The mix of the “Prospectors" brand "Concrete-contact" is a water-dispersion composition for priming, used in construction and repair work. The mortar helps to create a reliable, high-quality base on walls and ceilings for further work processes, for example, before plastering. The mixture also improves adhesion to smooth concrete substrates with poor adhesion and low moisture absorption.

Manufacturers of concrete mix "Concrete-contact" claim that the service life of the finished surfaces reaches 80 years.

Primer Composition

- quartz sand,

- styrene-acrylate dispersion, which is a binder component,

- cement,

- various fillers.

The water-dispersion primer “Concrete-contact” was created primarily to solve the problem of adhesion of concrete and gypsum mixtures, which when applied to an unprepared surface simply slide on a smooth base.

Flow calculator

| Is required | Amount |

|---|

Copolymer acrylic dispersion, sand, water, target additives, antiseptic.

- Internal work

- Concrete

- Tile coating, oil paint

- Walls

- The ceilings

- Gypsum plaster

- Tile (possible)

| Film color | cherry |

| Consumption | 0.2-0.3 kg / m2 |

| Drying time, not less | 2-3 hours |

| Mass fraction of latex, not less | 30% |

| Mass fraction of nonvolatile substances, not less | 55% |

| Temperature of air, base, materials at work | +5 to +30 ° C |

| Shelf life | 12 months |

Designed for pre-treatment of dense, smooth, poorly absorbing substrates (monolithic concrete, concrete blocks, slabs, etc.) indoors before applying gypsum plasters. It is used for priming surfaces covered with tiles or oil paint, before plastering or facing, as well as for the treatment of gypsum plaster before laying tiles. Not intended for subsequent application of cement plasters and for priming floor surfaces.

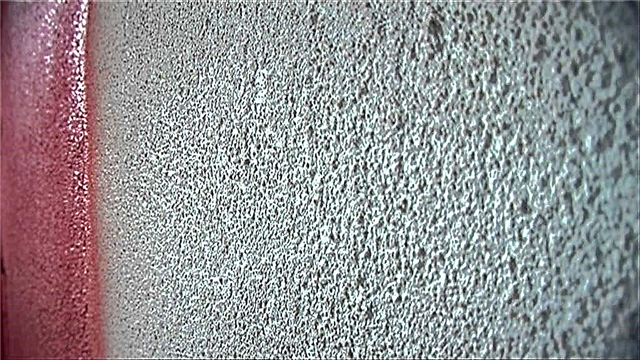

- creates a rough surface

- provides high adhesion

- interferes with sliding of plaster mix

- has good vapor permeability

- the presence of colored pigment facilitates application control

Specifications

The main qualities of the concrete-contact mixture:

- Quick drying.

- High adhesion of building materials to the base.

- Resistance to atmospheric climatic loads.

- Antiseptic effect.

- Good gas transmission.

- Waterproofing by forming a waterproof film on the treated surface.

Pros and cons to consider before choosing

Among the shortcomings only allocate a high price. Advantages of Concrete Contact:

- Ready for operation after opening the container.

- Fast drying of the applied primer, which allows you to perform the following processes 2-3 hours after applying the composition.

- Reliability of adhesion of the working surface to building materials.

- High wear resistance.

- Economical consumption.

- The white or pink pigment contained in the primer allows you to see the treated areas.

Where to apply?

"Concrete contact" is used when conducting indoor and outdoor work in rooms with any humidity. Water-dispersion composition processes such surfaces:

- cast concrete

- ceramic tile,

- concrete blocks

- drywall.

The composition is used to improve the adhesion of plaster or tile with poorly absorbing concrete walls and ceilings. The adhesive mixture is also applied on top of the old ceramic tiles before laying the new cladding or plastering the lined surface with gypsum plaster.

Mix “Concrete-contact” is not recommended by the manufacturer for processing surfaces directly in contact with food and water for drinking.

Consumption and use

The consumption of the concrete-contact mixture used is influenced by factors:

- fraction contained in quartz sand,

- application area,

- type of base

- application method.

It is necessary to choose a primer, taking into account the subsequent processes after its application. So, a mixture with sand of smaller fractions is suitable for thin-layer finishes, for example, for putty. A solution where coarse sand is appropriate when applying plaster in several layers, while the primer consumption increases by 1.5 times. On average, approximately 200-300 g of Concrete Contact are used per m2.

Preparatory work

Before using the mixture, the treated area is well inspected and prepared. Peeling secondary layers, grease stains, dirt, dust are removed from the base. The concrete-contact water-dispersion mixture is quite viscous, completely fills the pores of the base and practically does not penetrate the surface structure, therefore thorough cleaning is very important so that the primer does not exfoliate in the future. The primer is applied easily to a clean, dry surface.

To work with such material, you must first clean the selected surface from all that is superfluous.

To work with such material, you must first clean the selected surface from all that is superfluous.

Application

For a high-quality surface coating, the following requirements must be met:

- Stir the primer thoroughly before application.

- The temperature of the air and the base during priming should be between 5-25 ° C. At low temperatures, the primer will not protect the substrate from moisture and will not dry normally.

- For applying the solution, a roller or brush is used, since the consistency of the mixture is similar to paint.

- It is allowed to apply the soil with a spray gun.

- Do not skip when applying the primer to the surface.

- When priming in several layers, it is necessary to wait for the complete drying of the previous layer.

- Tools at the end of work are washed in water.

After drying, the primed surface should not be left without further finishing for a long time, as the settling dust and the ingress of various substances on the substrate will reduce the quality of adhesion. Work with the primer using protective clothing and personal protective equipment.

A little about the brand

The Prospectors company is known to many. For more than 25 years, it has been producing products of excellent quality in the domestic market of building materials. Brand products meet not only Russian but also European quality and safety criteria, in addition, they are made from completely safe raw materials. Production is automated, and each stage of product creation is fully controlled by specialists.

Every year, construction products of the brand "Prospectors" are improved by specialists in their field, both new and improved products are produced that meet the preferences of professionals and potential customers.

The assortment of "Prospectors" will please many, because in addition to high-quality concrete contact, you can also find paints, putties, universal mixes, grouts and much more that may be needed in construction.

Purpose and varieties

When preparing surfaces for further finishing, concrete contact is used due to its adhesive properties. Penetrating into the base material, it forms a rough layer, which can easily be covered with finishing materials. Another of its advantages is to absorb moisture that forms on concrete structures.

Unlike a conventional primer, the use of a concrete contact allows you to save yourself from such work as cleaning walls and ceilings from old paint or whitewashing. It can be applied directly to the paint, in any case, the adhesion of the base. It is a primer and also serves as a waterproofing layer. It can be applied under tiles in bathrooms, kitchens and saunas.

Certain types of this product are used for exterior decorating; it is frost-resistant. For street work, soil is used containing expanded clay or marble chips, as well as coarse quartz sand. This composition will hold the heavy facade plaster on concrete walls well. If it is coated on the outside with a concrete contact, it will be reliably protected from the weather.

Concrete contact can be of various applications, depending on the input components, particle sizes of silica sand. Concrete contact, which includes coarse sand, is often used to treat porous substrates.

Composition and characteristics

The primer concrete contact has the following composition of components:

- Portland cement or cement,

- Quartz sand,

- Acrylic polymer,

- Technological additives that ensure its vapor impermeability, hygroscopicity, protection against chemical and biological influences.

Concrete contact necessarily includes quartz sand with various grain sizes. For example, Ceresite primer contains a fine-grained mineral filler, it is used to treat smooth substrates.

The acrylic contained in the base of the concrete contact is a polymer adhesive, it provides adhesion to the base. In addition, dyes are added to the concrete contact. They help determine the thickness of the coating layer, visually detect unpainted spots.

Concrete contact has the following specifications:

- Environmentally friendly product. Does not emit an unpleasant odor, harmful fumes. Its use does not require additional protective equipment for the body and respiratory organs,

- Resistant to aggressive environments,

- Forms a waterproofing layer,

- It passes air, which eliminates the formation of mold, fungus,

- Drying time at 20 ° C and 70% humidity is 3 hours,

- Manufacturers set the term of its operation - 80 years,

- The recommended temperature for work in the room is from +5 to +30 ° C and humidity is 55-80%.

How long the concrete contact will dry depends on the temperature and humidity in the room. Under unsuitable conditions, additional heating can be used to speed up the process.

Instructions for use

Before you begin, prepare the foundation. The processing process includes the following actions:

- Rinse surface with dust or dirt,

- Remove aggressive formations: grease, bitumen, glue and others,

- To beat off poorly fitting plaster, remove peeling paint, remove lagging wallpaper.

Concrete contact primer requires application to a dust-free surface, this is the main condition for obtaining a solid prepared base for finishing. Water-washed structures should dry well before application.

If the walls were previously covered with chalk, they are washed with soap and water and dried. Lime whitewash is removed if it crumbles and exfoliates.

Choose the composition of the primer concrete contact, depending on the quality and condition of the treated surfaces.

Usually, the concrete contact primer is ready for use, you just need to mix the composition before work. Sometimes it is diluted with water as directed by the manufacturer. It is important to ensure that the mixture does not contain lumps.

The application of concrete contact is done with a paint tool - brushes, rollers, you can use a spray gun. Uneven concrete or brick walls are covered with a wide brush. This ensures the penetration of the concrete contact into cracks and joints.

For smooth surfaces it is better to use a roller. You need to try to apply stripes without leaving spaces between them. If the first layer has gaps, you need to apply the next to paint well. The subsequent layer is applied after the previous one has dried.

The primed coating dries after 3-12 hours. This time is indicated on the package, but you need to take into account the room temperature and humidity. To ensure that the soil is dry, you can slightly scratch it with a knife or spatula. Do not continue to work if the strength of the layer is not achieved.

Knauf

The concrete contact primer of this manufacturer is characterized by a finely divided composition based on fine quartz sand. It is used to cover smooth surfaces before finishing with plaster, lime, gypsum, tile adhesive, other finishing and decorative materials. Forms a rough surface.

Concrete Prospectors

It contains latex, which increases the strength of the base after processing. It covers surfaces poorly absorbing moisture. This is monolithic concrete, decrepit cracked tiles, other surfaces made of dense materials.

This species dries quickly (2 hours). When working with him, the productivity of construction work increases significantly. It is characterized by economical consumption - 200 g / m 2. Before use, shaking the contents of the jar is sufficient.

Ceresit

It has a water-dispersed component in the base, contains polymers and coloring pigments. Tightly covers smooth concrete surfaces before plastering. We get a vapor-and moisture-proof coating.

This soil can not be diluted with water, it is undesirable to use a roller when processing. It is applied only for internal works. It is non-toxic.

Axton

This is a dry mixture for priming. High-quality soil for construction and finishing works. Before use, just add the right amount of water, mix. The resulting mixture is ready for use.

Axton Concrete Contact is used for unpurified rough surfaces. The flow rate of the mixture is 300 g / m 2, dries within 3 hours.

So, we have identified what concrete contact is used for. The use of a universal and reliable primer greatly simplifies the construction process. This material provides high performance properties of structures, allows for a variety of finishes of external and internal surfaces.

Scope of use

To date, in the assortment of the company "Starateli" you can find a concrete contact primer to improve adhesion to smooth concrete surfaces. It can be purchased in the following volumes: 3 kg, 5 kg and 20 kg.

Concrete contact of this brand is suitable for various types of work.

- It is indispensable for preliminary construction work and surface treatment of different densities. Primers “Prospectors” can be coated with ordinary and monolithic concrete, concrete blocks, as well as ceramic tiles and drywall.

- The base can be not only dense, but also poorly absorb moisture, but concrete contact will cope even with the most difficult cases.

- Suitable for priming not only walls, but also ceilings.

- Despite the large scope, this concrete contact is not recommended for the treatment of surfaces that have direct contact with food products.

It is quite easy to apply and distribute the Prospectors primer. This can be done independently, without even resorting to the help of specialists. Since the mixture is ready for use, it just needs to be mixed thoroughly before application. You can distribute it with a roller or brush, as it will be more convenient for anyone. Do not apply to the frozen foundation. It is desirable to work in a room with a temperature regime of at least five degrees of heat.

Concrete contact "Prospectors" is available in special plastic buckets, in which it is very convenient to store and transport. Storage is recommended at temperatures between five and thirty degrees. When stored properly, this product can be used for up to a year from the date of manufacture.

Important points

Do not forget that before applying the concrete contact, the base must be dry, as well as pre-cleaned from dust and various contaminants.This mixture acts superficially; it does not penetrate the base structure itself. That is why it is very important to pre-prepare the base so that the primer does not detach further.

Work with the primer only according to the instructions., in addition, do not forget about overalls and other personal protective equipment, including gloves and respirators. Many people wonder how many primers can be made. According to experts, one or two will be quite enough.

Reviews

Most of the masters and customers who worked with this material leave extremely positive reviews about it and the brand. In general, it is noted that concrete contact is a very good choice for a variety of surfaces, even with a low level of adhesion. Due to the best quality of the material itself and its excellent technological properties, the coatings are obtained by ultra-strong. In addition, the craftsmen are pleased with the excellent consumption, technical specifications and reasonable prices for the material. According to many experts in their field, buckets with a primer mixture of 20 liters are considered the most popular, they do not need to be prepared beforehand, but you can immediately begin priming work.

For more details on the use of the primer, see the video.

Purpose and scope

Let's consider in more detail what the primer is for and where it is used:

- The primer composition plays the role of a link between the base and the applied finishing material. Even on a very smooth and slippery surface treated with this primer, anything will stick, since the quartz filler creates a roughness resembling sandpaper, which provides high-quality adhesion.

- Due to the penetration of substances into the structure of the base material, “Concrete-contact” makes its outer layer more durable.

- The composition is suitable for both porous absorbent surfaces and smooth, not able to absorb moisture.

- This primer is a solution to the problem of plastering monolithic concrete, on which gypsum plaster does not hold well due to poor moisture absorption.

Important information! Concrete Contact has one serious “contraindication”. It should never be used before plastering with cement mixes. The peel strength of the film created by this primer is 0.4 MPa, and the adhesion of any cement mortar starts from 0.5 MPa. In addition, the cement mixtures shrink and the applied layer of plaster is slightly stretched. If the solution was applied directly to the concrete, no problems would have arisen, with “Concrete Contact” it would lag behind the wall.

The name of the primer often gives the impression that it is used only for processing concrete slabs. In fact, "Concrete Contact" is universal, it is applied to almost any type of surface:

- on the brick

- solid concrete

- foam and aerated concrete,

- drywall, gypsum sheets, cement-bonded and tongue-and-groove plates,

- tile,

- bases leveled with cement or gypsum mixtures,

- surfaces coated with oil paint

- tree,

- metal.

If necessary, "Concrete-contact" can be applied even to plastic and glass.

Compositions from different manufacturers have some differences, so it is advisable to read the characteristics of the primer and its scope on the packaging before purchasing. So, for example, “Betocontact” from Knauf, according to the manufacturer, is intended for processing smooth, weakly absorbent or non-absorbent substrates, which include concrete, plastered surfaces, polystyrene foam, gypsum tongue-and-groove boards. It is applied under gypsum plaster, suitable only for interior use.

When buying, it is recommended to ask the seller for a certificate of compliance with established standards.

Technical specifications and application features

"Concrete contact" has the following properties:

- Drying speed. This primer dries very quickly. Depending on the surface area, the time of "readiness" is from 1 to 3 hours.

- Material consumption. The average value is 300 grams per 1m2. In fact, this indicator varies depending on the porosity of the surface and ranges from 150 to 500 grams per 1 m2.

- Moisture resistance. The coating has waterproofing properties due to the formation of a characteristic waterproof film.

- Life time. According to experts, the primer will not lose properties 70–80 years. However, this is only guaranteed if applied in compliance with the rules.

Features of handling the composition:

- The primer is applied at an air temperature from +5 to +30 degrees Celsius. The humidity should not exceed 80%.

- Despite the quick drying, the paint is applied only 12 hours after the primer treatment.

- Finishing material should be applied no later than one day, since dust reduces the adhesion properties.

- It is possible to dilute a primer with water.

- Packs of 3, 5, 6, 10, 14 and 20 kg are available for sale.

Concrete Contact is valued for not having an unpleasant odor. In addition, it is allowed to carry out processing indoors without the need for personal protective equipment.

Concrete Contact does not have its color. But in most cases, pink dye is added to it at the factory so that poorly processed areas can be seen when coating the surface. On sale, it is already in a condition suitable for use, which eliminates the need for kneading, applied by brush or roller. Following the example of manufacturers of other primers, some companies have launched a product in spray cans that spray material onto walls or ceilings.

Manufacturers produce "Concrete Contact" with different grain sizes, on which the purpose of the primer depends. The composition with a fine filler is suitable for subsequent application of putty, paint, with a larger one - under the plaster.

Application Features

Before applying "Concrete-contact", it is necessary to carry out preliminary surface treatment. To do this, you need to clean the wall or ceiling from dirt, wipe off the dust and scrape off the elements that will peel off.

After preparatory work, you can begin to apply the primer.

- First, a solution is prepared. It must be thoroughly mixed, since heavier particles (sand and cement) go down and they need to be balanced with the rest of the composition.

- When applying, use a brush or roller. The technical characteristics of the primer can be limited to just one layer. But if there is a need, for example, the wall is too uneven, you can apply the second.

The second layer of Concrete Contact is needed if the primer is completely absorbed, gaps are visible on the surface or the coating is easily removed by hand.

- While the material sets, you can begin preparations for further decoration.

Any primer dries for about 2-3 hours. In rare cases, time can be reduced to 60 minutes. To check the condition of the surface, you can draw along it with a metal spatula. If traces remain - the soil is not ready for further processing.

How much “concrete contact” is required depends on the type of surface.

- For porous substrates (concrete slabs, bricks), the soil consumption will be 300–500 g / m2.

- For surfaces with average porosity (monolithic concrete, bulk floors), the consumption will be 250–300 g / m2.

- For smooth substrates (reinforced concrete, tile, walls painted with oil paint) - 150–250 g / m2.

To reduce the consumption of Concrete-contact on porous substrates, it is possible to pre-soak the surface with a deep penetration primer.

The cost of the primer depends on its quality and the reputation of the manufacturer.

- The cheapest primer can be found from 30 rubles per kg. So, “Concrete Contact” of the Rainbow brand costs 25–45 rubles. per kg

- If you consider a not too famous brand, you will have to pay about 60–90 rubles. per kg This price category includes primers of the brands "Prospectors", "Founded", Pufas, "Bolars".

- When you purchase the most expensive material, the cost can be 100-160 rubles. per kg For example, the average price for Betocontact from Knauf in Moscow is 125 rubles. for 1 kg. At the same time, high-quality soil of the famous Ceresit brand is cheaper - 70 rubles. for 1 kg.

You need to choose according to your financial capabilities and how many square meters you plan to process. When all the rooms of the apartment are to be finished, then you can use a primer of the middle price category. If water-repellent properties and durability are important, then it is worth paying attention to more expensive and high-quality products.

You can clearly see where and how "Concrete Contact" is applied by watching the video.