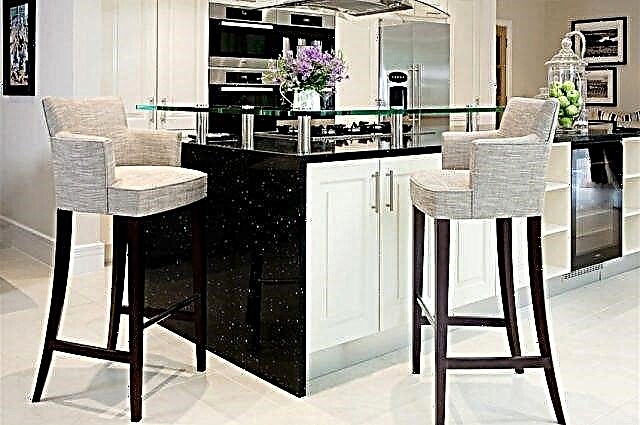

Not every apartment has spacious kitchens. But if you were lucky enough to live in a large apartment, and the kitchen is of considerable size, then it can be divided by a bar counter. This interior item should be comfortable and multifunctional. It is an indispensable attribute in kitchen studios, which in our time are at the peak of fashion. They combine a kitchen, a bar and a living room. This visually enlarges the room, and the living space is used wisely. They also make such racks in private homes.

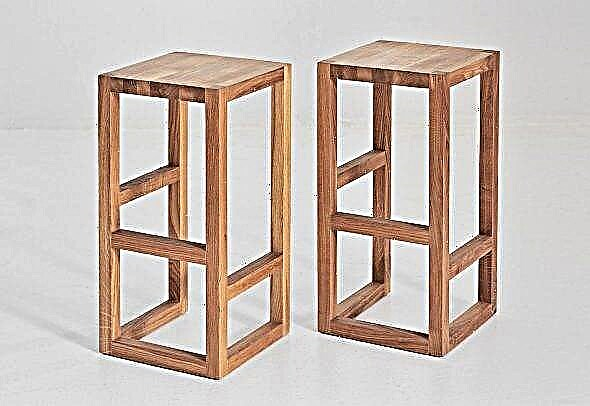

Modern stylish design and high quality materials.

And what is a bar counter without chairs? They can be both ordinary and special, but at the same time comfortable. Of course, the easiest way to buy them in the store. But not everyone likes the offered range. Yes, and they are expensive. If you are a fan of unique and outstanding things, do not be lazy and make such a chair yourself.

Many owners of apartments and private houses equip their kitchen or living room with a bar counter - a very convenient and functional piece of furniture.

DIY Benefits

Many craftsmen make the necessary interior items, including chairs, with their own hands, while receiving pleasure. Try it and you. Drawings can be made independently or found on the Internet. You can become a master of your craft in this specificity. And from a hobby, your interest will turn into a profitable business. In addition, making furniture with your own hands, you will delight your relatives, friends, acquaintances by doing something original for them. A unique interior will appear in the house or apartment, among other things, you will significantly save the family budget.

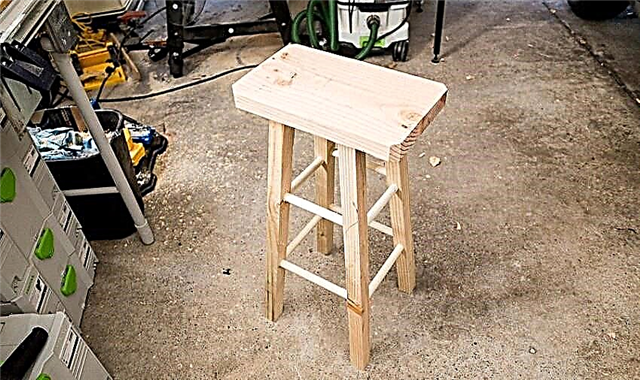

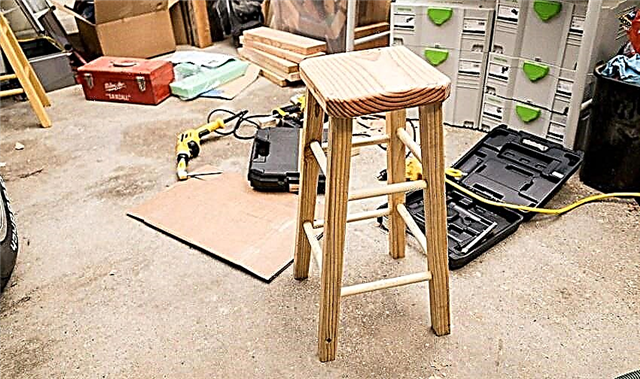

So, let's try to make a bar stool with our own hands.

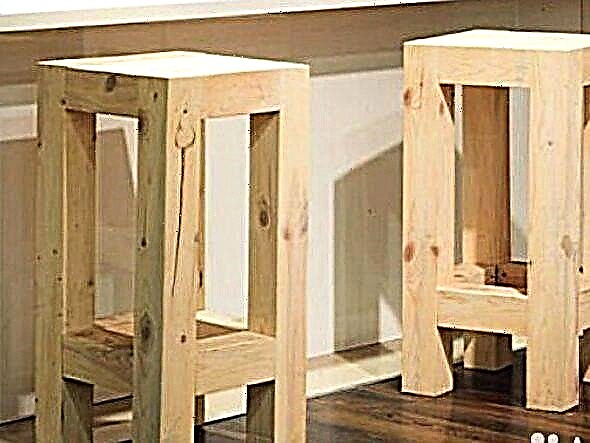

A worthy addition will be the original and at the same time comfortable bar stools.

Determine the design and construction of the bar stool

First you need to think about how high the chairs will be. It directly depends on the size of the bar. Consider all the nuances - you should be comfortable sitting on chairs. Of great importance is the design. Furniture should be combined with the design of the kitchen and be suitable for other interior items.

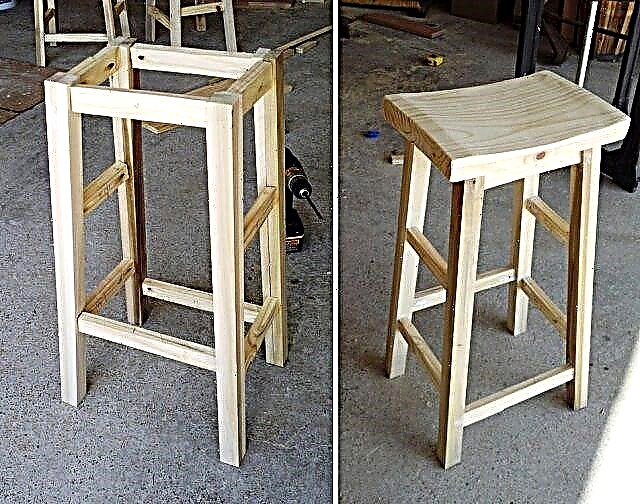

The simplest version of the bar stool is made of wood and plywood.

When choosing a design, many factors are important:

- the number of legs, the most reliable is four,

- height adjuster

- it is convenient if the chair has a footrest, back and armrests (these parts of the chair should be necessary if the bar counter serves as a dining table)

- the upholstery and the material from which they will be made. (it depends on whether the chair will be sturdy or not).

Depending on the option you choose, you need to take a solid wood or plywood.

Necessary materials

Use a variety of materials - metal, wood, plastic. Wood is better suited for bar stools, namely varieties such as oak, beech or maple. All that is required, you will get in any hardware store. Materials can be ordered in the workshop. We need: a panel massif (drawers) 25-30 mm, the approximate diameter of the array for the seat is 360 mm, a beam of 50x50 mm (legs), carpentry glue, foam rubber, upholstery fabric. Impregnation or paint may be necessary to cover the product and protect it from moisture.

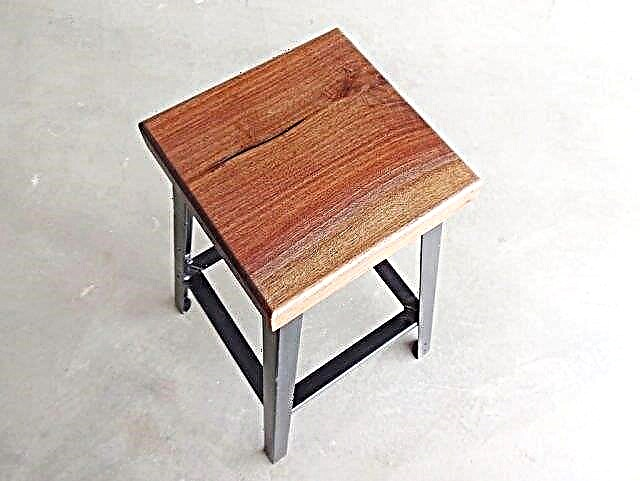

You can use metal, but in this case the work will be more difficult.

Necessary tools

Before you begin, you need to stock up on the following tools:

- marking pencil,

- roulette,

- elbow

- hacksaw,

- sandpaper,

- fixture for legs,

- drill,

- drills on 3 and 6 mm,

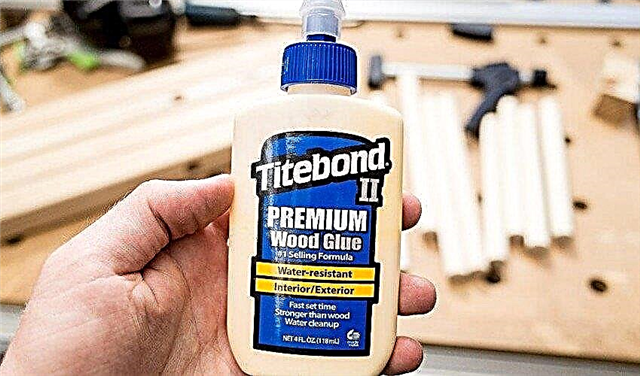

- glue,

- self-tapping screws (5x20, 5x30, 5x80),

- bit,

- hammer,

- screwdriver.

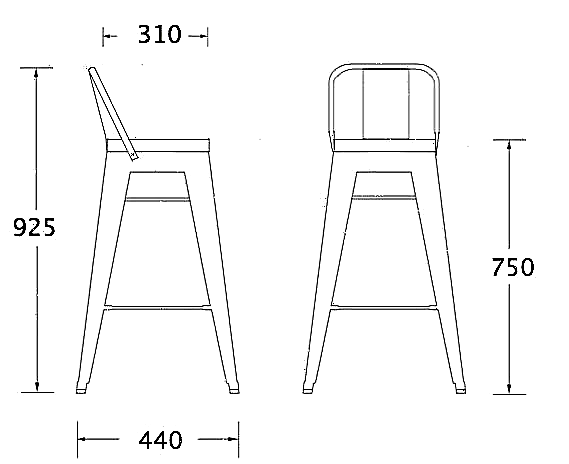

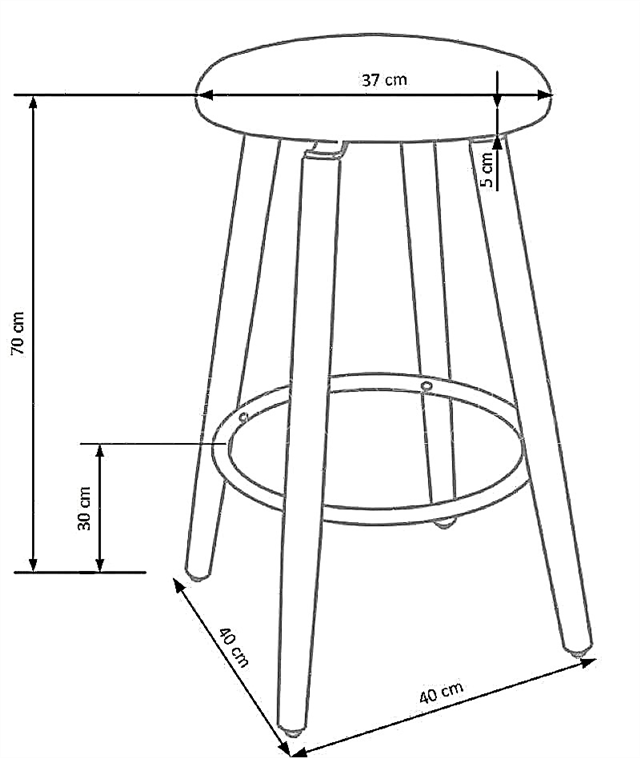

The standard sizes of bar stools are calculated based on the distance from the bottom surface of the countertop to the floor.

Manufacturing process: step by step instructions

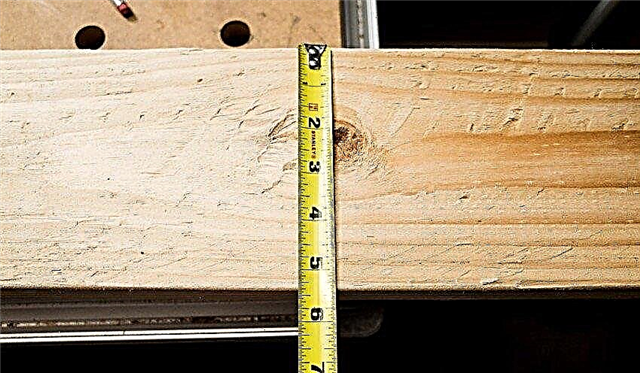

To establish the height of the bar stool, you need to measure the length from the countertop of the bar to the floor. The distance from the seat to the rack should be 30-35 cm.

The gap between the chair seat and countertop is usually 30–35 cm.

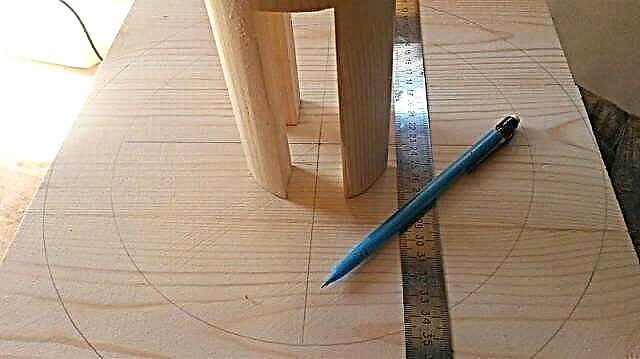

Prepare drawings with exact dimensions before work. This will help to know the amount of material. At the initial stage we collect all the necessary details. We make markup on the workpiece. Using a jigsaw, we cut out a circle from the array, the diameter should be 360 mm - this is the upper part of the seat. Now it needs to be sanded with a machine. Then cut out a smaller circle - 260 mm. It will be needed to assemble and attach the legs.

Based on basic data, you can create your own product design

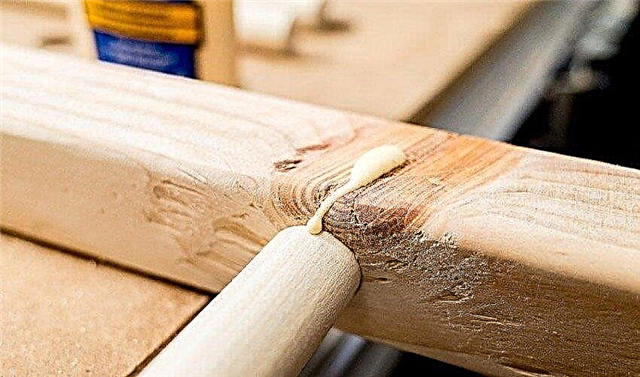

The seat can be made square - at the discretion. To do this, take a wide tsar or two or three planks with a width of 120 mm. To connect them, we pierce a spike and a groove in the end side. We glue the parts with carpentry glue or PVA for furniture, we connect them, then we fix them and leave them to dry completely.

When choosing wood for the product, pay attention to the most affordable species - pine and birch.

We proceed to the manufacture of legs, we make them from a beam of 50x50 mm. Be sure to keep the structure upright. We plan the entire length with a plane so that the section at the bottom of the legs is 2.5x2.5 cm, and the place of attachment to the seat is much thicker.

The required thickness is 20 and 30 mm.

Still need four so-called cuticles. This will help to significantly fix the structure and become a support for the legs. The beam 2.5x2.5 is cut out, a thorn is sawed in the end part. In the legs we make a nest under the spike. We distribute it at a height of approximately 30 cm from the floor. Grease the little sticks with glue, insert into the nests and firmly fix. Let it dry.

Some details can be borrowed from old chairs.

Now collect the bar stool. It is important to prevent gaps and crevices. Then, as the parts fit, we connect them. The pointed corners of the spikes must be rounded.

- In the circle for attaching the legs, it is necessary to drill 2 holes of 6-8 mm in diameter for each leg for dowels. They should be strung on them with a strain. In addition to the legs, metal corners are attached with screws.

- A circle of a larger diameter is attached to the screws on top from the back. Now set the chair on a straight plane and adjust the legs.

- We thoroughly process the chair with a grinder, varnish or stain, preferably in several layers.

Cutting out the legs of the future chair, make sure that the structure of the tree in the array is vertical.

In some cases, you can install the back and armrests. If desired, the seat can be made soft. Before covering the bar stools, they put on foam rubber, batting, a children's mattress made of coconut coir is suitable. Upholstery fabric must be solid, of good quality. Faux leather is also suitable.

20 mm thick, cut the stiffeners - they will serve as a footrest.

On the back of the seat we apply a layer of glue - furniture PVA or BF-88. Lubricate the filler with glue, say foam, and upholstery.

The ribs are attached to the legs with the help of the corners, which are set from below, on the side of the floor.

Foam is pressed firmly to the seat and covered with upholstery. We fasten the stapler first in the corners, then around the perimeter.

The diameter of the holes for self-tapping screws in the plane should be 6 mm, in the end - 3 mm.

The final stage - decoration

Bar stools are ready. Now let's start decorating. This is an interesting and fascinating process. Having mastered this art, you can give a unique look not only to newly made furniture, but also requiring updating. There are several decor methods. Let's get acquainted with some of them.

Such bar stools are very simple in execution and convenient to use.

Dressing with fabric. First you need to choose the type and color of fabric. It must be durable. It is necessary to take into account the overall interior of the kitchen. Take, for example, a tapestry. By structure, it is 100 percent cotton and artificial fibers. It is quite strong and durable. Equally use jacquard, microfiber, furniture silk - it is better suited for rare furniture.

The peculiarity is that the seat can be made straight or bent, and subsequently, if desired, upholstered with fabric.

If you don’t want to bother with the hauling, just sew the covers. This will update your interior.

For the legs of the chair, use bars of 38 X 38 mm.

Recently, designers have preferred decoupage as the most winning decoration technique. Everything is elementary. The plane is treated with sandpaper, putty putty, painted. It is better to work with white water-based paint. Against this background, decoupage is as delightful as ever. After sticking decorations from special napkins. Or use floral and vintage pictures. The final stage - finishing painting and coating with acrylic varnish.

You can take poplar wood if there is no pine or birch.

The legs will be 71 cm long.

There are simple methods that are widely used at home. The most common is painting. It is better to use spray cans. A variety of colors will give the product an attractive look.

To be comfortable, set the height of the footrest according to the growth of people.

Decorating with a jute rope will create special warmth and coziness in the house, wrapping it around a bar stool.

To establish the height of the bar stool, you need to measure the length from the countertop of the bar to the floor

Using these and other methods, you will create an exclusive home furniture that will fully meet your desires, where you will feel cozy and comfortable. Having created such an atmosphere, you will be happy to return home after a busy day.

The seat can be made square - at the discretion.

It is important to prevent gaps and crevices.

What tools are needed?

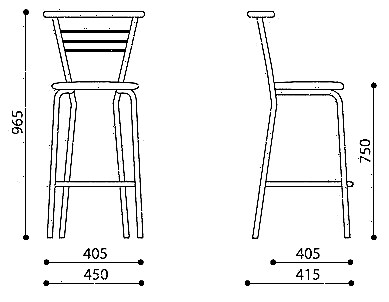

Here you need a standard set of tools, materials and a correctly drawn up drawing. Such a homemade chair is a product with high legs about 80 cm high, and there is a special footrest at the bottom. High coasters are very comfortable, legs do not sag or get tired during sitting.

The height may vary depending on the dimensions of the bar in the kitchen. A person should feel free and not be afraid to lose the center of gravity, despite the fact that the chair is above standard sizes.

Materials and Tools

You can make a bar stool yourself from metal, wood or plastic. The model can have a round or square shape, complemented by one or more steps. Regardless of the design, the assembly principle does not change.

The base of the bar stool carries the main load, is responsible for stability. The choice of raw materials should be treated wisely.

You can assemble the product completely from a single material or combine different ones. So, the legs are usually made of metal to increase the strength index, and the upper part is made of wood for a presentable appearance. It will give airiness to the seat made of transparent plastic.

Metal is the most durable material, ideal for creating a frame. It withstands severe loads, frequent operation. But he remains cold, sitting on such a seat is unpleasant. Wood is slightly inferior in strength, but it looks more expensive and more aesthetic, plastic is less durable, looks like an element of garden furniture.

The list of necessary tools will vary depending on the selected raw materials:

| Tree | Metal | Tool | Why is it necessary |

| + | + | Screwdriver | Work with screws and other threaded parts |

| + | + | Roulette | Fixing exact dimensions |

| + | + | Pencil | Setting notches, restrictions, marking |

| + | + | Square | Fixing the right angles to create a symmetrical and sturdy construction |

| + | + | Hacksaw | Correction of harvested parts |

| + | + | Sandpaper | Sanding parts |

| + | — | Chisel | Helps to clean grooves, create a decorative pattern |

| + | + | Fasteners | Strong connection of parts, assembly of the structure |

| + | + | Drill | Drilling holes |

| + | + | Bit | Punching grooves and holes |

| + | + | Jigsaw | Cutting parts |

| + | — | Glue | Bonding parts |

| + | + | Brushes | Application of varnish, paint, protective compounds |

| + | + | Lacquer | Gloss Finish |

| + | — | Plane | Editing workpieces, giving a more accurate form |

| + | + | Screwdriver | Drilling holes, screwing fasteners |

| + | + | Hammer | Any work of the shock type from driving nails to the solid connection of the structure in the grooves |

| + | + | Solvent | Suitable for thinning paint and varnish for topcoat |

| + | — | Stain | Needed for painting wooden parts of the structure |

A complete set of tools will help to make a bar stool made of wood or metal with your own hands or to combine materials. Experts recommend assembling tools in advance so as not to be distracted by the assembly process.

Drawing up a drawing

Blindly, you cannot create products. A drawing with precisely marked dimensions is required. The standard sizes of bar stool chairs are as follows:

- height to seat - up to 85 cm,

- seat width - from 30 cm,

- the minimum distance between the legs is 40–45 cm.

Some models suggest the presence of a back. Its height should not exceed 25 cm. All measurements are made in the drawing. You cannot change the dimensions during the assembly and preparation of parts.

The height can also be adjusted based on the height of the rack itself. The distance from the floor to the seat is equal to the height from the floor to the countertop minus 30 cm.

Working drawings fix the main dimensions, nodes. If you plan to make a sliding product, all parameters are already indicated in the extended form. The scheme itself can be obtained in several ways:

- Download from the Internet. No one guarantees the correctness of such calculations. There is a risk of wasting materials, getting low-quality results.

- Create in a computer program. The software allows you to create an accurate drawing of the product. Requires skills to work with such software.

- Draw by yourself. The easiest way. It takes a piece of paper and a pencil. But it is advisable to check all the calculations several times.

The correct drawing is a guarantee of a good result. Therefore, do not take the first one that catches your eye. If the choice fell on the option posted on the Internet, it is useful to familiarize yourself with the results of those who have already used it in their work.

DIY making

Do-it-yourself bar stools are made for home, for sale. Having decided on the materials, sizes and tools, you can begin to study the drawing. Then they begin to prepare parts and assemble the structure. Additionally, you can create a cover or decorate furniture with pillows.

Wooden

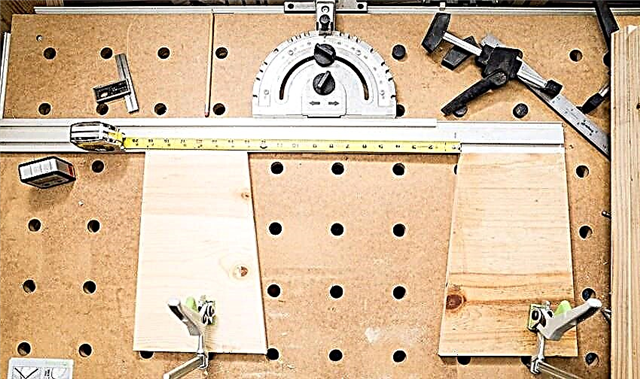

Wooden furniture fits into any interior. Aesthetic appeal, malleable material, durability are only part of the advantages of wooden chairs. Several shields up to 3 cm thick, a jigsaw, pencil, plane, screwdriver or screwdriver, screws, sandpaper, stain and brushes are prepared in advance. Follow the instructions:

- Prepare a drawing. Check dimensions, check for tools and materials.

- Pencil markings are applied to the shields.

- The main parts are cut out with a jigsaw. For a seat you need a circle with a diameter of 35 cm, a backing - 25 cm. It will take four legs with a thickness of 3 cm and four footrests.

- The plane is planed legs so that downward the thickness is reduced by half a centimeter.

- A screwdriver or screwdriver will help to assemble all the details. 5 x 80 screws are suitable for connecting the legs to each other and the substrate. 5 x 40 screws are suitable for screwing the seat to the substrate.

- Last of all, with 5 x 20 screws, stiffeners are attached to the supports.

- With sandpaper, sand the entire product to a smooth state.

- Coated with stain or varnish.

In the same way, you can assemble a chair from plywood, natural wood. The wooden bar stool can be left with a natural color and texture or painted in the desired shade. The paint is selected non-combustible.

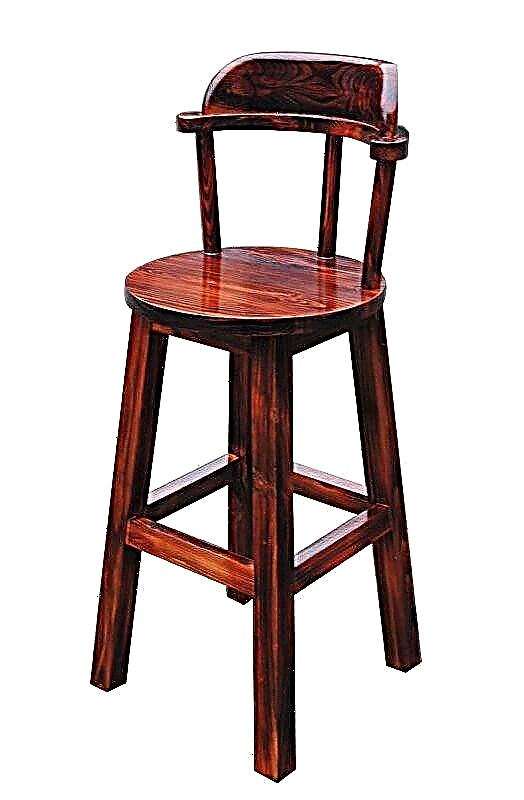

With padded seat and back

Soft chairs are more comfortable, but making them yourself is more difficult. As a material for upholstery, genuine leather or a substitute, textiles, velor, jeans and any material capable of withstanding frequent use are used. Sizes are selected with allowance for the connection.

Fabrics soaked in acrylic or teflon are ideal. They are easy to clean, do not absorb liquids.

To create such a piece of furniture you will need a jigsaw, pencil, wood or shields, sandpaper, hacksaw, drill, chisel, screwdriver, brushes, varnish or stain. The following details are marked in advance:

- seat - 34 x 34 x 3 cm,

- front legs - 2 x 44 x 74 cm - 2 pieces,

- hind legs - 2 x 44 x 99 cm - 2 pieces,

- front drawer - 2 x 44 x 27 cm,

- rear tsar - 2 x 44 x 32 cm,

- lateral connecting strips - 2 x 44 x 30 cm,

- stitches - 2 pieces of 1.5 x 22 cm,

- 4 pieces - 15 x 30 cm each,

- crossbars for the back - 2 pieces of 2 x 44 x 38 cm.

All details are cut out with a jigsaw; a chisel may be required. Elements are cleaned with sandpaper. Details of the front part are cut in an arc. At the rear, with a drill or chisel, 2 x 2 cm connecting grooves are punched. Using a hacksaw, spikes are made on the drawers, holes are drilled on the side strips with a drill.

On the legs make nests for the made spikes. Pass through the entire structure with sandpaper and collect the remaining parts using self-tapping screws and a drill. At the end - open the product with varnish or stain. The upholstery is attached with a construction stapler. For the substrate use batting, furniture foam (cut in the shape of the back and seat). For convenience, you can use glue for furniture. The seat is assembled separately, then fixed to the finished structure.

From a profile pipe

The easiest option for those who want to get a quick result. It looks authentic, suitable for any bar table. A frame is assembled from the profile, then complemented by decor. Stainless steel is durable, easy to operate. Numerous workshops provide information on how to make a bar stool with your own hands from a profile pipe:

- Prepare materials and tools. You will need plywood or a sheet of chipboard, pipe benders, a drill, a screwdriver, a construction stapler, foam rubber, textiles (any suitable upholstery).

- Cut the blanks so that they correspond to the working drawing.

- The upper parts of the pipes are bent with a pipe bender, give them a semicircular shape.

- Connect the bent parts with a screwdriver and fasteners.

- The seat is cut out with a jigsaw, furniture foam rubber is prepared under it, the upholstery is cut. Glue foam rubber with a glue, tighten with a cloth and fasten with a construction stapler from below. Attach to the finished frame with bolts.

- From the bottom, plastic plugs are pulled on the legs so as not to damage the floor.

You can assemble the structure without a pipe bender. Instead, the frame is assembled from pipes of different lengths, connecting with metal corners. Such a chair will be more durable and stronger than a wooden one.

Decor Options

A simple bar stool looks attractive. Additionally, it can be decorated using decoupage technique. To do this, you will need special glue, finished patterns on a thin base and varnish as a topcoat. The method is suitable for wood products.

The tree goes well with jute rope. It wraps individual parts of the structure or the entire seat and legs to the crossbars. Fabric upholstery, covers, any decor serves to ensure that the chair blends well with the interior and bar. The easiest way to decorate - painting in one tone, applying patterns using stencils, self-applying drawings.

When choosing a decoration method, the material of manufacture and the frequency of operation should be taken into account.

The bar stool is easy to make with your own hands. It is enough to stock up on materials and tools, prepare a drawing and begin the creative process. A piece of furniture can be left in its original form or decorated. The counter, supplemented by several such armchairs, will become a real decoration of the interior of the kitchen or living room in the studio apartment.

Painting

Painting  Varnishing

Varnishing  Decoupage

Decoupage  Art painting

Art painting  Upholstery

Upholstery  Sewing covers

Sewing covers

Making a model from plywood

Wood is a plastic material that can be easily processed. You will need tools:

- The grinder with a disk like - "saw",

- Grinder machine,

- Roulette,

- Drill and screws

- Glue.

- Chisel,

- Screwdriver.

Performance of work

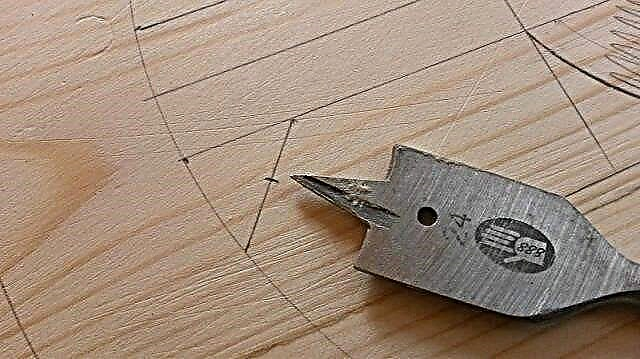

At the very beginning of the work, elements of future wooden legs are cut out of wood. Marking in the form of the letter A is applied to the tree, decorative curves are made at the intersection points.

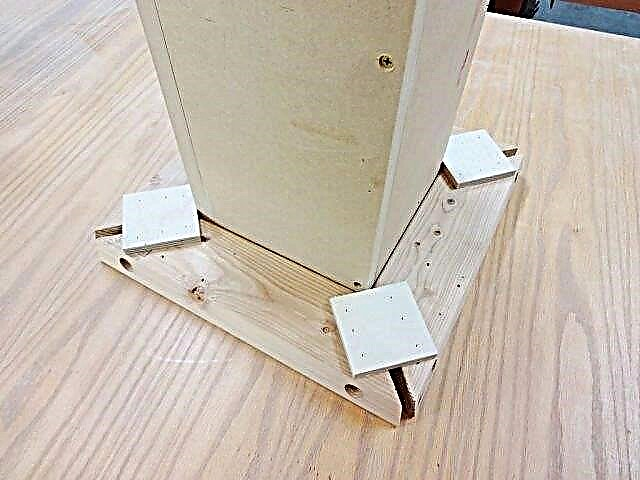

The elements of the legs are cut with a jigsaw according to the drawn markings. Thus, it turns out the block - the future leg support. This is an important connecting element: there will be few fasteners, so the leg support is reliably obliged to fasten the supports, which should withstand decent loads.

The chair should be strong and not "hang out" at the points of attachment of nodes. All places of cuts are processed by the grinder.

After the details of the legs are done, it's time to assemble the supports. Four blocks of legs are carefully smeared with glue and mounted close to each other overlay. After the glue hardens, for greater strength, self-tapping screws should be wrapped in the fastening points.

The footrest is cut out of plywood. If the thickness of the material is insufficient, then the cut pieces of plywood can be glued and joined.

The seat is made using the same technology. The cut pieces are joined, which are well pre-glued. You can make several layers of plywood, taking into account the possible large loads.

A special backing for the seat is made, it must be strong enough, because the legs will be attached to it.

Fastening occurs with the help of screws. When everything dries and is collected, the stage of varnish-and-paint work will come.

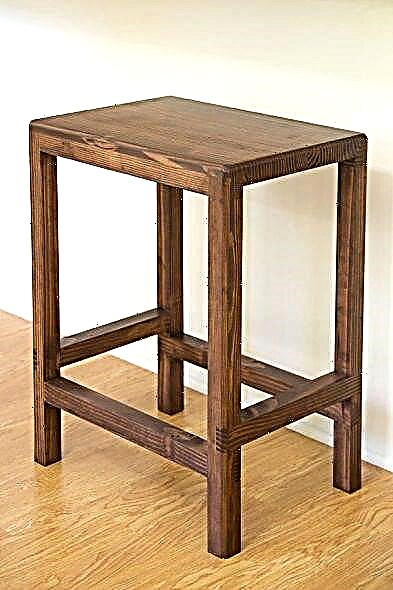

Solid mass product

The best option is to make a bar stool from a solid array:

A birch massif is preferable; pine is not always uniformly painted over.

When making a chair from a solid array, you need to consider - the thickness of the material should be at least two centimeters.

A circle with a diameter of 370 mm is cut out - this will be the future seat. If the house does not have special woodworking equipment, then a profile is drawn along the contour, cut out, the surface is processed by a grinder.

Then a circle smaller than 250 mm is made - this is the part that will be the footrest. All elements are also carved from solid wood, moreover, wood fibers must go along.

Then they are connected with glue, the back is attached with self-tapping screws. Such fastening is enough to make the structure rigid and durable. After grinding is completed, you should carefully paint over the resulting object, cover with several layers of varnish.

A chair made of solid wood is heavier, but also more durable. It is easy to stylize antique, then it will look very original. In this style, you can make more than one product. A similar thing will serve for a long time, it is not afraid of changes in humidity or temperature.

Technological flaws in wood

Wooden furniture is in constant demand, but it also has its drawbacks:

- Moisture susceptibility is the most dangerous factor that spoils wood,

- The anisotropy of the structure affects different characteristics of wood fibers located along and across,

- Timber is combustible and susceptible to fungal diseases.

If wooden objects are present for a long time in the fresh air, for example, on the veranda of a private home, then it is likely that they will deteriorate, especially with regard to products in which plywood is present.

Metal fabrication, first option

Metal is durable, and products from it are no less elegant than from wood. To make bar stools from metal is not very difficult. We need appropriate materials and elementary skills in welding.

Preparation for work consists in the fact that, first of all, the appropriate tools are selected. First of all, you need a pipe bender, you can create it yourself. On the layout, the bars should be fixed and between them leave a space equal to the diameter of the pipe. Two beams should be at least 5 cm thick.

Pipes are filled with sand, inserted between the bars, and then the operation begins to give them the desired shape.

Start of creation

Before you start working, you should draw diagrams in order to first imagine what the object will be on high legs. Samples can be found on the Internet, where there is a huge variety of models, it is also easy to find a description, and even diagrams and drawings. After the model is selected, it will become clear what dimensions will be, the creation of the product in three-dimensional space begins:

- First of all, a stencil is made on a scale of 1: 1, it will become the standard for future manufactured blanks,

- Two pieces of a profile pipe are cut up to two meters long (this will be the future frame),

- The crossbars will also be from the pipe, therefore, pieces of two pieces 0.5 meter long will be required,

- The rear legs will also be 0.53 m,

- All material is cleaned with sandpaper,

- The pipes are bent in accordance with a given pattern.

Assembly of parts

Holes are drilled at the attachment points. Then the parts are assembled together, and iron cylinders are inserted into the holes. After this, the fabric blank is taken, and two pieces are cut from it in accordance with the template, which will be the seat and back.

They are stitched with a double seam and put on a finished frame. Behind the screws attached legs.

For fasteners, 5x80 mm self-tapping screws for legs can be used. The seat is screwed to a small circle using 5x40 mm screws. The installation of stiffeners can be done with 5x20 mm screws.

The ribs are mounted on the legs using the corners. The thing is ready.

Metal stools are more and more common, with backs and armrests which can have strong iron or copper tubes.

If there is a bar in the house, then the chairs for it will be very out of place. Do-it-yourself products can last a very long time, they are not afraid of either high humidity or large mechanical overloads.

Second option

If the idea came up to create chairs yourself, then it is recommended to analyze several manufacturing algorithms for these simple objects. The second option may be preferable especially for those who know how to use the welding machine.

To get started, prepare the tool:

- Reiki about 20 cm wide,

- Metallic profile,

- Scissors,

- Welding machine,

- Sander,

- Sandpaper,

- Ruler

- Elbow,

- Marker,

- Roulette.

In a short time, it is easy to create an original product that can “work” for many years.

Finish

Metal - the material is hard, be sure the ends of the legs are insulated with rubber or wooden nozzles. After the manufacture of the product, the finishing period begins: the finished thing is primed and painted.

It makes sense to put several layers of soil and paint, which will guarantee long-term successful operation of the thing.

See how to make bar stools with your own hands in the next video.

Design and construction choice

Having opened any catalog of bar furniture, it is simply unrealistic to suddenly stop looking at a specific model, because the variety of shapes and colors is amazing. However, it is not always possible to find something suitable for your interior. In this case, it is worth making the furniture yourself. At production of bar stools it is necessary to consider a number of important parameters.

Properly calculated chair height is the key to convenience. The optimal distance from the seat to the bar counter is 25-30 centimeters. The presence of such a space provides comfort and freedom of movement.

A large surface area of the furniture contributes to relaxation, immersion in the atmosphere of comfort. However, not every bar table can allow a wide scope. Thinking about making a chair yourself, you need to calculate the size of the seat based on the width and depth of the countertop. It is advisable that during operation there should be no interference within a radius of 20 centimeters. This will provide comfort without violating the personal space of a person sitting at the bar.

When developing the design of the chair, it is necessary to consider the following components:

- Base. Of course, everyone has different preferences, but experts recommend the use of four legs. They will give the bar stool maximum stability and reliability. It would be useful to think about the possibility of adjusting the height, provided that among family members, relatives, acquaintances there are people of different stature.

- Back. For snacks or other short-term use of the chair, this parameter is not particularly important. If you plan to sit for a long period of time, then it would be reasonable to opt for a high, well-fixed back, which you can lean back at any time.

- Armrests. This design element is voluntary. There are no specific recommendations. It all depends on personal preference.

- Upholstery. Its presence is due to the prioritization between style and comfort. Rigid chair seats made of metal, acrylic, plastic, wood look more stylish, blending in perfectly with the modern interior. Soft models, covered with fabric or leather, are pleasant to the touch, more comfortable.

The deciding factor in the design choice is the overall interior of the room. Traditional furniture, for example, would not be appropriate to look in a room decorated in the styles of hi-tech, bionics or brutalism. Do-it-yourself bar stool should harmoniously fit into the design of the room, not get out of the picture.

The color of the furniture is best chosen based on the overall color scheme of the room. This is especially important for the foundation. But as for the seat of the chair, it is recommended to give free rein to imagination. You can choose from a plain design to floral or animal prints. Then the bar stool will become a bright highlight in the interior.

What materials can be made

The base is a kind of foundation for the entire product, which takes on the main load, is responsible for reliability and stability. Therefore, if among those who will sit on a bar stool, there are people with a weight exceeding 90 kilograms, preference should be given to more durable materials. These include wood, metal. The latter looks very expensive, solid, but gives the product significant weight.

If a decision is made not to use upholstery for a seat, then this structural element can be made of natural wood. This noble material will give the bar stool the look of expensive, status furniture. Its disadvantage is its high cost. Use of plastic is allowed. Particular attention should be paid to the transparent version. It is appropriate when creating an atmosphere of lightness and airiness. However, one should not forget that this material is not durable and, as a result, can crack during prolonged use.

If you decide to make the seat softer, more comfortable, you can choose textiles or leather as upholstery. Natural materials are more suitable for the classic execution of a bar stool. Artificial ones are best used when creating high-tech products and the like.

You can make a bar stool yourself from one material or combine several options.This will give charm to the details of the interior, will make it possible to realize any fantasy. In addition, such a design will positively affect the final cost and functionality of the product.

Why on your own?

Of course, we are not saying that you should forget about furniture stores, but instead do all the furniture yourself. But if you look at the photos of bar stools, which can be found in numerous catalogs of furniture stores, then we can conclude: such a chair is really possible to make yourself!

Bar stools are easy to do yourself

In addition, home-made pieces of furniture can become a true decoration of the house, pleasing not only the look, but also the soul.

On a note! Even in this case, there are more opportunities, because you decide which option is best for the interior of the room. It is not worth mentioning once again about people who like to work with their hands.

Original bar stools

Determined with construction and design

First of all, determine the size of the chair. Its height, for example, will depend on the height of the bar itself. Also remember that your bar stool should be not only attractive, but also comfortable, in all aspects. Once you have decided on all this, proceed directly to the design.

Height-adjustable bar stool

In truth, you can start with the appearance, but then it may turn out that, due to ergonomic features, some adjustments are required.

Simple wooden chairs without backs

As for the design, first of all, decide how many legs the chair will have and whether they will be at all. The best option is a product with four legs. It is easy to manufacture, convenient and reliable.

The four-legged chair is more reliable and easy to manufacture.

Important! A chair with a back will be even more comfortable, especially if you add armrests to it. If you plan to sit on such a chair during meals, then think about the back in advance.

Chairs with backs are more comfortable

Pay special attention to the upholstery (if it is planned). The chair, made entirely of wood, will fit perfectly into almost any interior, and after coating with varnish / paint and in other cases it will also look good.

More about the height of the bar stool

The creator of the first bar stool is not known. One can only guess that it first appeared around the time when instead of the usual partitions between visitors and the seller, tall (1.1-1.3 m) counter tables with comfortable worktops began to be used. From such racks, visitors to drinking establishments no longer had to leave. As a result, the usual "tripod" chair was transformed into a bar stool. For more noble bars, they were made of valuable wood, trimmed with leather and fabric, the poor public was content with cheap options. But even despite the practicality and high “growth”, all varieties of bar stools remained in the shade for a long time due to the outstanding design.

Standard height of a bar stool and racks in accordance with GOST

GOST 17524.2-93. Furniture for catering. Functional dimensions of seating furniture. Download file (click on the link to open the PDF file in a new window).

Everything changed in the fifties and sixties of the last century, when high chairs that became fashionable attracted the attention of large enterprises. Since then, much has changed, today the designs are very diverse: there are models with and without armrests, with backs, spinning and static, soft, with removable pillows and without upholstery ... The changes also affected the material of manufacture - now they use not only wood, but also chrome, aluminum, plastic. A variety of decor allows you to apply it to all possible stylistic decisions!

Despite all this, when choosing a bar stool, its convenience is of great importance. Due to the center of gravity, which is shifted forward (the visitor rests his elbows on the rack), the support is not the back, but just the footrest. For this reason, the backrest is more a tribute to tradition than an ergonomic condition. As for the landing height, it, as already noted, depends on the height of the bar, and therefore modern chairs are either produced in two sizes (Th and Bh), or equipped with a gas-lift mechanismthanks to which it is possible to easily adjust the height of the seat (within 54-85 cm).

What happens if the bar stools are wrong

Which tree to choose?

If you plan to make a wooden bar stool, then remember: it will require about 10 finished elements. The same applies to designs made of other materials.

For self-made chairs it is better to use wood

When choosing a material, give preference to hardwood (such as oak, maple, beech). In principle, a tree is best suited for self-production (although there may be exceptions, which we will discuss later) in terms of the effort-result ratio. Moreover, wooden chairs will look great in an apartment / house.

The tree for chairs must be hardwood

Having chosen a suitable drawing or having made it yourself, get materials. Everything you need is sold in building supermarkets or hardware stores, while chair parts can be ordered ready-made in the workshop. If you specify the required dimensions, you will quickly and inexpensively cut out all the required parts of the structure.

You can order finished parts for bar stools in the workshop

On a note! There may be more details - it all depends on the chosen design. In addition, upholstery materials may be added. Also, after assembling the chair, it is recommended to soak it with a primer (if it was not covered with paint / varnish) to protect it from moisture.

The design of bar stools may vary.

Chairs after assembly need additional processing

But in the manufacture of a metal bar stool there will be some difficulties. This option is suitable for craftsmen accustomed to working with metal, having all the necessary tools and able to independently make all the details. Additionally, you will need to work by welding, if there are no connectors for fasteners.

Make metal bar stools harder

But a wooden product, unlike a metal one, is easier to assemble - for this you will need a hacksaw, a screwdriver, self-tapping screws and "sandpaper". Of course, the description is very superficial, but the difference shows well.

Country bar stools

Features of the manufacture of a bar stool

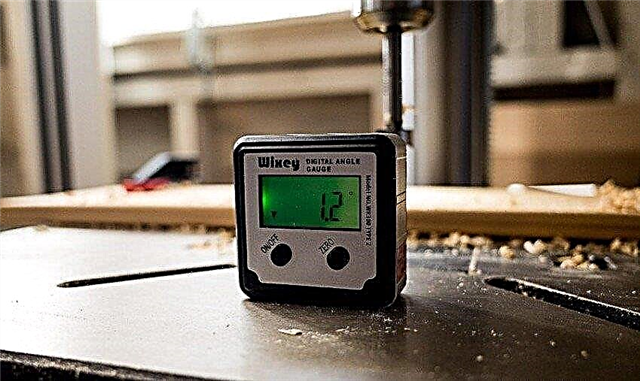

Despite the huge number of ideas (both in specialized magazines and on the Internet), the most important thing in all cases is the correct measurements.

The most important thing is the right measurements.

First, decide what the height of the chair will be. It is recommended that from the seat to the countertop should be approximately 35-40 cm. Having determined the height, make a drawing or use a ready-made one (select the appropriate option).

What determines the height of the bar stool

On a note! To make the simplest bar stool, you will need 4 legs, the same number of (preferably) cuticles and, in fact, the seat. If a back is planned, then the hind legs should be longer by about 30-35 cm (it will serve as the basis for the back).

Bar stools, their features

It is easy to make a mistake at any of the manufacturing stages - both during the preparation of parts of the structure, and during measurements. Therefore, it is recommended that all measurements be repeatedly checked before entering into the drawing or by cutting off an unnecessary part.

Check the measurements several times when making chairs.

The ready-made drawings already mentioned above will help with this, which is more relevant for people who have not designed anything before. Do not rush, try not “for show”, but for the result!

You can make a bar stool according to ready-made drawings.

Photo-example of the manufacture of a bar stool (master class)

Option number 1. Simple bar stool made of wood

The first thing you have to think about is whether the seat will be hard or soft. Not knowing which option to choose, make a firm seat, as in the example described below. In the future, at any time, you will be able to upholstery it with any available material (cloth, leather, etc.). The diagram below shows the design and dimensions.

Diagram of a wooden bar stool with dimensions

Step 1. For the legs, use wood 5x5x71 cm (in our example, this is poplar). Cut the chamfers / corners at both ends by about 5 degrees, so that the legs are inclined relative to each other. Drill pockets for connections.

Making chair legs

Step 2 Attach the lower / middle planks, removing the chamfer in the same way (all at the same angle of 5 degrees).

Installation of cross bars

Step 3 Having fastened all the parts standing in parallel, begin to fasten the transverse partitions to one of these sides. First deal with one side, then the other.

Fixing perpendicular partitions

Step 4 When attaching the partitions, take into account the fact that it should be comfortable to put their feet on during the operation of the bar stool. This is a prerequisite.

Partition Mounting Process

Step 5 The seat will have a special shape, thanks to which the chair will turn out even more comfortable. Mark the mark at the end of the board to be used for seating. To get the desired shape, use a circular saw, adjusting it to different cutting depths, although it is quite possible to use a conventional saw. Cut the recesses first and then remove the excess wood with a chisel.

Excess wood is removed through the recesses.

On a note! The process, of course, is quite complicated, and therefore, if there is something better at hand, you can refuse the bit. When you are finished with this, thoroughly clean all surfaces with a grinder.

Step 6 In the end, it remains only to connect the legs to the seat. To this end, drill holes in the upper part of the legs, make the same from the bottom of the seat, and then, using glue, put all the parts on the pins.

Leg connection and seat installation

The surface of the finished bar stool clean "sandpaper". Seal the holes with filler if necessary. Then you can paint the chair or, as an option, cover it with varnish.

Step 7 Everything, a simple bar stool is ready (and in our example there are three of them). Such a design - thanks to the competent placement of perpendicular rungs, comfortable sitting and selected height - could well become the most beloved and comfortable place in the house! Want to make the same chair? Feel free to get to work, because there is nothing easier!

This will look like finished bar stools made of wood

Option number 2. Backless bar stool with metal legs

Consider the process of manufacturing a simple stool made of walnut (seat) and metal. An old bed frame was used for the legs. The height of the structure is approximately 64 cm.

The simple bar stool we will make

A distinctive feature of the option is its shape, which makes it easy to weld and strengthen pieces of metal. If you plan to use a welding machine for the first time, then during the manufacture of such a chair you will certainly gain valuable experience and learn how to cook well.

The wooden part is made of walnut

Step 1. Start by creating a shape for the future design. Cut a suitable material (for example, chipboard) into four parts of 54.5 x 23.2 cm. All elements are fixed with a side joint using screws, resulting in a square "pipe" with a height of 58.5 cm and sides of 20 cm.

Need to cut 4 identical pieces

The result was a square "pipe"

Step 2 Make a corner base for the shape using a piece of board 9.5 cm thick. You need to cut the pieces into beveled shapes so that they all fit. To do this, find a suitable angle using a tape measure, and set it so that everything matches. As a result, after cutting, the beveled edges will be obtained.

First, find the right angle.

The desired angle is set.

You can start cutting

Prices for the popular range of face saws

Step 3 Pieces with the edges cut off at an angle of 45 degrees, adjust along the perimeter of the base part. Fasten the beveled base using plywood and small nails, as in the photo below. You do not connect this part with the “pipe”, and therefore it can be easily removed if necessary.

Pieces fit around the perimeter

Everything needs to be carefully monitored.

Parts are fastened with pieces of plywood.

Step 4 Thanks to the shape made, you can easily determine the location of the legs. No changes are required, you just need to attach and mark.

Future legs just need to be applied

The first leg is attached

First of all, mark and cut the legs from the bottom. To facilitate the process, you can hang the corner of the base above the edge of the table, and then fasten the iron part in place. Then cut off the lower ends.

The corner of the base can be hung over the edge of the table

The lower end of the leg is cut off

Cropped leg attached

After that, place everything in shape and proceed to mark the upper ends of the future legs.

Next, the upper ends of the legs are marked

Step 5 Use the 4 corners for the top of the structure. Mark everything you need with the previously made square. Glue the pieces together, then remove from the mold in order to fit the weld on each side.

4 corners are used for the top

Now the parts are welded together

Important! It is better not to put a vise, as in the photo, on a tree. Because the bolts, through which everything is fixed, can fly out, and everything will have to be redone.

It’s better not to put a vise on a tree

Step 6 Cut a few more pieces of metal to make a footrest. In our example, the length is about 30 cm, and the angle is 45 degrees.

Getting started with the footrest

Ready footrest

Step 7 A support with a footrest was held with the upper part of the structure and blocks for supports. Weld it all together. Weld a metal lining on the bottom of each leg. At the end of the work, sand all with “emery cloth” (the recommended grain size is 40).

The support is welded to the legs of the future chair

Metal lining welded below

Then everything is processed with sandpaper

Step 8 Now is the time for the walnut. Cut the main part into 2 thick boards, sand them with sandpaper. To grind the beveled edges, use the “emery” grit in the range of 100-220.

We start to make a chair seat

The wood is cut into 2 parts

Boards processed with sandpaper

Also, wood needs additional processing

Step 9 Treat the frame of the future design with a primer, and then with black paint. At the end, attach the wooden seat to the holes previously made using screws.

The seat is installed, the bar stool is ready for operation

Prices for various types of milling machines

Step 5 As a result, you will carve here such a stand.

Step 6 Start making seats and steps. They will be round, their diameter will be 31 cm. For greater strength, you can glue them from two shields, placing the lamellas across each other.

These parts stick together from two shields.

Step 7 Cut the ring out of plywood using the milling cutter. Using this ring, you will process the outer edges of the steps and seats, as well as the inside of the latter.

Using a plywood ring

Step 8 Like that. Inside, milling was carried out according to the copy sleeve, and outside - with a mill with a bearing.

Photo of the manufacturing process of the seat and steps

Step 9 Mark the footboard - put the center pillar in the right place, then circle the outline.

Step 10 Mark in the corner where exactly you need to make vias. By the way, a feather drill can “tear” a tree, if this happens - you will be forced to putty a lot.

Drilling vias are outlined

Step 11 With a thin drill, mark the point of passage of the tip of the pen. Next, drill a hole with the desired diameter with a pen drill, cut sections with a jigsaw, and then align everything with an “emery cloth” on the bar.

Steps for making a step for a bar stool

Advice! Experts recommend first making a plywood template and milling holes - in this case, you can get a higher cut quality, and work with the “sandpaper” to decrease.

Step 12 This is what the wood will look like after puttying the gaps left after the feather drill.

Photo of wood before and after processing

Step 13 Glue the workpieces of the legs from the bars.

Bonding leg blanks

Step 14 Give them shape using a plywood template. Act carefully and securely fasten the template with nails, otherwise it may be torn off the workpiece.

Plywood template ripped from workpiece

Step 15 Glue the cross-piece assembled in the grooves into the seat.

Gluing the cross in the seat

Step 16 Make the same grooves in the legs to assemble them.

Grooves formed in the legs of the chair

Step 17 After edge milling, proceed with assembly.

Ready legs of the future chair

Step 18 Sand the seat with special care.

Step 19 Pre-assemble the bar stool (no glue) to try on the details.

Construction assembled without glue

Step 20 Connect all the details together.

Joining chair parts

Step 21 After final assembly, apply stain and varnish to the glue. The result that you get will surely please you!

It looks like a finished chair

Table. The cost of manufacturing such a bar stool.

| Cost item | Amount in rubles |

|---|---|

| Lumber (we have them left) | 500 |

| Emery bar (180) | 70 |

| Stain, 2 species | 300 |

| Lacquer | About 350 |

| Glue | Spent it a little, you can not count |

On a note! In general, the manufacture of such a chair will cost about 1,400 rubles.

Option number 4. Chic bar stool made of metal

Consider another interesting option for the manufacture of a bar stool. It looks attractive and original.

Metal bar stool - decoration of your kitchen

Step 1. Draw on a piece of a dense sheet of asbestos that is used for welding, a pre-prepared shape (red lines in the photo).

Drawing a marking on a sheet of asbestos

Step 2 Cut according to the sketch of the workpiece using a 2.5 cm strip.

Blanks are cut according to the sketch.

Step 3 Weld the parts together, as shown in the photo below.

Parts are welded together

Step 4 Pick up the internal layout. Immediately make a reservation that this stage can take a lot of time. Use the same strip for the “chop”.

The internal layout is selected

Step 5 Weld the parts, clean them. Also round the corners.

All elements are connected.

Step 6 Proceed to the most responsible business - start welding the legs. Use a 3x2 cm profile for this.

Step 7 In our example, the author did everything by eye, i.e. did not make a drawing, did not measure angles, etc.

Leg welding process

Step 8 First, grab the legs by 1 weld point, and then gradually push them to the required positions.

First, the legs are welded onto one weld point.

Step 9 Here is what you get as a result.

Here is what should happen

Step 10 Indicate the level at which the foot rest will be located. Try on yourself, you need to be comfortable. In our example, this is 45 cm from the seat.

The level of an emphasis for legs is designated

Step 11 For the manufacture of stops, use the same 3x2 cm profile.

For stops, the same profile is used

Step 12 Perform tricky oblique cutouts for them, and then weld.

Another process photo

Prices for popular models of welding machines

Step 13 On the legs, put on special plastic plugs designed for steel profiles. Although you can, as in the example, make special heels of wood: they also will not scratch the floor, but you can grind them if necessary to ensure stability to the bar stool.

Making wooden corks for legs

Step 14 That part of the cork that goes inside the profile should narrow.

Narrowing the inside of the cork

Step 15 Such traffic jams will be held only by friction. Neither glue nor screws can be used. Sand the cork to the size of the legs.

Ready-made wooden corks for legs

Step 16 The draft version of the bar stool is almost ready.

Draft chair

Same top view

And so the chair will look in the interior.

Draft bar stool in the interior

Step 17 Start painting the product. First apply a primer coat.

First applied primer

Step 18 Blacken everything below the seat.

The legs are painted black

Step 19 Protect the black parts of the structure with something. So they do not get dirty during subsequent painting.

The black parts of our chair need to be protected

Feet wrapped in foil

Step 20 In our example, such a cardinal color for sitting was chosen.

Seat painting in red

Step 21 Everything, a metal bar stool made by yourself, is ready for operation!

Everything, the metal chair is ready for use