is available in the form of tiles that need to be laid diagonally.

Foil backing

This material is appreciated for the fact that it can perfectly retain heat. On sale you can find one-sided or double-sided types of foil substrates, consisting of two layers: foil and polyethylene foam or polystyrene.

Foil substrate is ideal for rooms where there is a possibility of moisture penetrating into the screed (bathroom, kitchen, basement).

Benefits:

- Thermal insulation of floors is increased by 30%.

- It is an additional waterproofing layer.

- Increased moisture resistance, so laying an additional layer of plastic film is not needed.

- Prevents mold and mildew.

The lack of such a substrate can be considered its inability to recover, that is, under physical influence it will not take its previous shape, and air voids can form in these places.

Combo Substrates

Quite interesting is the material in which polystyrene foam and polyethylene are present at the same time. For example, in the well-known Tuplex brand, polystyrene balls are located between two layers of polyethylene. In this case, the thickness of the substrate for the laminate is standard 3 mm, and the material itself is sold in rolls. Due to its structure, this material allows the room to be ventilated.The top layer does not let moisture in, and a very thin bottom layer allows it to pass to the bubbles, from where it is brought out through technological gaps.

There are other combinations, for example, some manufacturers produce a laminate, to which rubber is glued from below, coated on the opposite side with a thin non-woven material. On the screed, it glides well, without warping, and while walking perfectly absorbs noise. Of course, the cost of such an "advanced" laminate is much higher than usual.

Laying the substrate under the laminate

Laying the substrate under the laminate consists of the following steps:

- On a fresh concrete screed, you first need to lay a thin plastic film, and for old screeds, you can skip this step.

- Remove all dirt and dust from the floor by working with a vacuum cleaner and make sure that the base is dry.

- You can cut the substrate with a construction knife or ordinary scissors.

- If the substrate material allows, an overlap must be made on the walls, which will then be hidden under the skirting boards.

- In an attempt to compensate for irregularities, you cannot duplicate the layers of the substrate. Leveling can only be done with screed, plywood or other acceptable method.

- If the substrate has a corrugation, then it should be turned down, then there will be less unevenness.

- Foil materials should be laid up with the reflecting side up.

- Laying must be done end-to-end without overlapping sheets.

- To prevent the substrate from accidentally shifting during operation, it can be fixed with double-sided tape to the floor.

Video about laying a foil substrate under a laminate:

Which laminate flooring do you prefer and why? Share your experience and opinion in the comments - we are interested in your opinion.

You will be interested in:

Some apartment owners, when searching for flooring, are trying to find something unusual that would be both practical and look beautiful.

Laminate flooring has become an extremely popular flooring in urban apartments and country houses. It is even more popular in a variety of offices and public places. The range of laminate flooring is divided into a number of ...

Types of laminate substrates

The modern construction market offers a wide range of underlying materials that differ in the types of raw materials, form of release (sheet, roll), origin (artificial, natural) and other characteristics. To understand which substrate is best for the laminate in specific operating conditions, you need to familiarize yourself with the following factors:

- Features of the apartment.

- The thickness of the substrate.

- Stacking difficulty level.

- The cost of the selected building material.

- Declared lifetime.

- Ecological purity of the material.

- Resistance against aggressive environments, fungi, rodents, harmful microorganisms, etc.

In the rating review, you will learn not only about popular samples, here we will talk about materials developed using innovative technologies.

Bazalux

Cork substrate Bazalux high quality Portuguese brand EGEN. Material - of natural origin, environmental friendly, does not emit harmful substances. Thickness - 2mm, 3mm. The substrate goes on sale in rolls with a total area of 10 square meters. The underlying material has enhanced acoustic properties, the sound insulation level is 17 dB, perfectly retains heat.

- Ecological purity of natural material.

- Ease of styling.

- Excellent performance.

- The floor is warm, does not creak.

- Can be laid on uneven floors.

- Choice in thickness from 2 to 3 mm.

- The absence of a foil layer.

Arbiton secura extra

The substrate of the Polish manufacturer is the best option for laying laminate flooring in rooms with medium floor loads. Using Arbiton Secura Extra, small irregularities (not more than 2 mm) of the original base are easily eliminated. The material of manufacture is extruded polystyrene. Available in separate sheets with a thickness of 3 mm. thanks to a special system of grooves, air circulation is ensured, the likelihood of mold spots, fungi is reduced.

- Adequate cost.

- The comfort of walking on the laminate.

- Excellent heat, sound, vapor barrier.

- Softening shock and static loads.

- Environmental friendliness, absence of extraneous odors.

- Stability, durability of connections.

- During installation, additional sealing is not required, there is an adhesive tape.

- Easy laying (there are special marking lines on the surface).

- Fragility of the structure.

STEICO

Coniferous flooring under the STEICO conifer laminate is made in Poland. This underlying layer is most often used when repairing an apartment, building a house at the stage of laying the floor. The flooring material “Steiko” is shredded coniferous wood pressed into sheets.

- The material provides heat and sound insulation, effectively absorbs the sound of steps.

- Ecological purity, naturalness, no emission of harmful substances with increasing temperature of more than 90 ° C.

- Mold does not form, fungus.

- Large selection of plates in thickness from 4 to 7 mm.

- Universality.

- Easy styling.

- It is possible to even out irregularities in the base of 3 mm

- The fragility of the material during transportation.

- High price.

PROFloor 5mm

Universal substrate under the laminate PROFloor is made in Ukraine. With the help of this flooring, the masters smooth out irregularities of the base with a height of up to 2.5 mm. Production material - polystyrene does not absorb moisture, perfectly protects the room from noise, saves heat.

- Low price.

- Compliance with the declared characteristics.

- The substrate does not emit unpleasant odors.

- Easy quick installation.

- Universality of application.

- No flaws were identified.

Quick step basic

Quick-Step Basic under the laminate is available in Russia. The insulating layer of the foamed structure in light green with rolled polyethylene film goes on sale in rolls measuring 15.0 x 1.0 square meters. The thickness of the material is 3 mm. Using the Quick-Step Basic extrusion substrate, possible irregularities in the concrete base are smoothed out to a maximum of 2 mm.

- Convenience of work.

- High sound absorption.

- Effective protection against steam.

- Universality.

- Costly flooring.

Tuplex Professional

A high-quality substrate under the Tuplex laminate with a thickness of 3 mm consists of three layers: a microperforated membrane film, balls granulated from foam, PVD (high-pressure polyethylene).

- High quality workmanship.

- Sound absorbing properties.

- Isolation from steam.

- Smoothes out irregularities in the concrete base.

- It withstands increased loads from heavy furniture.

- Profitability (it is not required to buy an additional plastic film for isolation from moisture).

- High price.

- When cutting sheets, many scraps are formed.

Profitex

The underlying layer under the laminate Profitex Russian production. The thickness of the three-layer material is 3 mm. The first layer is 40 microns ultra-thin polyethylene, the second is polystyrene granules, the third is a multilayer combined film. The substrate "Profitex" has a high level of protection against moisture, sound insulation. The compression rate under mechanical loads is 10%. The service life of this substrate is limited by the time the laminate itself is used.

- Not afraid of moisture, eliminates excess steam.

- Excellent sound absorption from steps, good cushioning.

- It withstands high loads from furniture weight.

- Thermal insulation.

- Does not emit sharp unpleasant odors.

- It serves a long time.

- Easy to fit.

- High price.

Solid

The universal Solid polystyrene substrate for a laminate is sold in the form of sheets with a thickness of 5 mm. The overall size of each sheet is 1.0x0.5 square meters. the material is capable of absorbing irregularities in the foundation of the concrete floor of not more than 2.5 mm

- Affordable price.

- Excellent workmanship.

- Durability, reliability.

- Easy installation.

- The structure of polystyrene is quickly restored after unloading.

- Practicality.

- Resistance to excessive moisture.

- A light weight.

- Fragile sheets often break when transported.

STENOPHONE

Cork substrate "Stenofon" perfectly protects the laminate from the negative effects of the concrete base. This lining material is made of natural materials - bark of balsa wood. The pressed crumbs provide effective sound insulation, keep heat indoors. It is not recommended to lay the cork backing on a fresh screed.

- Versatility, suitable for installation in panel multi-storey buildings.

- Durability of the material.

- Ecological cleanliness.

- The stenophone is not suitable for installation in rooms with high humidity.

- Hypersensitivity to roughnesses of a basis.

Sound guard roll

Sound Guard Roll Damper Flooring is made in Russia. Material differs in density, elasticity. The composition of the canvas includes polyester fibers interwoven with each other in a chaotic manner. The main purpose of this substrate is to reduce noise, heat conservation, damping properties. Most often used in the arrangement of floors in high-rise buildings with concrete floors. Perfectly conceals bumps in the screed of the subfloor. The separation layer of this type of hypoallergenic is recommended for installation in bedrooms, children's rooms.

- Effective smoothing of possible surface defects of the base under the laminate.

- Depreciation.

- Environmental friendliness.

- Decent workmanship.

- Thin layer.

- Relatively high cost.

- A lot of weight.

- Complex installation (one master can not do without an assistant).

- The filler gets much sleep during transportation and installation.

Penoterm Porileks NPE

The substrate of domestic production "Penotherm" is much cheaper than imported analogues and is not inferior to them in quality, technical, operational characteristics. Foamed material with a thickness of 2 or 3 mm is produced in sheets and rolls with a length of 10 meters or 25, respectively, and is laid in one layer. The substrate under the laminate of this type is an excellent noise insulator, retains heat, the floor does not creak.

- High quality workmanship.

- Adequate cost.

- Versatility (fits the laminate of various companies).

- Easy installation without the formation of waves.

- There are no flaws.

Isolon foil

The material for the manufacture of the substrate for the Izolon laminate is closed-porous foam. Due to the simple production of this material has a low cost. At the request of customers, the material is available with double-sided and single-sided lamination. The foil substrate is coated with a layer of polished aluminum foil having excellent reflective properties.

- Cheap stuff.

- Excellent thermal resistance of foamed polyethylene.

- Low thermal conductivity.

- Protection against steam, moisture, excessive noise.

- Easy installation - self-adhesive.

- Light weight.

- Environmental friendliness and safety of use (synthetic adhesives are not used in the manufacture of the foil substrate Isolon).

- When laying, waves often form, the material must be allowed to sag for several hours.

Isoplaat Silent Running

Isoplaat Silent Laminate underlay is designed and manufactured in Estonia. The material is made on a wood-fiber basis. The main raw materials are cellulose, natural wood waste. Most often, this layer is used when laying the laminate on uneven surfaces. The structure of the material levels the floor due to deformations of the lower layer. as a result, the finished flooring does not creak, does not crack while walking on the floor.

- Environmental safety of the substrate from natural raw materials.

- Heat-, soundproofing properties.

- Effective ventilation of the space under the laminate.

- No jamming if excessive moisture gets under the floor.

- Resistance against the formation of mold, fungi, reproduction of pathogenic microbes (during production, the material undergoes special treatment with antiseptic agents).

- Elimination of any irregularities with large differences in the rough floor.

- Large selection of material for sheet thickness from 4 to 7.5 mm.

- There are no flaws.

Arbiton eco max

Arbiton Eco Max laminate flooring made in Poland. High-quality environmentally friendly gasket from extruded raw materials XPS (polystyrene) is designed for installation under floor coverings: parquet, laminate. Products are delivered to the distribution network in sheets of dimensions: 790 × 500 × 5mm. Tiles are fixed to each other using special grooves, which ensures high-quality circulation of air flows under the main coating. Compared to analogs from natural materials, Arbiton Eco Max is characterized by increased fire safety. Polystyrene tiles do not support open fire, do not ignite spontaneously.

- Excellent soundproofing.

- Low thermal conductivity.

- Durability, reliability.

- No deformation when squeezed under the weight of heavy objects.

- During installation, the elements do not crumble, do not break.

- In addition to the high cost, no flaws were found.

Which substrate under the laminate is better to choose

When choosing the most suitable underlying layer for flooring in specific conditions, certain factors must be taken into account:

- If your apartment is located on the ground floor, it is better to buy a substrate for a laminate with improved thermal insulation performance.

- When arranging children's rooms, it is recommended to give preference to materials that provide sufficient insulation from noise.

- In rooms located above bathrooms and other rooms with high humidity, it is best to use moisture-resistant materials as a substrate.

Which substrate under the laminate is best to install in your apartment, the owner decides. Before buying, we recommend that you familiarize yourself with the technical and operational characteristics of the selected option, user reviews, listen to the recommendations of experienced craftsmen.

The procedure for laying the substrate

Such an operation must be started from any angle and act in this case as in the case with the installation of floor tiles:

- if a sheet substrate is used, place its first card in the corner, make sure that the corner is not skewed. If it is, mark the cut line for the entire row and cut off with a clerical knife according to the marking,

- when working with rolled material - make the last joint with an overlap of 7 - 10 cm and, using a ruler, cut a double layer of material for the entire length. Removing narrow segments, we get the perfect joint even with uneven cutting,

- glue all joined edges with adhesive tape along the entire length, forming a sealed floor covering with a substrate,

- fix the substrate with tape to the walls around the perimeter.

At the end of laying the substrate, you can install laminate boards.

Tips & Tricks

When installing a floor with a laminate, a number of measures necessary for execution can be recommended:

- When installing a topcoat from this material on a straight wooden floor, remove the old paint. After this, it is advisable to tear one or two boards and check the condition of the supporting elements - lag. If rotting is detected in at least one place, you will have to completely dismantle the old coating and replace the damaged logs. At the same time, check the sufficiency of thermal insulation and, if necessary, replenish its level using expanded clay, blast furnace slag or foamed sand. Re-close the floor with the same boards (if there is no need for replacement), carefully fix them with screws, recessing the heads into the body of the boards.

- When installing underfloor heating, it must be borne in mind that most heat carriers are afraid of floor irregularities, especially film ones. And the substrates here are not salvation. It will be correct to arrange self-leveling screeds reinforced with fiber shavings and no longer think about bumps. Forced repairs with replacement mats will cost several times more.

- It is necessary to take into account the requirements of SNiP so that the floor level in all mating rooms is the same. This is easy to consider when building a house. And when performing repair work in a separate room, it should be remembered that the minimum thickness of a laminate with a substrate of simple polystyrene foam is 7 - 8 cm, and take this into account when performing work.