The Russian bath is appreciated all over the world and it is the first place where guests are taken to relax after heavy negotiations, lengthy excursions or other tedious activities. The article will focus on the design features of the stoves for the bath, so that each owner can easily choose the ideal heating installation, while achieving the maximum quality of steam in the steam room and efficient heating of other rooms in the building.

Interest in self-construction

Often, a bathhouse is just a place to relax, where our compatriots come to relax, have fun, take a few photos and nothing more. But given how much people love the bathhouse, they often have a desire to complete construction work on their own.

They also want to do the installation of a sauna stove with their own hands, and therefore they simply can not do without taking into account all the parameters and individual design features. First of all, such a desire arises due to the high cost of the finished stove, which can be bought in specialized stores.

The article will take into account all the nuances of creating bath stoves:

- requirements for the main structural elements,

- appearance,

- Features related to design and production.

Given the diversity of production capabilities, today distinguish the design of the furnace for a bath made of metal, cast iron or brick. Each of them has its own unique operational characteristics and features.

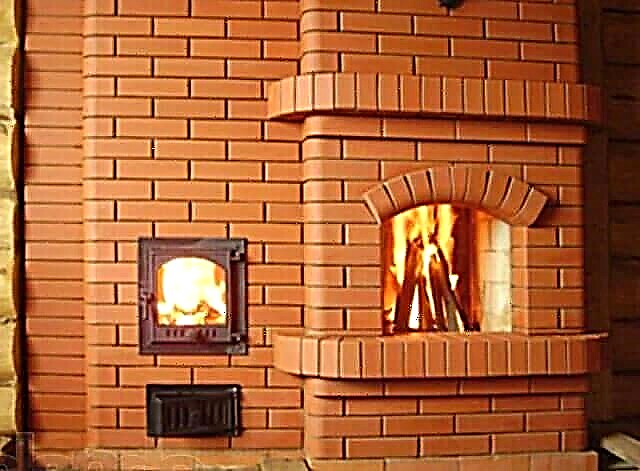

Description of a brick sauna stove

According to the standard, a brick oven is assembled from the following functional elements:

- firebox - is a hotbed of fuel combustion and therefore consists of refractory bricks. When laying, all bricks are coated with clay-sand mortar,

- ashpit - is placed under the furnace of a heating cooking stove and performs the function of regulating the air supply, and is also necessary for ash removal,

- cast iron or steel grate installed directly above the firebox,

- boiler or another water tank that, after heating, can be used in a washroom or for other purposes,

- chimneycomplemented by a latch for traction control

- the doors, as well as other structural elements installed during the laying of bricks.

Brick ovens remain quite popular to this day. To begin with, it is worth saying that the brickwork has a huge weight, and therefore it is necessary to pour a quality foundation under the oven. On such a base, the stove can be laid without using mortar in the first layer of brick. Further, a solution is needed to create durable walls that will be load-bearing (similar to houses). From these walls the main compartments will be erected: a furnace and an ash pan.

Other elements of the furnace construction are laid using a specialized solution, the main components of which are clay and river sand. The standard cement-sand mixture cannot be used, since it is not able to withstand the thermal load created by it.

In some cases, the wall thickness can exceed one brick, but most often, with proper installation using high-quality clay-sand mortar, one brick is enough to get a solid and reliable design. The chimney of a brick furnace can be laid out from the same brick, or installed separately, but in this case the pipe will be asbestos-cement or stainless steel.

It is important that the material has enhanced thermal insulation and refractory properties. In addition to the latch for traction control in the pipe, it is necessary to make additional holes in the chimney, the size of which will be approximately 15% of the pipe area. This is necessary in order to avoid carbon monoxide poisoning seeping through cracks in the brickwork and chimney.

How to prepare mortar for refractory masonry

The preparation of the solution for laying the bathhouse furnace is a process that requires special care and clarity in actions, since this substance will have to withstand the thermal load of up to 10,000 degrees Celsius and more during operation of the furnace. The process does not look like a simple mixture of clay with sand and water, because before applying the solution will be tested and not the fact that once.

According to the standard, the solution is prepared and checked as follows:

- Clay is placed in a container with a slight addition of water and kneaded until a homogeneous mass is obtained.

- A ball is rolled from the resulting solution, with a diameter of not more than 5 centimeters, and then crushed into a cake with diameters of about 10 centimeters.

- At room temperature, the cake is dried for 3 days.

- After the indicated time, the cake is inspected for cracks in its structure. If there are none, then the cake is additionally thrown onto the asphalt from a height of 1 meter. The ball, remaining intact, indicates the suitability of the mortar for use in the brickwork of the sauna stove. If one of the verification conditions is not fulfilled, then you need to add river sand to the solution.

Steel and cast iron stoves for a bath

Considering the main options for stoves for a bath, owners most often are inclined towards the fact that you need to install a structure made of metal, steel or a cast iron alloy (for more details: "How to choose a cast iron stove for a bath - tips and tricks").

The reasons for this are the following advantages of these materials:

- compact design compared to masonry, which occupies a large area,

- the production metal and alloys have much higher heat transfer, and therefore the furnace heats up several times faster,

- the entire design of the furnace is assembled at the factory, and therefore the owner of the bath can only install it, which takes less time than the independent creation of brickwork,

- There are a huge number of forms and structural refinements that can be implemented in the manufacture of a metal bath furnace. If you have the appropriate skills, you can even create your own project of a metal sauna stove for the individual characteristics of the existing building.

According to the standard, a set of functional elements in a metal furnace is similar to that of a brick version. However, if we take a closer look at the drawings for bath furnaces made of metal and alloys, it immediately becomes clear that each functional element has individual operational features (for more details: “Drawings for a bath furnace made of metal - we build our own furnace”).

In shape, a metal furnace can be not only strict in the form of a square or rectangle, but also rounded. For this, the following materials are used in production: welded plates of steel or cast iron, or solid pipes from a thick layer of steel.

The furnace in this design is made of steel, and the thickness of the metal for the furnace in the bath should be from 5 millimeters. In exceptional cases, when special heat-resistant steel is used, the thickness value can be reduced to 3-5 millimeters. A modern furnace furnace consists of a main source and a secondary compartment, in which the fuel remaining after the first stage of combustion is burned. Two-stage combustion increases the furnace productivity by 20%, and also reduces the amount of harmful substances released during the combustion process.

An important nuance in the operation of a metal bath furnace is that it must be trimmed from the outside to increase operational safety. The main disadvantage of a metal furnace in a bath is that the material is not safe when heated. For example, it can be burned with careless handling.

The problem is solved in one of the following ways:

- The stove can be lined with refractory bricks on the outside. The complexity of installation in this case is to carry out a bunch of brickwork with a metal frame. This method, even with its complexity, is very popular, because you can buy material and lay it yourself.

- Otherwise, a special refractory screen can be installed on the furnace body. The advantage of such a screen is that it not only protects from a hot metal surface, but also provides an even distribution of warm air masses within the bath.

We must not forget that the most important element in the operation of the furnace is the stones, laid in order to create the steam, which is necessary for effective procedures. When choosing stones, you should pay attention to their surface texture. They should have a smooth surface with smooth lines without sharp edges and various defects (notches, cracks, chips).

Even size and weight matter. The rule for selecting this element requires the presence of stones of several weight categories at once. It is best to put in one bookmark one stone from 1 to 8 kilograms in mass. A peculiar cone is laid out of them, on the very bottom of which the most massive stones lie, followed by a decrease in their size as they move to the top.

General preferences for all types of stoves

A number of individual features of bath furnaces form a set of requirements that are established regarding the design of the furnace:

- the possibility of choosing individual sizes allows you to place the heating structure in paired compartments of even a very small size,

- the furnace power should optimally be such as to not only heat the steam room, but also a number of other rooms,

- fuel consumption for heating a cubic meter of the room should be minimal,

- the best stoves warm up quickly and hold the required temperature for as long as possible (read: "Which stoves are better for a bath - an overview of the advantages and disadvantages of popular stoves")

- finally, the stove should provide a bath with hot water, etc.

Specialized classification of furnaces for baths and saunas

There are a number of different criteria that have contributed to the development of a large number of types of stoves for baths and saunas. Consider the main classification types to understand what else are bath stoves.

The room heating method determines the following types of furnaces:

- Black - stoves without a chimney, in which smoke is discharged exclusively through the room and natural air openings: roof, floor, window and door openings.

- Whites - more common stoves, because their design involves the installation of a chimney.

According to the method of heating water, the following furnace designs are distinguished:

- with a water tank suspended above the furnace or integrated into the housing itself. As a tank, a boiler or tank is usually used,

- with a coil drawn through the furnace through which cold water moves and is already collected in a special container when heated.

By the method of placing stones in a special compartment under them:

- in the case when the heater is closed, the stones are laid directly in the chimney and this is not the best option,

- with the open type, stones are laid in special cast-iron or steel containers placed above the firebox.

By type of fuel combustion:

- periodic - allow you to start the procedure in the steam room only after all the fuel has burned out,

- permanent - more popular, because they can maintain a constant combustion process, throwing up occasionally selected material as fuel. When using them, the only question that arises is how exactly the furnace will be placed: inside the furnace or it will be taken to the right room of the bath to simplify the process of filling the fuel.

Finally, stoves are divided into several categories according to the type of fuel used:

- solid fuel - on wood, peat or coal,

- liquid fuel or gas - on diesel fuel, balloon or liquefied gas (more: "How and what to choose a gas stove for a sauna"),

- electric - furnaces providing high-quality heating due to heating elements operating from the electric network.

There are other varieties of bath stoves, but all of them are experimental and in many respects lose to brick and metal structures, which are given the main preference for the owners of their own baths and saunas.

Total

If you correctly use the information presented in this article, then you can choose the most efficient, reliable and durable bath stove. For this, it is necessary to focus on all the specified criteria when purchasing. Also, if you wish, you can entrust the choice to specialists who will take responsibility not only for the purchase, but also for the installation of the furnace with its subsequent commissioning.

Features

Wood burning stoves have always been popular in our country. Their relevance is due to multitasking. A wood-burning stove not only perfectly heats the room, but also forms the most comfortable microclimate in it.

Currently, high-quality wood-burning stoves are made not only by domestic, but also by foreign companies. They are made from different materials. There are also original wood-burning stoves for the bath, which have non-standard and interesting shapes. By placing such an aggregate, you can update the appearance of the bath and give it a twist.

A feature of the wood stove is that it must be very carefully installed, avoiding any errors. Otherwise, the unit simply will not warm up to the required level. In addition, it may happen that the stove does not fit into the layout of the building. To avoid such a bleat, it is necessary to correctly select the units and also correctly install them.

Another distinguishing feature of wood stoves is that provided that they are installed correctly, they quickly and qualitatively warm the steam room. In addition, the maintenance of such devices is very inexpensive and does not cause much trouble.

Wood stoves can be based on continuous or intermittent heating. The first option is recommended to be installed in the bath only if the walls in it do not differ in large thickness, and specimens with periodic heating are calculated for a considerable amount of stone backfill.

It is worth noting that today wood stoves come in a variety of modifications. They have different foundations and differ in the principle of action. Any buyer has the opportunity to choose the best option.

Wood-burning stoves, like other units, have their own advantages and disadvantages. And you must know about those and others if you decide to purchase a similar stove in the bathhouse.

To begin, consider what advantages are typical for these devices:

- Typically, such stoves are small in size, so they can be selected even for a very modest bath, designed for a small number of people.

- Modern manufacturers offer stoves that not only cope with the main task, but also effectively complement the atmosphere in the bathhouse, completing it.

- As mentioned above, a high-quality wood-burning stove is able to quickly warm up the room, which is especially important for a bath unit.

- You can kindle a wood stove at any time convenient for you.

- It should be noted a large selection of wood stoves.

- Wood stoves are environmentally friendly because they operate on a safe type of fuel.

- Of course, gas or electric stoves are much less whimsical than wood stoves, however, many homeowners choose units that run on natural fuel for their baths. This is explained by the fact that wood-burning stoves are not dependent on electricity or a gas pipeline, which may be absent in a certain area.

- Wood stoves operate on inexpensive and common fuels.

- Most modern wood-burning stoves have an affordable cost, so almost every consumer can afford them.

Despite the efficiency and environmental friendliness of wood stoves, they also have some disadvantages that dissuade many buyers from buying them.

Let's consider them in more detail:

- First of all, it should be noted the fact that the work of such a stove will have to be constantly supported - toss firewood. Otherwise, after they are completely burnt, the bathhouse will simply begin to cool gradually.

- Many masters note that these types of furnaces are quite complicated in terms of installation. At the slightest error, the design will not work correctly, which can lead to negative consequences.

- The wood stove must be supplemented with an exhaust chimney, since a lot of smoke is emitted during the burning of firewood.

- Even the most expensive and beautiful wood-burning stoves are fire hazardous.

- The inconvenience in the use of such stoves is that before they are started, firewood must be prepared in advance and stored properly. All this often takes a lot of time.

- The chimney of a wood stove will have to be periodically cleaned.

- Wood stoves are quite moody, especially when compared to units that run on gas and electricity. Firewood models must be installed on special screens, and the space surrounding them must be carefully protected from overheating. You will also have to make sure that the doors of the device always remain open during the combustion process.

As you can see, wood stoves have more pros than cons.

Many problems with such devices can be avoided if properly installed and properly operated. Of course, you should take care of the fire safety of the unit.

Brick stove

Such structures are distinguished by their large weight (up to 1200 kg) and impressive dimensions. The massiveness of the bath heating unit is primarily due to the thickness of the brickwork. The design consists of the following elements:

- firebox laid out of refractory material,

- cast iron or steel grate,

- ash pan for collecting ash,

- a coil in which water is heated,

- chimney.

A prerequisite for equipping a similar furnace in the bath is the construction of the foundation. Such a base will well support the weight of the structure.

For the construction of a sauna furnace, two types of brick are necessary: refractory and ordinary. In addition, it is worth stocking up with clay and sand to prepare the solution. When building a furnace for a bath, cement is not used. This is due to the low resistance of the material to high temperatures, as a result of which the masonry with cement mortar undergoes rapid destruction.

Brick stoves have several advantages:

- good ability to warm up and retain heat for eight hours (this period is conditionally determined, because its duration depends on the maximum temperature and the initial dimensions of the unit),

- the possibility of heating a large steam room,

- high fire safety.

The disadvantages of brick kilns include the following characteristics:

- the kindling time, which can be measured for five hours, if you want to create high temperature in a large room,

- massive structure, occupying a sufficient area of the steam room, and the need to build a foundation for it,

- the complexity and high cost of construction work.

Metal aggregates

Those bath owners who want to quickly heat their rooms with low fuel consumption can pay attention to bath stoves made of metal. In addition, these devices are characterized by:

- lack of carbon monoxide production,

- fire safety

- durability

- compactness.

It is the latter property that determines the decision to purchase a metal furnace for a small bath room. A mobile welded structure can be successfully assembled in any convenient place, and then it is easy to transfer it to the installation site.

Depending on the frequency of use of this or that unit, bath metal stoves are conditionally divided into cold and hot.

The first option is usually installed in a room that must be constantly heated. Such metal stoves for a bath are heated for a long time, and therefore do not pose a danger as a source of burns. The heating temperature can be adjusted, although the maximum limit rarely reaches levels above 50 degrees.

In two decades, the single-chamber design has been transformed into a device consisting of several fuel combustion chambers. The furnace of the modern sample is more perfect, because it is characterized by a 20% increase in efficiency. With the independent manufacture of such an aggregate, it is necessary to use plate steel or cast iron.

If occasional use of the bath is expected, then you need to choose a hot version of the stove. The device at the stage of heating is able to instantly reach the maximum temperature (≤100 ̊С). This mode is enough to take bath procedures from time to time. However, it should be noted that due to the inability to adjust the temperature, excessive overheating of the room occurs.

Metal stoves for a bath have a number of main advantages:

- heating speed,

- compactness and mobility,

- saving time, money and effort during installation.

Not without a device made of metal and some disadvantages. Among them, note the following:

- poor heat storage and quick cooling,

- the need for continuous support of fuel combustion,

- inability to heat large rooms,

- to prevent thermal shock requires the installation of double walls with an air gap,

- low fire safety.

Types and classification of wood stoves

In addition to the principle of operation, wood stoves are classified according to the material used in their manufacture:

- cast iron wood stoves. Most often used as an additional or extreme heat source for the target room. Combustion products are diverted outside the house using a sleeve or corrugated chimney,

- devices made of heat-resistant steel alloys. They allow you to create a point source of heat, quickly gaining heat from the flame, but also giving it away just as quickly. Like cast iron, they belong to the class of non-heat-intensive furnaces,

- brick stoves for firewood. The most effective option for efficient heating of the living space. Heats the room slowly, but also gives off the accumulated heat for a long time. This principle allows us to classify brick kilns as a class of heat-efficient heating appliances with high efficiency.

According to their purpose, wood stoves are divided into 3 main categories:

- performing a decorative role or used for local heating of an apartment building and cooking,

- used for heating utility rooms or individual non-residential buildings,

- used in baths for heating stones.

Stone, steel and cast iron are widely used for the manufacture of wood stoves of all narrow specializations, although they cope with the task with different efficiencies.

Metal wood stoves for home and bath

Household wood-burning heating stoves have gone from their prototype, bourgeois, to high-tech thermal structures embodied in a flawless industrial design. Fireplace stoves retained their decorative qualities, in most models the firebox is fenced off by heat-resistant glass, allowing you to admire the tongues of the flame. The addition of convectors and the revolutionary transition to continuous burning can be considered relatively new structural elements.

Steel heating and cooking furnaces are equipped with regulators of primary and secondary air supply, which allows you to adjust the combustion rate of the fuel, adjust to its type, humidity and other characteristics. The furnaces of modern steel wood-burning stoves, in order to increase the heat capacity, are covered from the inside with a layer of heat-resistant material that absorbs and retains primary heat. Parallel heating due to convection and thermal radiation allows you to fully heat the room in which the stove of this design is installed, using a relatively small amount of firewood.

Advantages of steel furnaces

- universality. A huge number of models from various manufacturers will allow you to choose a wood stove for heating and cooking, Russian and Finnish saunas,

- ease of installation. Installation does not require laying the foundation and is possible in any room that needs an additional heat source,

- durability. The casings and the furnace are made of steel with a high chromium content, which ensures a long service life even in difficult operating conditions,

- design that allows you to organically fit the stove into the interior of almost any room.

The disadvantages include

- low heat capacity, even for advanced models. The stove warms while the fuel burns in it,

- compact sizes. Only one room will be heated at a time, which turns into a dignity, when it comes to the bath.

Steel wood-burning stoves are an ideal choice for a bathhouse, sauna, and a country house unused in winter. The average purchase and installation cost depends on the manufacturer and model and starts from 10-15 thousand rubles.

Cast Iron Wood Stoves

Fire-resistant cast iron wood-burning stoves warm the room more slowly than steel-sized analogous ones, but much faster than brick counterparts. In the assembly of finished castings, the groove system and special sealant are most often used, which provides reliable fixation of the body parts and the furnace elements. The cost of such furnaces is higher than that made of metal, but there are more advantages.

- excellent ratio of heat capacity and thermal conductivity, providing a smooth and long-term warming up of the room,

- compact size, which is critical for small living spaces and baths,

- high resistance to physical and chemical external influences, ensuring long-term operation,

- there are models with an external firebox and more contact ones with a built-in one, which allows you to choose the best option for each specific bath,

- more expressive in comparison with steel counterparts design and presentable appearance. Many models, mainly of overseas production, are coated with colored enamel,

- universality in the role of a furnace for a bath or sauna. The only requirement is that the heater must be made of the appropriate type of stone.

- the average weight of a cast-iron wood-burning stove is from 100 to 200 and more kg,

- require a sufficiently high chimney with sufficient draft,

- may crack from sudden cooling. Protection against cold water entering the housing is required,

- require installation in a sufficiently dry room or anti-corrosion coating,

- for a competent and safe installation in a house or a bath, you will have to attract a specialist.

The average purchase and installation cost starts from 20-25 thousand rubles and practically does not have a “ceiling”, especially for European-made models.

Brick wood stoves

Depending on the destination, there are many options for the construction of brick baths on wood. These diverse designs are combined by the presence of such mandatory elements:

- foundation foundation

- bricked body,

- a combustion chamber separated from the ash pan by cast-iron grates,

- a chimney of complex configuration intended for the removal of combustion products.

The main destinations affecting the configuration of a brick wood-burning stove are:

- heating the house, with the placement of the furnace in the center of the construction of several rooms,

- use of a wood stove for cooking,

- warming up stones in a bath or sauna,

- combined use for heating, with the possibility of cooking.

All these features make it necessary to lay a place under the furnace at the stage of designing a house or bathhouse.

Among the owners of private houses and summer cottages, combined solutions combining a fireplace with a traditional stove and stoves with a boiler for heating water are becoming increasingly popular. Equally popular are traditional Russian stoves.

Advantages of masonry wood stoves:

- the ability to heat several rooms and floors at once,

- long return of the saved-up heat and high inertia,

- creation of a comfortable indoor microclimate, with optimal humidity,

- universality, and the ability to choose the characteristics you need.

It is enough to follow simple requirements for operation, and the period of use of the furnace will be calculated more than one dozen years.

The main disadvantages are:

- DIY construction complexity

- quite tangible time and material costs for the construction,

- bulky, in comparison with wood stoves made of steel or cast iron,

- the inability to heat the room for a short period of time.

The cost of construction will vary greatly depending on the region.

What to look for when choosing a wood stove

To facilitate the selection of the best option for a wood-burning stove, follow these instructions:

- Decide on the functionality required of the furnace and the approximate area of the room in which it will be installed. To heat one room or a small bathhouse, stoves made of steel and cast iron are suitable, for a large house on two floors or a spacious steam room, brick stoves should be chosen,

- count how often the oven will be used. If we are talking about a country cottage or a bath, then decide whether you will spend time here in the winter months. If not, it’s worth choosing between metal and steel furnaces that allow you to quickly warm the room,

- choose a place to install or lay it in the project before the start of building a house or bath. For steel and cast-iron furnaces, it will be important to choose a place that makes it possible to equip the hood as simply as possible. When choosing locations for bricks, you can’t do without consulting a master stove-maker,

- Decide on the budget allocated for the purchase of the furnace. Often this becomes a decisive factor in the choice.

We hope this review will help you better understand your requirements for wood stoves and make a home or a bathhouse cozy and comfortable.

The benefits of wood burning stoves for saunas

There are a number of indisputable advantages of wood stoves for saunas, you will understand more than once that you made the right choice, because:

- A sauna with such a heater can be built anywhere and heated at any time, as it works autonomously and is independent of power supply. Do not be afraid of possible interruptions in the supply of electricity - a stove on wood will not fail under any circumstances. This is especially true of suburban suburban areas where fuel can be found in any copulation.

- Fuel for a wood-burning stove is not a shortage and has an affordable price, even if it is decided to purchase high-quality firewood specifically designed for the bathhouse. Firewood for the sauna should be well dried out, only then you can get the desired effect of creating a healthy bath microclimate.

- A wood-heated stove warms up stones faster than an electric one

- Firewood when used in a bath is a safe and environmentally friendly fuel.

- Burnt and smoldering firewood retains heat in the stove for a long time, which means heat in the room, while the electric stove cools much faster, almost immediately after the power is cut off. The stove, heated by wood, remains warm until 12-14 hours, especially if it is folded from a regular brick, which also cools slowly and contributes to the internal conservation of heat.

Which oven is best to install in the sauna?

Before the owner of the sauna under construction, there is a problem when choosing a stove between:

Since each of them has its pros and cons. Another problem for many will be the storage of fuel, which should be stored for future use.

It is worth considering each option separately to determine all their pros and cons.

Steel furnace

The furnace made of steel sheet has an affordable cost, and this can be attributed to its positive side, and the fact that it quickly heats up, but also cools down quickly - this is its big minus. Such a furnace will have to be kept burning for the entire period of use of the sauna, and this will significantly increase fuel consumption. Saving on its acquisition, you will have to spend good money on firewood, so as a result, savings will not work.

Cast iron stove

A furnace made of this material is not recommended for installation in a sauna, as cast iron is a fragile material that is afraid of sudden changes in temperature. For example, if cold water gets on hot iron, cracks may appear in its walls and the furnace will become unsuitable for further operation. This factor is attributed to the main disadvantages of cast iron stoves and it is extremely rare to install them in saunas, although cast iron heats up quickly and keeps warm for a long time.

Brick oven

To heat a brick oven will require more time and fuel. Compared to the metal structure, this structure cools down for a long time, from ten to twelve hours. Therefore, a well-heated brick stove will give heat to the steam room for a long time, and you don’t have to worry that you will often have to throw firewood into the furnace.

But the construction of a brick furnace is not cheap, and in the absence of experience in this work will have to invite an experienced master stove-maker.

The sauna furnace has a special design, which is carried out according to a certain scheme, and for its laying it is necessary to choose the right heat-resistant solution, adhere to the rules that are defined for the thickness and processing of joints between bricks.

Metal furnace

Metal sauna stove with water tank

Cast iron and steel versions of wood-burning stoves for a bath have the same device, and their installation can be made in two ways, depending on their design:

- the firebox is located in the waiting room, and the heater is in the steam room,

- the furnace and heater are located in the bathhouse.

The first option is more preferable, since in the steam room you can accidentally burn yourself on the firebox door. Together with the heater, a water tank is also located in the steam room.

This diagram shows the design of a model of a sauna furnace, in which the furnace goes into the dressing room.

Construction of a wood-burning metal stove for a sauna

- This oven has a water dispenser. It is convenient in that you do not need to constantly add liquid to the heater - water or broth, it will gradually come in a predetermined amount. It is shown in the diagram at number one.

- At number two on the diagram is a heater closed by a water dispenser, which, when heated, will give a gift for a long time. Due to the fact that the metal furnace cools down quickly, a closed heater will be a good help for maintaining heat.

- A chimney pipe passes through the heater from the furnace. Its location also contributes to the retention of heat near the stones.

- On the other side of the pipe is the second part of the heater - already open. Water from the dispenser, passing through the closed chamber of the first heater and under the pipe, leaves the open heater in the form of dry steam.

- The deep and volume firebox made of heat-resistant steel has a chrome coating.

- A grate of cast iron is laid in the furnace, which cools for a long time, which means that it also retains heat from fuel.

- Under the firebox there is an ash pan chamber with a drawer. Waste from burning wood is collected there, and it must be cleaned after each heating of the stove.

- A remote channel comes out of the furnace, having a certain length, calculated on the thickness of the wall through which it will pass. This model is made to install it in such a way that the firebox door is in an adjacent room.

- A self-cooling door is installed on the furnace channel. It cools quickly due to the fact that it is located quite far from the combustion chamber.

- From the rear of the furnace, with which it goes into the steam room, passes the secondary air supply channel.

- On the front of the case, on the side that will be near the wall on the side of the steam room, a convector casing is installed, which helps the heated air to escape upward, and not into the wall.

- A chimney is put on the pipe that passes through the heater.

- A water tank is installed on the chimney, working on the principle of a samovar. The heated pipe inside it will serve as a good heat exchanger. The tank can be filled manually with water, or water can be connected to it.

Convenient tank for heating water

- Next, a chimney pipe riser is put on the tank pipe, which is carried out through the ceiling and roof. When passing through combustible floor materials, the chimney must be insulated with non-combustible materials. The thickness of the insulator should be more than the thickness of the ceiling by 7-10 centimeters and go towards the attic. Between the ceiling and the pipe, the distance should be 10-15 centimeters, filled with a non-combustible insulator. Sometimes for laying or filling the insulator arrange a box.

- Around the pipe head on the roof, waterproofing is necessarily arranged so that moisture can not penetrate the attic and does not damage the wooden elements of its structure.

To install a metal furnace, you need to properly prepare the place - it must be a non-combustible area made of brick, concrete or ceramic tile and a brick wall through which the combustion channel will pass.

An approximate diagram of the installation of a metal furnace in a sauna

The installation diagram of the furnace looks approximately as shown in the figure. Small adjustments are possible, for example, if the furnace is installed on a brick or concrete podium.

Brick sauna stove

A stove built of brick can be massive, or it can be neat and compact, it all depends on the area of the bathhouse. It can also be installed in two ways - a furnace in a dressing room or in a steam room.

Sauna with a brick furnace with a furnace in the dressing room

The stove itself can become part of the wall between two rooms. Looking at the diagrams of different designs of stoves and laying stones, you can choose the size and shape of the option that is suitable for a particular room of the sauna.

Possible design options

In addition to these models, there are furnaces with a built-in water tank, which is installed during the construction of the building. Its back wall is adjacent to the side wall of the furnace, and a piece of asbestos material is laid between them, which will save metal from burning.

Another option for mounting the tank may be to install it on top of the combustion chamber, but in this case, its bottom must be protected from burning with a single layer of brick or a cast-iron panel.

- A foundation is required for the installation of a brick furnace, and its construction begins with it. The foundation is arranged in a pit buried in the ground by 40-60 centimeters. It must be strengthened with the help of reinforcement. In size, it should be 10 - 15 centimeters larger than the base of the furnace.

- Further, if the furnace does not act as a wall, then the wall, built of wood, must be insulated with a sheet of asbestos or heat-resistant drywall.

Approximate layout of the furnace in the sauna

- A waterproofing sheet made of roofing material is laid out on the finished foundation.

- On top of the waterproofing, the laying of the furnace begins. It is produced according to an ordinary scheme, which will correspond to the selected model.

- When laying the walls of the stove, the evenness of the rows is controlled by the level, and the verticality by means of a plumb line. It is very important to observe the exact layout of each row and install additional elements (doors, grate, etc.) precisely on those rows and in those places that are indicated in the order.

- The doors, when installed, are fixed with steel wire, and sometimes temporarily supported by bricks, which are removed only after the door is well fixed with masonry. Strips of asbestos are laid between the masonry and the walls of the door, or it is wrapped with asbestos rope.

- The grate is also placed on strips of asbestos, it is no longer fixed by anything. It is heavy enough and will be located in a recess above the ash pan, so it will not move anywhere.

- The heater is displayed in the steam room, it is heated from the furnace, to which it adjoins the back wall. A chimney can be passed through it, which is then connected to a direct chimney.

- The passage of the pipe through the floors is organized in the same way as when installing a metal furnace.

In conclusion, I would like to say that the brickwork of the furnace should be made only of high-quality material and with the right heat-resistant solution.

A small video lecture with tips on choosing a sauna stove

For fire safety, you must strictly follow all the rules for laying and installing various elements, as well as pay special attention to the construction of a chimney. It should be noted that each step should be verified and thought out - this applies to the installation of any of the models of furnaces, since the safety of life of all family members depends on accuracy.

Do you like the article?

Save so as not to lose!

Closed Type

Such a unit is used for heating small baths. The metal case is vertically divided into three compartments. We list them from bottom to top:

- a chamber for loading fuel and blowing,

- a container for laying stones with a lid through the opening of which steam exits,

- a tank for heating water.

Red refractory brick, laid inside and outside the metal furnace, provides long-term heat storage in the steam room. A lidded container performs the same function with respect to hot stones. In this case, more humid steam is generated against the background of a rather low room temperature. With the design of a closed type, it is easy to create a regime typical of a real Russian bathhouse.

To warm up a closed type device, you must have a large fuel warehouse, as well as a lot of time to complete the steam heating process. However, upon reaching the goal, the furnace reciprocates: it will retain beneficial heat for a long time. Thus, a closed-type design is best suited for connoisseurs of a traditional Russian bathhouse with a birch broom.

Open design

The difference between this unit and the previous type is determined by the open heater, which is used as a grate for placing stones. This structural element is laid directly above the firebox.

The presence of masonry in the bath furnace with red refractory bricks is also considered a prerequisite. When the room is heated by such a device, drier steam comes out of the stone container, and the temperature of the surrounding area becomes quite high (≥ 100 ° C). Anyone who likes to get warm rather than steam will probably choose this type of heating device for his bath.

Combined Type Construction

In the name of the furnace lies the features of its structure. As a firebox, a tall box with double valves and grilles is used here. The presence of several pairs of such elements is necessary for the normal functioning of the blower and heater. Stones are stacked in the neck of the box from which the chimney comes out.

The difference between furnaces depending on the fuel used

The choice of one or another type of fuel determines the division of furnaces into several types. There are units that work from firewood, gas and electricity. There are also combined devices, for heating which two sources of thermal energy can be used: often this is gas and logs. Each such unit has certain advantages and disadvantages.

Wood stoves

Wood has long been considered the most affordable, relatively inexpensive and reliable source of energy. With the help of logs, the room is not only provided with heat, but also is filled with a unique fresh aroma. It does not require unnecessary costs for bringing to the furnace wiring or gas pipes. The unit, heated by wood, is especially appropriate in those regions where there is a complete absence or interruption in the supply of gas or electricity.

Nevertheless, installing in your bath a structure that works only from firewood, you should be prepared for the fact that such a device will heat up the steam room for a long time. In addition, the owner himself must take care of maintaining the required temperature and removing ash from the device.

The advantages of a wood-burning stove over similar units operating from other sources of thermal energy are manifested in the following qualities:

- fuel availability and cheapness,

- good heat dissipation

- wide selection of models

- the possibility of self-construction.

The disadvantages include:

- the need for systematic cleaning of the chimney,

- conducting constant monitoring of compliance with fire safety rules,

- the need for logging and equipment for their storage (we talked about how to make a fireman with your own hands earlier),

- the continuity of the process of planting firewood in the firebox.

Gas-fired sauna stoves

Mandatory structural elements of such a device are a gas thermostat and a fuse. These devices, located inside the housing, control the moment of extinguishment of the flame, followed by an immediate shutdown of the fuel supply. The economic factor is considered the main advantage of gas furnaces. This refers not only to the cost of blue fuel, but also the cost of installing equipment, as well as its maintenance.

The furnace installed in the bath provides quick heating of the steam room and is characterized by low fuel consumption. The only thing that can confuse the owner of the site is the need to connect to a common gas pipeline or the need to purchase and store cylinders with liquefied liquid fuel.

Gas stoves are very popular among Russians due to the following characteristics:

- Compact design due to the lack of an ashpit and a large firebox, like wood stoves. The small size of the device allows you to install the gas unit in a fairly compact steam room.

- The ability to adjust the optimum temperature achieved by setting the desired mode, providing a healthy microclimate in the steam room.

- No need for special care and utmost attention.

Rules for choosing a gas furnace

Each burner delivering fuel to the gas chamber is characterized by a special value of its consumption. This indicator determines the power and economic component of the selected unit. If you own a small bath, we recommend using a burner with a flow rate of up to 4.5 cubic meters.m / hour. This element can be installed in an existing oven. The main thing is to provide for an ideal match between the parameters of the threaded connections on the burner and the gas pipe.

When buying such a stove for a bath, it is important to ask the seller for all the necessary documents confirming the compliance of the device with the generally accepted quality and safety standard. If he does not have one, you should not even waste time on this procedure.

It is also necessary to avoid acquiring gas burners from an unknown manufacturer or without a technical passport. Devices that provide stable combustion of fuel, which are damaged or malfunctioned due to the end of their useful life, should also not be installed in their furnace.

Thus, the impeccable condition of the new burner, as well as the periodic routine inspection of this part of the device, are the key to a healthy stay in the bathhouse.

Combined ovens

Modern industry produces universal units that differ from standard designs in that they can be heated with natural or liquefied gas, as well as coal or wood. Such versatility of the furnace operation is provided by additional removable elements: gas burner equipment and devices for laying solid fuel. The device that supplies gas to the furnace includes gas burners, filters, shut-off and relief valves.

In order to be able to heat the bath with firewood, you need to stock up on a fuel receiver, which should be mounted in the furnace instead of the gas burner installation. Due to their versatility and relatively low cost, combined-type units attract the attention of domestic consumers.

Electric ovens

Many bath owners purchase devices that heat the room with electricity. The differences between such units are determined by the size, power indicators, operational characteristics and the heating period of the steam room. Such furnaces are compact, high thermal conductivity and durability.

Such devices are preferred because of the excellent opportunity provided by them to quickly and evenly warm the bath room. High power generated by the unit allows for a short time to create the optimal temperature regime in the steam room. The cost of electric stoves is available to many categories of people. Owners of saunas choose these devices mainly because of the lack of need for the installation of a chimney.

Such devices are preferred because of the excellent opportunity provided by them to quickly and evenly warm the bath room. High power generated by the unit allows for a short time to create the optimal temperature regime in the steam room. The cost of electric stoves is available to many categories of people. Owners of saunas choose these devices mainly because of the lack of need for the installation of a chimney.

Shape difference

Among the metal furnaces used for heating the bath, there are devices of various shapes. The market offers rectangular, curly and cylindrical models of a vertical or horizontal installation method.

The most acceptable option for uniform heating of all constituent elements is a rectangular oven. This is a fairly reliable and stably stable unit, which can not be said about the device of a cylindrical shape, which does not differ in constancy in heating the bottom and top of the structure. Such an imbalance will subsequently cause metal deformation.