These are building mixtures based on mineral or polymer, which are used to align walls and ceilings, eliminate defects in repaired surfaces, and also to decorate rooms. Leveling plaster mixes and putties are usually white or gray. Decorative coatings can already be painted in the desired color, have various fractions of fillers in their composition to create a relief surface or imitate natural stone. Ready to apply, they are a plastic mass. What is the difference between plaster and putty, we will consider below.

These are building mixtures based on mineral or polymer, which are used to align walls and ceilings, eliminate defects in repaired surfaces, and also to decorate rooms. Leveling plaster mixes and putties are usually white or gray. Decorative coatings can already be painted in the desired color, have various fractions of fillers in their composition to create a relief surface or imitate natural stone. Ready to apply, they are a plastic mass. What is the difference between plaster and putty, we will consider below.

What is the difference between the composition

Stucco consists of binder, filler, water and polymer additives. The basis may be cement, gypsum, lime or clay. Their combinations are possible, for example, lime-cement, lime-gypsum mixture.

The ratio of dry weight to soda varies based on the purpose of use. If plastering is performed in 3 layers, then each of them is prepared with a different consistency. The first layer - the spray is kneaded with a low binder content, the primer layer - with an average content, and the final finish - with the maximum amount of adhesive. That is why the latter is obtained as dense and durable. For plastering in 1 layer, it is necessary to use average values.

Cement plaster is very durable due to the presence of sand, and also has high resistance to various external factors. The gypsum plaster mixture does not have sand in the composition, it is less durable, but more plastic, the plastered walls are not so rough.

Putty based there may be the same astringents mixed with fillers (chalk, talc, barite, etc.). At the same time, it can be starting and finishing, the difference between them in the grain size of the binder material. Putties are also made on a polymer basis: acrylic and latex, they have a marble filler in their composition, which gives the material a pure white color. With their help, they make finishing puttying of the walls, creating perfectly even and smooth surfaces, for example, for further painting.

Putty based there may be the same astringents mixed with fillers (chalk, talc, barite, etc.). At the same time, it can be starting and finishing, the difference between them in the grain size of the binder material. Putties are also made on a polymer basis: acrylic and latex, they have a marble filler in their composition, which gives the material a pure white color. With their help, they make finishing puttying of the walls, creating perfectly even and smooth surfaces, for example, for further painting.

Putties are sold as well as ready-made plasters (in buckets) or as dry mixes (in bags), which usually consist of gypsum or cement with additives. Before use, they must be diluted with clean cold water.

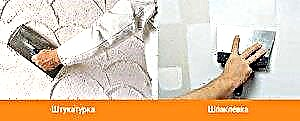

So, what is the difference between putty and stucco? They may differ in composition, but the whole point is that the putty walls are smoother than the plastered ones. Due to the finer fraction in the composition, the smaller the size of the putty grain, they create a surface without the roughness inherent in plaster. These features determine what is used first for wall decoration.

Areas of use

Consider what these two building materials are for.

Plaster is used for:

Plaster is used for:

- Alignment of large curvatures of the walls.

- Elimination of potholes, cracks and other major defects on the walls.

- As an intermediate (supporting) layer before finishing. For example, even even walls made of aerated concrete are pre-plastered before wallpapering or tiling.

- For heat and sound insulation, protection against moisture, fire and even radiation.

- As an independent finish of facades and interior walls.

As you can see, plastering is a rather universal wall covering, it is used both inside the house and outside, for residential and working buildings, utility rooms and garages.

Putty can also be used for indoor and outdoor use.:

- Puttying plastered walls before wallpapering, painting.

- Hiding the joints of drywall, hats of screws.

- Elimination of minor defects, holes, cracks and pits.

- Repair of plaster, chips and scratches of the decorative coating.

We have already noted above what the difference between a plastered and a putty wall is their smoothness. When you want to create the perfect surface, it is better to putty on top of the plaster and walk with a soft grater. When you can do without putty when decorating the walls will be discussed below.

When can you not putty?

If we want to glue the wallpaper or paint the walls, we must always apply putty for the best leveling of the surface. Even if the finish will be carried out on gypsum boards, you still need to putty the entire surface in at least one layer. This is necessary so that thin or light wallpapers do not shine, and the paint lies evenly and does not show any flaws.

If we want to glue the wallpaper or paint the walls, we must always apply putty for the best leveling of the surface. Even if the finish will be carried out on gypsum boards, you still need to putty the entire surface in at least one layer. This is necessary so that thin or light wallpapers do not shine, and the paint lies evenly and does not show any flaws.

But there are times when it is not necessary to putty.

- If you have even concrete walls with a uniform color, and the wallpaper is used dense or embossed, then it is quite possible to not putty the wall before sticking it.

- It is also not advisable to use putty if you are doing decorative plastering on the walls.

- Do not putty the walls before they are finished with ceramic tiles.

- In technical and utility rooms where minimal finishing is required, you can paint the walls directly on the plaster without putty.

- Often brick or aerated concrete masonry is painted without any preliminary preparation at all - if this is not necessary, or it is a design decision.

Gloss. Experienced craftsmen use plaster when plastering with a plaster or cement mixture. This technique may well replace further puttying, which means that significant savings in funds and effort for repairs come out.

Gloss. Experienced craftsmen use plaster when plastering with a plaster or cement mixture. This technique may well replace further puttying, which means that significant savings in funds and effort for repairs come out.

Glossing is carried out using a soft grinding block. A stuck plaster layer, but not yet dried, is abundantly wetted with water, and then rubbed in a circular motion. Then, along the treated wall, they are carried out horizontally and vertically with a wide spatula, removing all dust and particles of plaster. After such preparation, you can paint or glue the wallpaper without finishing putty.

Difference in use

Now consider the difference between the technical characteristics of the building materials we are considering.

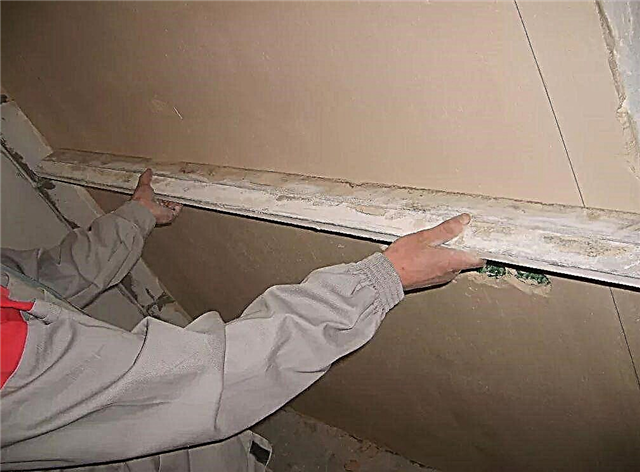

Wall plastering for their alignment it will require such tools: narrow and wide spatulas, trowel, long construction rule, grater, grater. The plaster is applied in several layers.

- The first layer is sprayed - liquid grout is used. The thickness is usually 4-5 mm. The spray is done on the brick walls, it must penetrate the pores and seams of the brickwork, ensuring reliable adhesion to subsequent coatings.

- The next layer is a primer. It is laid 5-7 mm thick, depending on the solution. Also, the soil can be applied, if necessary, not in one, but in two or three layers. In this case, each time you need to wait until the wall dries.

- The last layer - a coating - is applied with a thickness of not more than 2 mm.

The drying time of the plaster depends on its type, the type of surface on which it is applied (concrete, wood or drywall), the humidity of this base, air temperature, and also the thickness of the layer.

The drying time of the plaster depends on its type, the type of surface on which it is applied (concrete, wood or drywall), the humidity of this base, air temperature, and also the thickness of the layer.

It usually takes 3-5 days for the plaster to completely dry with a layer of 1 cm.

To speed up the drying process, hairdryers or lamps are not recommended. Direct exposure to heat on the wall will lead to uneven and unnatural drying of the mixture, the finish may crack. To speed up drying, you can ventilate the room, turn on warm floors or a heater in the center of the room.

Puttying the walls It is carried out in two stages, which include applying the start and finish mixture. You will need such tools: a narrow and wide spatula, an angled spatula, an abrasive mesh and a jointer for grinding.

To align the wall, you must first repair the defects - pits, seams, joints. After this, a layer of starting putty is applied to the entire surface. Thickness up to 5 mm.

To align the wall, you must first repair the defects - pits, seams, joints. After this, a layer of starting putty is applied to the entire surface. Thickness up to 5 mm.

The finishing layer is applied with a thickness of 0.2 - 2 mm, its main goal is to prepare the surface for subsequent painting or gluing, perfectly leveling the surface.

Drying time for different types of putty may vary. For example, the superfine polymer mix Prospectors dries in 4 hours at a thickness of 2 mm.

So, we examined what plaster and putty are. They differ not only in the thickness of the applied layer and drying time, but, and most importantly, in the smoothness of the created surface. Remember that it’s very simple at first: smoothing walls and large defects - using plastering, eliminating unevenness in small volumes and roughness of walls - using putty.

We hope that the article was useful to you, leave your comments and questions in the comments below.

Material difference

People usually start to wonder if what is the difference between putty and plaster when there is a need to level the walls. As a rule, they have already consulted with specialists, and they have issued a verdict: it is necessary to plaster. And before you imagine long overweight women in shawls and dirty robes imagining how to putty differ from stucco in the imagination.

The word "putty" can also be written as "putty" - there is no clear-cut rule in this regard in the Russian language, this word is foreign. It is also not worth focusing on the word “putty knife” - either with doubts about the spelling or with the classification of finishing processes. There are many things you can do with a spatula - for example, to remove wallpaper from a wall.

Plastering work

Otherwise, this process is called roughing. The purpose of this process is to geometrically align the surface. When plastering external walls, there is another goal - to create an additional insulating layer, albeit a small one, especially when porous aggregates such as pumice, perlite, etc. are present in the solution.

Otherwise, this process is called roughing. The purpose of this process is to geometrically align the surface. When plastering external walls, there is another goal - to create an additional insulating layer, albeit a small one, especially when porous aggregates such as pumice, perlite, etc. are present in the solution.

The plaster layer must have some strength, therefore, it contains both a binder and aggregate - moreover, its fraction is smaller than that of masonry mortars, but more than that of finishing solutions. Among the stucco solutions are distinguished:

- cement

- cement-lime,

- calcareous

- gypsum.

There are also lime-clay solutions, but they are not used in the interior decoration of residential premises. A solution is called a binder in it - that is, cement, lime and gypsum, respectively.

The first three types of solutions can be prepared centrally, but can also be prepared on the spot - it all depends on the volumes. Lime mixes can be prepared morethan a day ahead, they do not lose their viability for a long time. Gypsum mixtures are sold dry and are kneaded in place. Now nobody uses pure gypsum: it quickly sets, within 10 minutes. In finished mixtures, in addition to gypsum, there is a fine aggregate and an inhibitor that slows down the setting process.

The main difference between plasters and putties is the granularity of the first. The sand in their composition can be felt with your hands and it will be visible and palpable on the finished surface, no matter how it is stroked. Because of this, the plastered wall cannot serve as a good base for painting or wallpapering - their consumption will be high simply due to the increased surface area, and the pores that are in the plaster layer will absorb glue or paint inside.

The main difference between plasters and putties is the granularity of the first. The sand in their composition can be felt with your hands and it will be visible and palpable on the finished surface, no matter how it is stroked. Because of this, the plastered wall cannot serve as a good base for painting or wallpapering - their consumption will be high simply due to the increased surface area, and the pores that are in the plaster layer will absorb glue or paint inside.

Walls with large blockages can be leveled with plaster. Sometimes they write that the total layer should not exceed 5 centimeters. In fact, there are cases when a wall straightened by builders is smoothed by 15 cm - to prevent cracks, the plaster is simply reinforced with a mesh.

The plaster is applied in three layers, but with completely curved walls, you can apply all seven, most importantly, in one day do not align morethan by 1–2 centimeters (can slide down). To do this with putty is simply to throw out the money.

High-quality plaster (this is not the quality of the mortar, but the quality of the final work) is done using beacons - pre-installed temporary supports that serve as limiters. The solution is sprayed with a hose or trowel, gypsum solutions are applied with a small spatula.

Sometimes the third layer - a covering - is produced by another solution. So, spray and soil (the first two layers) can be cement or lime, and the covering is gypsum. It is already produced with a wider spatula.

Putty and its purpose

In construction companies, plasterers are not involved in puttying, but painters - then they should cover it with top coatings. This process is part of the finishing process.

In construction companies, plasterers are not involved in puttying, but painters - then they should cover it with top coatings. This process is part of the finishing process.

Purpose of putty - make the surface smooth and uniform. The wallpaper will stick well to it, the painted, puttied walls will look noble. There will be no cost overrun of materials, which in our time is very important, given the rising prices for them.

Putty is a very large class of goods in its composition. They can be:

- oily

- oil-glue,

- gypsum

- polymer

- epoxy

- polymer

- glue.

And this is far from all - for example, at some woodworking enterprises, putty formulations themselves are made from ocher, drying oil, wood dust and clay. Each putty has its own properties, and not every one of them can be putty all, for each type there are both preferences and limitations.

These materials are fine-grained. Moreover, when working with them, you should carefully monitor that trash does not get under the spatula: this will ruin both the process and the result. Some types of putty are sold ready-made, others need to be bred on the spot. Some give a solid surface, others require a reinforcing soil (if the composition contains gypsum and chalk).

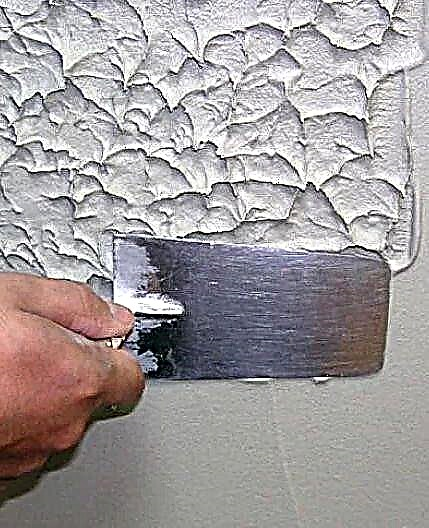

Puttying of surfaces is done with a wide spatula. Finally, the wall can be sanded - which can not be done with stucco.

Features of choice

Having figured out how plaster differs from putty, you can decide what kind of work you need. To do this, simply check your wall with the usual building level. If the blockage is more than one centimeter - align with plaster, and then go through puttying. If you don’t care whether the wall is curved or not, the main thing is to be smooth - putty.

There are times when you will not care what to apply, plaster or putty. This happens with small volumes, for example:

you need to cover the hole in the wall after pulling out the nail,

you need to cover the hole in the wall after pulling out the nail,- close up the place where a piece of old plaster fell off, if you don’t plan to make repairs in the near future - a thick oil putty is perfect for this purpose,

- to cover the knot from the wooden surface,

- Cosmetically mask a crack in the ceiling or wall.

Here you can use both gypsum plaster and putty. If the first ironed with a wet spatula, then traces of such a minor repair will not be visible.

Plastic plasterblocks can be placed on the gypsum dry mix - this is the most convenient and cheapest way to fix them. Putty can not do it. Lime plaster can not be replaced with anything if you want to make a natural mural on the wall.

That's all the differences between these materials and types of work. If you want to know more, master both processes. Such skills will always come in handy.

Putty and plaster - the definition of how they differ

To begin with, it should be noted that plaster is a unique mortar for construction, with the help of which it is possible to carry out the alignment process of internal as well as external walls, ceilings.

Putty will be ideal for leveling surfaces only when the amount of work is quite small. In other words, with the help of putty it is possible to smooth out confidently small defects - cracks, seams and more.

From a practical point of view, we note the following points:

- the cost of plaster, when taking into account the amount of work, is lower. The fact is that the filler material is quite large, so its cost against this background is much lower,

- due to its filling, plaster is considered a durable material,

- plaster can be laid in a thick layer.

What is the basis of the mixture

To begin, consider the plaster, which is based on cement, as well as sand and various polymer additives.

With the help of cement, sand and polymer additives, the material becomes as plastic as possible, which helps to better adhere to the main material.

With the independent preparation of such a mixture, experts recommend adding PVA glue. Very rarely use compositions with lime components, as well as clay. It is difficult to purchase such solutions, because they, as a rule, can be made independently.

What is the composition of putty?

Often used is the option of mixing cement, sand, as well as plasticizer. The difference with the plaster is that in this case the grain size of the mixture is much smaller.

Cement types of putties are used in the decoration of external as well as internal walls.

They are characterized by high water resistance, which allows them to be used on different types of paintings.

Plaster types are considered a finishing material that is intended solely for indoor use.

When working with gypsum mixture, it is advisable to know its flow rate. At present, Rothband is very much in demand. In this case, the main difference from the plaster is that the grinding of gypsum is very small, so it can serve not only as a bonding element, but also as a filler.

There are high-quality types of mixtures based on acrylic resins, which include such resins, as well as chalk, which serves as an independent filler. Also, among the components of this material there is water.

Acrylic mixtures are used for rooms, regardless of whether they are outside or inside the object.

There are other composition options that can rarely be found on sale, but, nevertheless, they exist:

- oil putty is created on the basis of natural drying oil,

- epoxy version is made with epoxy resin,

- the glue type contains not only drying oils, but also about 10% of the glue,

- a mixture based on polyvinyl acetate glue, as well as a mineral filler,

- latex is characterized by a binding component - latex.

Putty and plaster - is there a difference in application

To accurately determine the plastering process or possible putty, you just need to know the subtleties of the use of such materials.

If the wall that needs to be fixed has certain blockages, it is worth leveling them with plaster, in case the defects are very small, they should be puttied.

For more information about plastering and puttying walls, see the video:

Usually, after applying the plaster to level the blockage, then you have to use putty. In order to understand what exactly needs to be used first, one or the other option, it is important to understand that after complex alignment, any canvas needs to be made suitable for painting as well as wallpapering.

Drawing on the wall for interior decoration of the room - how to perform work

How to do the finishing work? First of all, cement plaster has certain subtleties of the laying process, as a result of which:

- the wall is pre-moistened,

- the desired portion of the solution with a trowel is thrown on the wall,

- the mortar that remains on the wall should be leveled with a trowel.

This is the simplest and most common plaster technology. When carrying out facade plastering on external walls, first spray, apply a deep penetration primer, and then apply a coating or paint. The last layer is recommended to be smeared.

Gypsum mixture, putty or plaster, also applied by spreading. Application steps:

- with a narrow spatula, the mixture is superimposed on the middle layer,

- material is applied to the entire surface evenly, after which it is distributed in the same width over the canvas. The thickness depends on what kind of material is used, as well as on the purpose.

Make sure that the thickness of the layer is not more than one centimeter. The maximum permitted thickness is 5 centimeters. If there are many uneven areas, it is recommended to additionally apply a suspended ceiling or false wall.

More and more people, in order to survive the winter heating season comfortably, use foam foam as one of the varieties of polystyrene as a heater for their home. Here everything is about preparing the walls and the method of application.

Wall panels for the bathroom are quite easy to install, they are durable, cope with temperature extremes, last a long time, and if necessary, they can be easily removed. By following the link, get acquainted with the features of selection and installation.

Dry screed is a special layer of a mixture of sand - cement, with the help of which they make a good base for the floor. Dry floor screed - high quality, fast and cheap.

If the thickness of the plaster is up to three centimeters, you can not use reinforcement.

In those situations where the thickness is more than 3 centimeters - it is imperative to reinforce using a fiberglass or steel mesh.

Depending on the thickness of the plaster, the drying time depends on it. Before you start puttying, it is necessary to prime the surface. If you compare the two above materials, then the putty does not provide as strong adhesion as plaster.

Before painting the walls again it is worth carrying out a priming.

With the help of such actions, the surface will become much stronger, and its porosity will become less, which affects the full consumption of the paint material. In addition, these actions will improve traction with a clean coating.

Differences between plaster and putty

When summarizing the main results, it is necessary to note the most important differences that exist between materials such as putty, as well as plaster:

- we will reliably attribute the plaster to building mixtures, which differ in large grains in the composition. Hard putty is considered fine-grained material.,

- plaster has a specific purpose - it evens out any irregularities in the amount of up to five centimeters. Putty is used in the same process, but in the case when there are very few irregularities or they are insignificant,

- for example, it can be easily used during cosmetic repairs, the size of the irregularities of which is up to one and a half centimeters,

- the plaster is in a number of intermediate leveling layers, and the putty is distinguished by one of the main layers, which is laid in front of the finish,

- the wall after the plastering process is “afraid” of rubbing with an abrasive sanding, and it is not at all scary to putty,

- plaster tends to dry for a long periodfor several days. Filling dries up already within one day.

As you can see, the differences between these options for materials are not significant, but they exist. From the above information, you can also find out how gypsum plaster differs from putty. These are quite important data, since the quality of the construction activities carried out depends on them.

Moreover, the choice between materials depends on what should be done, as well as other factors, including material properties.

Do not use mixtures for interior decoration when decorating exterior walls.

It does not threaten anything terrible, with the exception of the money spent, as well as time. Moreover, we must not forget that each of these materials is also distinguished by its manufacturer.

It is worth choosing a reliable and trusted manufacturer that produces really high-quality materials, so that after performing all the repair operations you really enjoy and enjoy the result.

When choosing a mixture, do not forget that this or that mixture has properties, characteristics and subtleties during use. This is important data that affects the entire process. If it is impossible to independently carry out the process of work, it is recommended to contact professionals in their field. We also recommend that you read the material about latex putty.

What is plaster?

Plaster allows to repair cracks and basic wall defects. This is a layer formed by hardened mortar.

| Title | Description |

|---|---|

| Cement | Universal in application, inexpensive in price. It does not differ in durability, freezes for a long time, |

| Gypsum plaster | Durable, dries quickly. Hydrophobic, which significantly reduces the number of rooms in which it is used, |

| Lime | It has moisture resistant qualities and lasts a long time. It does not freeze quickly, for a quick repair it will become a problem. |

Each of these compounds is mixed with each other in the indicated proportions, contains dyes and antiseptics (the addition of plasticizers is allowed).

Work with walls

Work with walls

Decorative plaster for interior decoration does not need additional cladding.

Wall alignment

Some tips for leveling walls:

- Calculate the wall level (using a stretched thread). Small irregularities do not require the installation of beacons.

- Initially, plaster exclusively problem areas, then pull the mass with a spatula. A putty is put on the wall.

- The wall is cleaned with sandpaper.

Wall alignment

Wall alignmentRestoration and decoration

In continuation of the topic, what is the difference between stucco and putty, we will analyze restoration and decorative wall decoration. The most significant and obvious cause of defects is the initially incorrect application of plaster on the wall. If finishing work was carried out in hot, dry weather, and the surface was not wetted, be sure to wait for small cracks throughout the area. For this, restoration is carried out using decorative finishes.

Decorative wall decoration

Decorative wall decoration

Repair with decorative plaster consists in closing up cracks and chips with a fresh solution. Stick to the following rules, otherwise chips and breaks will soon appear again:

- Pick up a crack (it is allowed to remove unspoiled material).

- Knock down exfoliated areas, scrub off all the plaster for better adhesion to the wall of the new layer. Finishing does not go astray - moisten it with warm water.

- Apply decorative plaster with a spatula from top to bottom and rub it. If the mixture has not been tinted, go for an additional sandpaper. Give the site a rectangular shape - subsequently it will be less noticeable. Insert reinforced tape into the crack for strength.

What is putty?

What is plaster and putty, what is the difference between them? Putty is a viscous mass formed with the help of dry matter (powder) when interacting with water. Finishing works on cladding and leveling are not performed without putty, because without it it is difficult to make the walls smooth. It is used to prepare the site for painting and cladding, for wallpapering.

Putty walls

Putty walls

There are many types of putty, because they serve different purposes. In most cases, we are talking about differences in the compositions. The following types are distinguished:

| Photo | Title | Description |

|---|---|---|

| Gypsum | Affordable, easy to use. Of the positive properties, the absence of shrinkage is distinguished. Disadvantage: poor moisture resistance. For wet rooms not recommended, |

| Cement | Moisture-resistant, has a significant degree of shrinkage. It is applied in bathrooms and corridors. |

| Acrylic (polymer) | Putty is insensitive to moisture, it has no shrinkage. Applies to any surface. |

For different bases, different types of putties are intended. If the surface is gypsum, use gypsum putty.

For start leveling use putty mixes. Finishing putties will help in decorating the cover with patterns and figures. To create elaborate elements on the walls, universal putty is usually used.

What is the difference between putty and plaster or what first?

Initially plaster the wall in three steps.

- Spray - Using a broom, the grout is applied to the wall, where cement will later be applied.

- Primer - a denser leveling layer, performed with a trowel.

- Nakryvka - carried out using a spatula.

Putty on plaster is the final stage, which allows to achieve a good result and sufficient smoothness.

Puttying on putty is not forbidden, but it is not advisable to carry out a similar procedure. There is nothing to translate expensive material to cover cheap.

Putty and plaster are not interchangeable mixtures, but they complement each other. If you want to create a perfectly smooth base for finishing, use putty. Use plaster only for preliminary leveling of surfaces.

Do I need to prime the walls before puttying?

The answer to the question of whether to primer the walls before puttying follows from the fact - the walls will still have to be primed before applying the finish coating. Spending once again on the primer is completely useless.

The primer before putty has a number of advantages:

- When applied, the primer fills all pores and cracks in the wall. This creates a continuous film, helps adhesion (adhesion). We recommend applying plaster in two layers (the first layer is absorbed into the surface of the wall itself).

- The primer penetrates the surface of the wall, strengthening it. Take a deep penetration primer - the effect will be stronger.

- Using a primer you will save significantly - it reduces the consumption of finishing material.

Plaster and putty - what is the difference or how to clean the walls correctly?

To clean the walls, start by looking for cracks and chips. If there are not many defects, clean these places and cover with a primer. If there are many defects, you will have to remove the entire layer.

In the process of repair

In the process of repair

Before you do this, prepare a room - take out the furniture or pack it in polyethylene. Lay out newspapers or film around the perimeter of the floor, seal the space between the doors and walls with paper tape. Hang a wet sheet on the door. It is advisable to get a respirator and special glasses.

Do not hammer with a spatula - completely cover so you do not clean. Moisten the surface with water using a spray bottle, wait a few minutes, and then proceed. If it does not come out after that, use a starch solution. To prepare it you will need:

- 2 tablespoons of starch,

- liter of water.

Wall wetting

Wall wettingThe composition is mixed and poured into a spray bottle. The mixture splashes onto the wall. After 20 minutes, when the product penetrates deeper into the structure, chip the coating with a spatula.

For greater effect, apply starch not with a spray bottle, but with a rag or sponge.

All about the difference between putty and plaster

Perfectly leveled surfaces are an indicator of the high quality of construction work. Unfortunately, in practice this is extremely rare. Therefore, before finishing the walls, it is most often necessary to level them using special mixtures.For the first time faced with such a problem, few can immediately find out in the variety of the assortment of building stores. We will figure out what is the difference between stucco and putty, and where each of them is used.

Cement and sand

Very strong and durable mixture. Used correctly for decades. It is insensitive to moisture and temperature changes.

A mixture of cement and sand can level out significant irregularities. Differs in low cost. If necessary, you can make it yourself. Of the disadvantages you need to know about the significant weight and low ductility of the material.

Plasticizers are introduced into its composition, but this does not completely solve the problem. Cement and sand mass is quite difficult to lay. It dries for a very long time, so the work stretches for a long period.

Plaster differs in the size of the filler included in its composition. Usually it is quartz sand. The larger it is, the greater the irregularities can close the solution. But at the same time, the roughness of the finished coating also increases. Therefore, the use of plaster for the final leveling is impossible. Her task is to prepare the basis for this procedure.

What is the difference between plaster and putty

Despite some similar compositions, the materials are completely different. The main difference is the size of the filler grain. Let us explain why this is so important. The grain diameter determines the maximum thickness of the layer that can be laid. The larger it is, the correspondingly thicker the layer. Therefore, a plaster mass with a large filler can even out deviations from the plane, and draw out significant irregularities.

Fine grain putty paste is not capable of this. But with its help you can get a perfectly flat surface, without the slightest bulges and pits. The main difference between the mixtures determines the remaining differences.

- The strength of the plaster mixes, ceteris paribus, is significantly higher. This is easily explained: large granules, which act as their filler, are more difficult to budge than small ones.

- Shrinkage is much less or even absent with puttying agents, so they are less prone to cracking or peeling. Provided that the technology of their application is not violated.

In addition, the cost of stucco is always lower than putty.

Differences in application methods

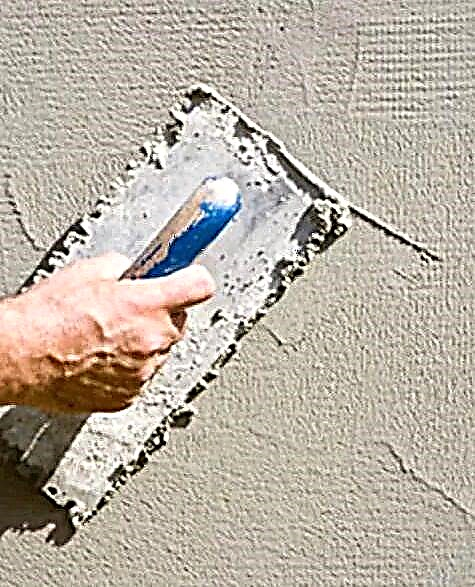

Significantly different methods of applying the compositions. Let's start with the plaster. It is laid in this way.

- The base is freed from the remnants of the old lining, cleaned and primed.

- Using a trowel, the solution is thrown onto the wall with some effort. So it sticks better.

- As a rule, if work is carried out on lighthouses, or by a half-ton the mass is distributed along the wall.

If the surface curvature is very large, at least three layers of mortar are applied in stages. This is done like this.

- Spray The thickness is 3-5 mm.

- Priming. Base layer. It can be applied at one time or in stages. The thickness of one layer should not exceed 5-6 mm. To strengthen the finish, reinforcement with a special mesh is necessarily used.

- Nakryvka. Finishing layer no more than 3 mm thick. For it, fine-grained paste is used.

This is how they work with non-ductile cement. Gypsum mixtures are imposed as if smearing on the wall, since they are more elastic. You can plaster and machine. This greatly improves productivity. In this case, the mass is supplied to the base under pressure, which provides better adhesion. But manual alignment is still present, look at the video.

For puttying, other methods are used, taking into account that the layer should be much thinner. A small amount of paste is drawn onto the tool, then evenly distributed over the plane.

Application area

An important difference between plaster and putty is in the field of their use. Plaster material is selected to correct a significant curvature of the surfaces and their deviations from the plane. It is possible to correct differences of the order of 50 mm. In order for the work to be performed efficiently, the basic requirements should be observed.

- If it is necessary to correct a significant difference, several layers of the mixture are superimposed. Each of them should not be higher than 7 mm.

- For formations with a height of more than 30 mm, reinforcement is necessary, otherwise peeling is inevitable.

- If there are differences of more than 50 mm, perhaps the best option would be alignment with drywall or installing a suspended ceiling.

Putty is used to obtain a perfectly smooth surface. The maximum differences in height that can be leveled with its help are 15 mm. Thicker layers are prone to shrinkage and delamination.

Work sequence

After getting acquainted with the main characteristics and differences of the mixtures, it becomes clear that they are used in different cases. But often stacked alternately. We will analyze what is first: plaster or putty.

- For surfaces with cracks, potholes, drops of 50 mm or more, the sequence of actions will be as follows: cleaning, priming, single or multi-layer plastering, priming and puttying.

- For bases with the correct plane and minor defects, a different algorithm of work is used: cleaning, applying the soil, laying the starting putty mortar, priming, applying the finishing composition.

- If the surface is flat, without noticeable defects, it must be puttied with a finishing paste. This is quite enough to give the desired smoothness.

Despite the significant difference between the two materials, certain skills will be required to work with them. If you plan to self-apply the mixtures, it is best to first practice on subtle fragments,

This should be done in good lighting, and considering the result, it is worth changing the direction of the light flux. So previously imperceptible flaws become visible.

you need to cover the hole in the wall after pulling out the nail,

you need to cover the hole in the wall after pulling out the nail,