Drywall is one of the most common materials in construction, which nonetheless is very fragile. With it, not only sheathe ceilings and walls, but also create the most diverse decorative elements of the home interior. However, its inaccurate cutting leads to cost overruns, and the inability to produce it leads to unnecessary costs for specialist assistance. But do not be upset, because it is not at all difficult to cut drywall with your own hands, if you follow the instructions exactly.

Principle and rules for cutting drywall

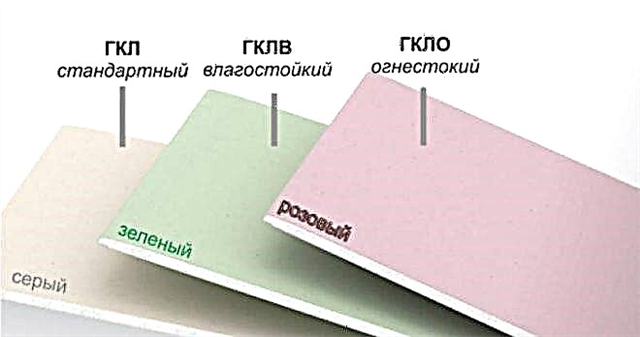

The principle and rules of cutting are based on an understanding of what you are dealing with, so you should first study the structure of the material. But in this case, the name speaks for itself - two outer layers are formed by cardboard, which serves as the basis for relative strength, and between them is enclosed gypsum with fillers. For various purposes, different types of drywall are used: standard, waterproof, fireproof. The first is used in all cases, excluding wall and ceiling cladding (moisture-proof drywall is used here) and structures located in the immediate vicinity of a fireplace or other heat source (in this case, fire-resistant material takes place).

Preparation and marking

Lay the GKL sheet on a flat horizontal surface and mark using a simple pencil, tape measure or ruler. A marker and a fountain pen are suitable for this procedure, but their traces are visible under the putty.

Immediately before or during operation, select the tool to be used for cutting. Before you opens up many ways to fulfill your plan, depending on the means you have. In fact, you can cut drywall with any sharpened object, but this will require certain skills. Consider the basic tools that can be used.

How to cut: tool selection

If you are going to cut drywall on a regular basis, or at least often enough, it is recommended to purchase a professional tool once and not to suffer from improvised means in the future. In any other case, you should have clerical - construction, reinforced - or mounting knives. Types of clerical are hardly distinguishable among themselves, but building is stronger. However, in any case, the cut from this knife is such that after it is necessary to eliminate the formed nicks.

For the operation being performed, a hacksaw for metal is quite applicable - its blade is thinner than that of a hacksaw for wood, so it wins in the accuracy of the subsequent result.

Another useful tool is a jigsaw. Its advantage is the lack of the need to think about how to cut drywall, because you just need to lead along the drawn line. To process the edges, additional tools are used, such as a peeling planer, the effect of which can well be reproduced with sandpaper.

When we figured out how to cut drywall, you can go directly to the methods of cutting it, the number of which is also large and varied. Let's consider some of them.

How to cut with a mounting knife

An assembly knife is suitable for cutting drywall into large longitudinal parts. First make the necessary measurements using a tape measure and a pencil, attach a metal ruler to the drawn line and start cutting the material with a point along the edge of this same ruler.

Be careful and take your time so that the cut comes out smooth and accurate and matches the line from the pencil lead.

The core is cracked with a light tapping, then the plate is turned over, and the drywall is again cut in the broken place. At the end, the material should be processed with a planer so that the edge becomes smooth.

How to saw with a hacksaw

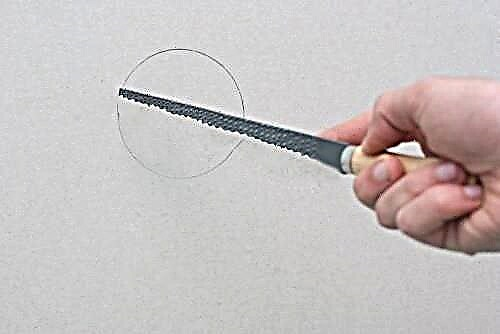

It is worth noting that most often a hacksaw is used to cut rectangular openings. In this case, you need to draw drywall on the reverse side. Drill a hole in a corner of the drawing with a diameter so large that the hacksaw blade can safely enter there. You can also make holes on all sides. After the operation is completed, the edge, as in the previous case, is processed with a planer or file, depending on the size of the hole made. Important: it is desirable for the tool blade to be perpendicular to the plane of the drywall sheet. In this case, the edges come out more evenly.

Jigsaw cutting

Jigsaw is the tool that will help save time and energy. Applying it, it is possible to saw and cut not only straight lines, but also smooth, curved lines and various shapes. If you use it, put the GCR sheet on two stools so that the previously drawn line of the shape of the desired cutout passes in the distance between the surfaces of the stools. Act smoothly and leisurely, cut strictly along the intended line. The jigsaw has another significant advantage: with it, the processing of the edges obtained is minimized, because it is held perpendicular to the surface of the sheet, which is the key to such a result. This is facilitated by the special sole installed in it. The disadvantages include the fact that you still have to spend money on it, but this tool is worth it. Also, when working with it, a lot of dust rises, you should take care of eye protection and respiratory protection in advance.

Figure cutting, as well as square and round cuts

It is worth paying attention to the above figured cutting. To saw the best, of course, a jigsaw is definitely suitable. But if the figure is, for example, a normal circle, then it is acceptable to use ordinary clerical or mounting knives. Initially, it is important to determine the center of the circle, and then draw it with a pencil and compass. Cut the edge of the intended opening as sharp as possible with the tip of the knife. Then place this section above the empty space - here again the construction of two stools is suitable. Slightly hit the cutout with a hammer - the material will break in the center of the hole.

Edge processing

A slice is treated with a peeling plane, since the edges never come out smooth and neat enough - this is a property of any tool, the experience and skills of the performer play a lesser role here. You can also chamfer with a regular knife, but it will take more time and require professional skills.

In conclusion, it should be noted that cutting drywall is one of the most common operations in the list of those that can easily be done independently at home, without the help of a specialist. It is enough just to approach any work with the mind and patience and carefully familiarize yourself with the sequence of the task, based on its features. Then the result will be appropriate.

We cut drywall with an electric jigsaw

Jigsaw - a file with a reciprocating movement of the file. Simply put, we are talking about a miniature version of an electric saw. In working with drywall, it allows you to:

-do curly cuts

-holes inside the sheet

- the most exact edges without nicks and differences of a contour

We cut drywall with a jigsaw

Jigsaw cut drywall along a pre-defined contour. Since gypsum dust will be knocked out from under the blade, make the markings with a black marker. It can be seen under the whitish sediments.

Lay out the sheets on the back. However, drywall is only the basis of structures, covered after tiles, wallpaper, plaster. Therefore, the markup side is not fundamental. Let's get started:

- We put the gypsum sheet on the stools or bricks, leaving the space under the cut line free. Also, there should not be voltage on the cut line. Its tearing forces will degrade the quality of the cut. Drywall is based on the basis of the flexibility of the material. Without support, the sheet may break under pressure in unforeseen places.

- We install a jigsaw at the start of the cutting line, or we bring drywall to the tripod of the tool, because it can be not only autonomous, but also stationary. Also, a number of jigsaws have a laser sight. It helps to “go” exactly according to the markup. In the case of work in the twilight, the backlight will help out. It is also not on all jigsaws.

- It remains to turn on the jigsaw and smoothly guide along the marking.

- In the final, we process the edges with sandpaper or a plane, a file.

Sort it out how to cut drywall with a jigsaw It is only with a tool. The most simple models cost from 1,100 rubles. If the spending is unjustified or there is no jigsaw already bought at hand, curly cuts are made ...

We cut drywall with a hacksaw

A hacksaw is also a kind of saw, but already a manual one. It costs a tool, usually a few hundred rubles. Canvas hacksaw is different. Need smooth with small teeth. This is a hacksaw for metal.

We cut drywall with a hacksaw

When working with drywall, it gives the most even cut. The thinness of the saw blade allows it to easily bend inside the sheet, passing precisely along curvilinear markings. Run the process:

- Marking drywall and making a drill or knife in its corners of the hole for entering the hacksaw blade.

- By inserting a hacksaw into the slot and sawing to the opposite point.

- Having processed the edges of the cut with improvised means.

Which side to cut drywall it does not matter with a hacksaw, but in which place it is important. When cutting a sheet from the edge, the tool gives a smooth, neat line, although it takes a considerable amount of time. Through holes on the drywall sheet, the hacksaw gives uneven. It is better to use a jigsaw.

We cut drywall with an installation knife

The mounting knife has interchangeable blades. There are blades for cutting different materials, the protrusion of the metal part beyond the limits of the handle is regulated. There are the same stationery models, but they are low-power for working with drywall.

You can even cut drywall with an office knife

There is an assembly knife from several hundred rubles. The tool is good when decided how to cut drywall at home in a straight line. Curly lines with a mounting knife are obtained anyhow. Proceed:

- We draw drywall according to previously made marks.

- We attach a steel profile for drywall or a metal ruler to one side of the marking. They will not allow the knife to go sideways during cutting.

- We put the blade to the edge of the marking and drive along it with a pressure of about 3 kilograms.

The knife should not go through the sheet. Properly cut drywall - This is to lead the blade with a recess of about half a centimeter. The rest will break along the line when you bend the panel with your hands.

The cut should appear at the top. For bending, drywall will need to be supported. You can simply put the sheet on the floor, or you can put it on chairs or the edge of the table.

The nuances of cutting drywall depending on its type

Drywall sheets are specialized, for example, waterproof. Paper on these is impregnated with polymers. They close the pores in the cardboard, making it resistant to moisture and reliable protection for compressed gypsum powder inside.

However, even the waterproof gypsum board edge is not protected. Accordingly, the workplace should not be wet. Once in gypsum, water will cause it to swell, and the geometry of the building sheet will change.

Arched Drywall

Separately, there is an arched drywall. It is as thin as possible, only 6.5 millimeters in thickness. It would seem that such a sheet is easier to cut than a centimeter. However, fiberglass is laid inside the arched panel.

It reinforces drywall and gives the flexibility necessary to deform a sheet intended for curved doorways, ceilings.

Due to the fiberglass inside, the arched material is cut harder than a simple drywall. It is better to use a power tool. An assembly knife or a hand file "go" hard.

General rules for cutting drywall

The gypsum microparticles inside the cardboard cover are light and volatile. Breaking out from under the paper during cutting, the mineral suspension rushes into the air, getting into the eyes, settling in the respiratory tract. Therefore, it is advisable to put on a protective mask.

It is recommended to lay a plastic film on the floor under the cut sheet by sprinkling it slightly with water from the spray gun. Moisture will help the gypsum particles flying on top to swell, get heavier and sink onto polyethylene. At the end of work, it will remain to collapse and throw it away. Particularly thrifty wash the film in the bathroom, dry and reuse.

If gypsum dust settles directly on the floor, washing the powder will be problematic. There will remain divorces. If there is a porous coating on the floor such as opaque porcelain tile, gypsum particles will clog into it.

A solution of warm water with sunflower oil at the rate of half a glass of product per 10 liters becomes salvage. After the floors are already wiped with vinegar.

For glossy surfaces, the method is not suitable. There it is better to do with a solution of potassium permanganate. It is added to warm water until it becomes light pink.

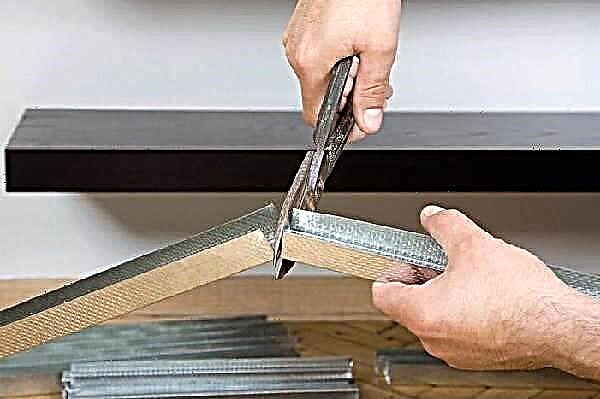

We cut a profile for drywall

Since work with the hero of the article has begun, the question is also relevant, how to cut a profile for drywall. It is used to create a frame for paper-mineral sheets.

They are attached to the profile on self-tapping screws. Accordingly, drywall closes the profile base. You can not focus on the accuracy of cutting steel bars. Their ugliness will hide the sheets.

You can cut the profile with scissors for metal

For cutting a profile for drywall use 3 tools:

- Shears for metal. They are good for cutting sheet steel. It is inconvenient to work with U-shaped profiles for gypsum sheets, but it is profitable. A manual version of a tool resembling nippers costs from 200 rubles. Also, the inconvenience of working with scissors smooth out their independence from the power supply and noiselessness.

- Electric jigsaw. Cuts neatly and quickly. It is convenient to work with the tool only with a rigid fixation of the profile. It is made of thin steel. If such a person “walks” under the jigsaw blade, the cut will be uneven.

- Miniature Bulgarian. In working with a grinder, the profile is laid on a bend. In other words, the cut-off part should hang over the air and bend under its own weight down as it is cut. The rest of the profile rests on a chair, table.

The convenience of handling a power tool is overshadowed by the noise emanating from it. However, you can wear headphones. Of the mandatory protective equipment, glasses are worth mentioning.

We cut the profile with a small grinder

Chips can fly off from the steel being machined. She can get into her eyes, damaging them. Such pieces of metal are called dross; they are extracted at emergency rooms.

The danger of cutting a profile with an electric tool is not only the damage to human health, but also the decoration of the apartment. Flakes of steel flies hot.

Stay away from wallpaper, plastic panels. Of course, they cannot ignite from the shavings, but point darkening-burns, sometimes remain.

Introducing the Toolbox

The mandatory list of DIY gypsum sawing tools includes three groups of items

1. Devices for applying marking on a GKL sheet - a simple pencil, tape measure, a long ruler.

2. Actually cutting and sawing devices.

- Knife.GVLV can be cut with a clerical knife, as well as with a specialized construction one with a double-sided replaceable blade (suitable for denser materials).

- Hacksaw. It is better if it is a tool for metal processing than wood.

- Jigsaw. Ideal for cutting rounded elements. Least of all, chips on the ends of drywall leave high-quality file for metal with a small tooth.

- Electric drill. Needed for making holes. For gaps of large d, round crowns (which cut the core of the door snap locks) and feather drills will be required.

3. Edging tools:

- peeling planer,

- chamfering planer.

This list clearly shows what home craftsmen cut drywall. Of course, he is far from complete. The arsenal of experienced craftsmen can include professional equipment, for example, a special milling cutter for GVL. However, for those who are working with the material for the first time, this kit is quite enough. To better understand how to cut drywall, you need to clearly understand the structure of this material.

Structure and purpose of drywall

Plasterboard sheets are a layer-by-layer combination of two types of materials - gypsum (internal content) and sheets of thick cardboard glued to it on both sides. It is clear that if the cardboard layers are damaged, it is not difficult to cut the rest.

Therefore, in order to be able to quickly cut a sheet of gypsum plaster, it is not enough to find out what is the best way to cut drywall. It is important to know the basic principle of this action: after continuous smooth cutting of drywall is carried out, the second step immediately follows - breaking the sheet.

Sawing drywall, like any solid porous material, is easy. It also lends itself well to drilling.

Functions of the material make it possible to differentiate it into varieties: moisture-proof, fire-resistant, standard, increased strength (for example, a gypsum board or a gyro-board made by KNAUF technology), acoustic drywall, etc.

Despite the large assortment of HA, panels of any of its varieties lend themselves well to dividing into parts by using available material.

Standard cutting

Cutting a sheet in a straight line is the easiest way to cut. It comes down to the following:

GVL is placed on a hard and even surface. Then mark the future cut line.

Whatever knife was chosen, they should be cut strictly by placing a ruler on the side. An uneven cut is guaranteed if it is decided to cope without a ruler. Cutting starts from the back (there is a denser cardboard layer). The front part of the Civil Code is somewhat different, as it is intended for finishing work. When cutting, they try to deepen the knife as much as possible into the gypsum contents.

At the end of the process, the HAs are turned over and bent in the direction of the entire (without cutting line) side. Gypsum, not touched by a knife, will be broken in the necessary direction. The cardboard on the opposite side is cut along the formed fold line.

Not particularly important is which side to start cutting drywall. However, on a flat, dense surface, this is much easier to do than when keeping the GL on weight.

Before you cut drywall with improvised devices, you should familiarize yourself with two more types of simple cutting, feasible for independent implementation.

Double sided cutting. More often in this way, cutting is performed in the shape of any rectangle. Using a hacksaw, they saw one side, the other - just cut with a blade. After which the material is cracked, and on the opposite side the cardboard is cut off (as with simple cutting). Finished trim is perfected using a planer for edging.

Rough line cutting. To cut the material along uneven lines, you must first prepare a drawing.

Cutting on the given geometry

Curved cutting of drywall is used in a situation of creating unique shapes for a specific structural element. This procedure is more complicated, and one cannot do without basic experience and a sufficient arsenal of tools.

In figured cutting, the material is also first marked out. If you need to draw a circle, but there is no compass at hand, then they are armed with a needle with a thread and a tied pencil.

For curly cutting of HA in different situations, one of the methods described below is applicable.

Option one. Describes the process when a hacksaw is selected as a tool. Manipulating a hacksaw is akin to working with a knife with cloves and a handle. Using a hacksaw from drywall, you can cut out fragments with any non-trivial forms (for example, butterflies or flowers).

Option Two. An electric drill with a cylindrical nozzle allows you to create flat circles of small diameter in drywall. The circle here is not marked, but limited to marking in the desired area.

Option Three. For sawing GVL with a jigsaw, a clear marking of the contour of the desired shape is performed. Priority in choosing a jigsaw is given when the diameter of the circle to be drawn must be larger than the diameter of the crown of the electric drill, and the rounded lines of the shapes are not limited to a circle.

The fourth option. The most primitive when choosing a tool comes down to a knife and a hammer. Drywall is cut along the intended boundary. At the same time, they try to press the blade as hard as possible.

After that, the HA is laid on a flat surface having a recess. Moreover, the detachable part of the element must fall into this hole. Leaning the sheet less efficiently on the wall. Then hit with a hammer in the middle of the detachable fragment. The removed part must break. A layer of cardboard is cut from the bottom, aligning the ends as needed. Masters in the Civil Code strongly recommend that people without experience resort to this technique. Since you have to spend a lot of drywall sheets for stuffing your hands and working out the pressure force.

The nuances of making circles

The circles in the ceiling structure are made primarily for the installation of lamps. The easiest way is to cut a circle of a given diameter with a blade in the gypsum fiber. And carefully knock out the middle part with a hammer. However, it will be easier to carry out the plan with a drill with special equipment - a cylindrical nozzle. The one that is used when inserting a lock mechanism with a latch into the door.

Cutting after installation of gypsum plasterboard

Of course, it is more convenient to cut material not yet fixed. But in practice, there are situations when it is required to cut off the excess after mounting the sheets to the frame. Such pruning is due to the fact that the sheathed surfaces meet window slopes or corners on their way.

The sheet is fixed to the wall, leaving a small margin of size. Excessive centimeters are already removed on the wall.

It is important to make sure that the ledger is securely fixed to the frame. An incision is made on the side that is in contact with the wall. Cutting movements are repeated repeatedly, by marking. At the same time, they try to squeeze out unnecessary parts of the material. The sheet is cut on the other side.

Having studied these methods, beginners will understand how to cut drywall in the presence of a minimum set of tools at home. If you need to cut HA in large quantities, these options will not work. The best solution is to turn to professionals.

Tool types

An affordable cutting method that most people use is scissors for metal. In addition to they use:

- hacksaw with small cloves for metal,

- a guillotine machine, a device for cutting a profile for drywall,

- jigsaw with a special file,

- a grinder with a cutting disc,

- small circular saw.

At large facilities where it is necessary to cut aluminum in large volumes, stationary machines of various types are used with saws and a milling cutter.

Scissors for metal

The advantage of the tool is that it is a simple and effective way of cutting. You can buy a household option or a professional one.

Scissors cut the strips both in size and at an angle of 45 degrees, make a radius or straight cut

Scissors cut the strips both in size and at an angle of 45 degrees, make a radius or straight cut

Things to consider when choosing a tool:

- Direction of cut, divided into right and left. They differ in the location of the lower blade. If the blade is on the left, then the scissors are for righties. Accordingly, on the right - more convenient for left-handed people. Direct working blade, without obvious displacement, is intended for linear horizontal cutting.

- The packaging indicates the maximum thickness of the metal that they can cut. For cutting the GKL profile, a tool for sheet steel, up to 0.8 mm, is suitable.

- It is better to choose a pruner from chrome-vanadium, chrome-nickel alloys, high-carbon steel. They will last a long time.

- The handle is chosen convenient. Rubberized with anti-slip coating and limiter, so that the hand does not slip.

Another mechanical tool

Hacksaw for metal is not used for permanent work. When trimming, the material must be fixed in a vice.

The guillotine machine is a professional tool. The profiles are cut quickly, the cut is smooth. The fixture is simple and effective.

It looks like a cutter for accurate and quick profile cutting

It looks like a cutter for accurate and quick profile cutting

Consists of the following elements:

- long lever handle (up to 80 cm), which is removable,

- high alloy steel blades,

- when lowering the guillotine, the blade enters the cutting mechanism,

- the metal profile is inserted into an adjustable clamp,

- the mechanism is mounted on a metal frame.

The machine well cuts guides and ceiling profiles, but is intended only for a straight cut. You cannot cut a metal bar at an angle.

Power tool

A metal disc mounted on a grinder or electric drill cuts the profile quickly and smoothly. The tool cuts straight and at an angle. Disadvantages:

- sparks fly during operation, you can damage the wallpaper,

- if a spark gets on flammable material, local fire is possible,

- the sound of the blade creates a noise effect.

A circular small saw will replace the grinder.

When working, observe safety precautions, wear safety glasses and gloves.

When working, observe safety precautions, wear safety glasses and gloves.

The best device is recognized as a jigsaw. It has stable fixation due to design features and a grip from above. The use of this tool is necessary if you need to cut a large number of profiles.

The end pendulum saw is a convenient, high-speed tool, but expensive. Suitable for professionals.

Useful Tips

To eliminate the unpleasant consequences of self-cutting drywall, it is recommended to follow the advice of professionals:

- When cutting and installing large-sized drywall alone, it is inconvenient to lift it and simultaneously adjust it with a hammer. It is recommended to put the bar on the floor and use it to break drywall exactly along the marked line.

- Most masters wonder which side to cut drywall with. The material is picky and breaks well both on the wrong side and on the front side.

- It is necessary to carry out the cutting of drywall immediately. In no case after installation, because it is possible to cut or break a soft product incorrectly.

- When working with circular cutting of drywall, it is possible to do without a compass. Plates, glasses or lids from pans will help to create a suitable circle.

- A grinder is not suitable for cutting drywall. The tool creates a cloud of dust that irritates the mucous membranes and makes noise. Also, the grinder requires additional protective equipment and skills to work with electric devices. It is safer to cut the GCR with a clerical knife and a hammer.

- To facilitate work with drywall can jigsaw, which has a rigid blade with small teeth. The tool is much better suited for creating decorative elements with an ornate configuration. For one time, experts recommend not renting, but renting the device from any construction company. It will be much cheaper.

In addition to recommendations for work, it is important to remember the fragility of the material. You cannot cut out a complex image with thin elements in drywall

The brittle structure collapses quickly even when cemented or primed. Drywall sheet will be durable only with large lines and when creating wide parts.

See how to properly cut drywall with your own hands in the next video.

Basic tools for cutting drywall

To cut drywall sheets to specific sizes, some simple tools are required, a list of which includes the following items:

Tools for cutting and processing drywall edges.

- Electric jigsaw. This tool can be convenient to make long cuts, and in particular it becomes necessary if you want to cut a complex curved shape. As a rule, our jigsaw is included in the instrumental "arsenal" of any private house, since it is difficult to manage without it in the household.

- A special knife for cutting drywall or a regular stationery knife with a removable blade. More information about this tool group will be provided below.

- A narrow hacksaw for wood with a small tooth set, or a special hand saw on drywall.

- An electric drill with a set of large pen drills, as well as crowns - for cutting large round holes for wiring communications, sockets for installing electrical outlets and switches.

- Drywall planer or regular wood planer. This tool will be necessary for processing edges when cutting material.

- A needle roller will be required if it is necessary to form an arched opening from a drywall or another curved surface, for example, for a complex multi-tiered ceiling structure.

- For measuring and marking sheets, you need a simple pencil or marker, tape measure, building angle, meter metal ruler. If there is no ruler, it can be replaced by a flat metal profile used to equip the frame crate. In addition, you must have at hand a construction rule for making long straight cuts “to the ruler”.

Drywall Cutting Knives

Due to the fact that the knife is the main tool for cutting drywall, its characteristics should be considered in more detail.

Nevertheless, the knife remains the main tool of the master when working with drywall

Drywall knives can be divided into three categories. Detailed information about them is presented in this table:

Knife Categories / Tool Features

| Standard knives | Such knives are the most affordable tool, and this is their main advantage. The design is quite simple, since it consists of four elements - a body-handle, a cover-retainer, a regulator-retainer of the blade and the replaceable blade itself. The reliability of such knives is quite low, especially when using them for cutting drywall. They are still more suitable for cutting paper. When cutting drywall, the blades quickly blunt. |

| Reinforced Knife Models | These are more expensive options compared to standard models. They differ from the first ones by the presence of a metal guide installed in the case, which more securely fixes the blade and provides rigidity of the position during the cut. |

| Professional knives | Such tools are used by craftsmen who constantly work with drywall. There are a lot of options for professional knives. They differ from each other in the ergonomics of the case, the principle of operation of the latch and some other design nuances. The price of such models is several times different from the ones mentioned above, and sometimes reaches 1000 rubles. |

In principle, drywall can be cut by any of these knife models. However, to decide on the choice of this tool, it is worth considering all the options in more detail.

It should be noted right away that knives with a blade of 9 mm should not even be considered, since they are not suitable for cutting drywall. Such a blade may not withstand pressure and break. Not only will this greatly slow down work - breaking a thin blade is often accompanied by a rather serious injury to the hand.

For cutting drywall, knives with a blade having a width of mm are used.

Appearance of the product Types of knives and cutters and their features

Now, having figured out what designs of knives are most often used for cutting drywall, you can decide on the choice of the main tool for work. This takes into account the scope of the material, the required shapes and sizes of the workpieces, the required level of accuracy. And, of course, the cost of the tool is compared with the scale of the tasks ahead, with the intensity of its use.

A few words about the structure of drywall

To begin with, a couple of minutes of attention should be paid to the structure of drywall, since this moment will immediately bring clarity to the process of cutting it. And the GKL “device” is very straightforward.

The structural structure of drywall.

The structural structure of the sheet of this material is a three-layer “sandwich”. The outer layers are made of dense cardboard, and the core of the pressed gypsum mixture. The lateral long sides of drywall usually have an edge with corners rounded or converging on the trapezoid and are also protected by cardboard. From the end sides, an edge is not provided.

Cardboard is produced in several types - this is ordinary (GKL) material of gray color, moisture-proof (GKLV) has green shades of the front side, fire-resistant (GKLO) is pink or light purple, and moisture-resistant (GKLVO) is a dark green shade. In addition, an innovative drywall designed for soundproofing walls has appeared on sale today. It is made in blue.

The most common standard sizes of sheets are 2500 × 1200 mm, that is, having an area of 3 m². Other options are available, but they are less common: 2000 × 1200 mm (2.4 m²) and 3000 × 1200 mm (3.6 m²). The thickness of the sheets can be 12.5 mm (for walls), as well as 9.5 mm and 6 mm, which are usually used to create ceiling structures.

The table below shows the main standard sizes of drywall with an indication of the approximate mass of the sheets. This is in order to be able to appreciate - the sheets are very bulky and quite heavy

That is, they should be handled carefully: they may not be able to withstand the fracture load during careless handling - they will break

Type of drywallSize of sheets (length × width × thickness), mmSheet area, m² Approximate sheet weight, kg

| GKL | 2000 × 1200 × 6 | 2,4 | 12 |

| 2000 × 1200 × 9,5 | 2,4 | 18 | |

| 2000 × 1200 × 12,5 | 2,4 | 23 | |

| 2500 × 1200 × 6 | 3,0 | 15 | |

| 2500 × 1200 × 9,5 | 3,0 | 23 | |

| 2500 × 1200 × 12,5 | 3,0 | 29 | |

| 3000 × 1200 × 6 | 3,6 | 18 | |

| 3000 × 1200 × 9,5 | 3,6 | 27 | |

| 3000 × 1200 × 12,5 | 3,6 | 35 | |

| GKLV | 2000 × 1200 × 12,5 | 2,4 | 24 |

| 2500 × 1200 × 12,5 | 3,0 | 30 | |

| 3000 × 1200 × 12,5 | 3,6 | 35 | |

| Hklo | 2000 × 1200 × 12,5 | 2,4 | 26 |

| 2500 × 1200 × 12,5 | 3,0 | 31 | |

| 3000 × 1200 × 12,5 | 3,6 | 37 | |

| GKLVO | 2000 × 1200 × 12,5 | 2,4 | 27 |

| 2500 × 1200 × 12,5 | 3,0 | 32 | |

| 3000 × 1200 × 12,5 | 3,6 | 38 |

However, no matter which drywall is used for construction or decoration, it is cut equally.

How to cut drywall?

And everything is ready. It remains only to deal with a small edge planer.

How to cut round holes

Almost always, these types of holes are used for cutout for a socket, chandeliers in the ceiling, lamps and other things. There are two options to accomplish this. The first is to take a special nozzle, with which holes are made for the lock in the door. Such a nozzle is mounted on a drill, and after that a hole is cut out.

With the second option you will not need a drill, but just a hammer and a cut circle of the right size. You need to attach this circle and gently hit with a hammer. Of course, the effect will be worse than with the nozzle, but it can also work well.

This type of cutout is usually used in toilets or in shower rooms, since there are a large number of pipes and other water supply nodes. The biggest problem is calculating the size of the cutouts. First, it is advisable to check the contour on which the cut will be applied several times.

If it is more than necessary, then there will be many problems with fixing the sheet to the frame. If it is not suitable enough in size, it will take your time to fit.

Next you need to make a plan of your actions. Take a look at your drawing a few more times. Usually in many cases, all the flaws in the curvature are a hybrid of straight lines and a semicircle. For straight lines and half circles, you have your own tools. In those areas where you are definitely planning to make a cut, use a hacksaw, and all uneven bends and roundness are cut thanks to the knife.

That's all, now you know how to cut drywall at home. There is really nothing complicated about this. Everyone knows that only with practice can experience come.

Drywall, one of the main building materials for interior decoration today

And in fact, with proper use, the material ensures the correct form, ease of installation, accessibility, cost-effectiveness, environmental friendliness, fire resistance, and also that ease of processing is not unimportant. Indeed sheets of drywall are easy to cut and cut at home

Anyone who has tried and knows how to do this, he will not doubt it. And if you went to our page to see for yourself this and learn how to easily cut drywall sheets, then we will help you with this.

The subtleties of the process

When cutting drywall, it is customary to observe some rules, such as:

- placing the sheet on a flat and stable surface,

- the surface should be dry and free of excess debris,

- use personal protective equipment for eyes and respiratory organs, since a large amount of small debris and dust remains during cutting.

A large sheet is recommended to be cut in stages.

When performing profile cutting, various types of tools are used:

- Hacksaw. This type of tool, regardless of whether it is narrow or wide, has a high flexibility of the cutting blade, which allows it to deviate from a given direction. This reduces the quality of work, and also increases the time spent on cutting.

- Bulgarian. The tool is one of the best in carrying out construction work, including when cutting drywall.

Also in our life, moments in which it is necessary to make an incision on an already installed sheet of drywall under a lamp, paintings or any other things are not excluded. There is also a method for this case.

First you need to make sure the drywall is securely fastened, after which the small holes we need are carefully cut with a jigsaw, a drill with a nozzle or an electric drill. Large holes are recommended to be cut with a knife according to the marking applied. Upon receipt of uneven edges, they can be removed with an emery cloth or a hacksaw.

When cutting circles, there are a number of nuances. The easiest way to cut a circle in drywall is to apply the required size to a sheet, then gently cut it in a circle with a blade and knock out the core with a hammer (with little effort with any similar object). There is also the simplest way, saving time and effort - using a drill with a special cylindrical nozzle. This type of nozzle is usually used when inserting a lock mechanism with a latch into the door.

There is also a so-called two-sided cut, which is carried out when various obstacles arise in the way of the sheet, whether it be doors, an aperture, a beam or any others. When such a situation arises, you have to make a cut (or cut) from the right side and the desired shape. This manipulation is quite simple, but requires focus, accuracy and attention. One side of the sheet must be sawed with a hacksaw, and the other side carefully cut with a knife. After completing the work, making a break and treating the edge with a planer.

When cutting drywall - it folds. It is advisable to do this carefully without damaging the sheet. There are three possible ways to drywall. The easiest way is to attach the desired workpiece to the profile and fix it in the right position with self-tapping screws. This method is used for small sheets measuring 20-30 centimeters and a small arc size.

A more complex and second method (for drywall) is to make cross-cuts in drywall. They are done on the outside of the arc. The incision depth usually should not exceed four to five millimeters of panel thickness.

We will also talk about folding a sheet for a door arch. The method has the unspoken name “wet”. First of all, the required dimensions of the arch are measured and applied to the sheet. Next, the sheet is cut, and non-through punctures are made on it using a needle roller. In the absence of a needle roller, the use of a conventional awl is allowed. Using a roller, sponge, rag or any other fabric, the punctured side is wetted with water so that the other side remains dry. After 15-20 minutes, the sheet of drywall is placed on the template with the wet side. Next, carefully give our panel an arc shape. The edges are fixed with screws or clamps. Leave for a day. After which the sheet can be used during installation.

We cut a sheet of drywall

Step 1. The gypsum board consists of two layers of paper, which on both sides cover a thick layer of gypsum. This combination creates a relatively strong building material, which is also fire resistant. Therefore, in order to obtain an accurate and high-quality cut, it is enough to walk along the plate with a sharp knife and then break it in this place. To make an incision, swipe the knife several times over the plasterboard from top to bottom. To make the correct cut, you need to lead with a knife confidently, without jerking and precisely along the marked line. Cutting through the paper layer, you need to firmly hold the tread band in one position, otherwise the cut may turn out to be uneven.

The same procedure must be performed if you are less likely to have drywall not on the floor, but leaning against the wall. While holding the trench down with your foot, swipe the knife over the drywall several times from top to bottom. There is no need to cut through many times, so you only blunt the blade of the knife.

Sheet with cut through paper base.

Sheet with cut through paper base.

As you can see in the picture, the cut should be completely even. Otherwise, you will not be able to break the slab evenly. The goal is to cut through the paper completely and grip the plaster lightly.

Step 2. Now you need to break the plate along the incision. If you followed the previous steps correctly, then the drywall sheet should break along the incision. Holding the sheet with your feet, just fold it.

Of course, there are a lot of options for how to make yourself a break. It is rather difficult to explain all these procedures with two sentences, but we assure you that in practice it is very easy to do. The most important thing is to make the right cut

How you will break it is not important.

But if you find it difficult to grab a large sheet with your hands to bend it, then press it with your knee. If you are not sure that you can cut a slab well, then practice on waste sheets first.

Breaking a plasterboard.

Breaking a plasterboard.

Step 3. After the sheet is broken with a clerical knife, cut the paper layer on the back of the drywall. If you correctly broke the drywall, then you should not have problems with cutting a layer of paper from the back.

Cut the layer of cardboard on the outside.

Cut the layer of cardboard on the outside.

Step 4. Attach the cut-off plate to the attachment point to see how accurate the cut was. If the cut-off plate turned out a little more, then use the rasp to remove excess material. Remember that when working with a rasp, you will make a lot of dust. Therefore, try to make precise markings.

How to cut drywall with a knife without a table: video

Drywall installation work involves cutting sheets into parts of the right size. At home, the master does not often face such a task, so buying professional electric saws for cutting HA is inexpedient. When working with large volumes of HA, cutting speed comes to first place, therefore, for a master who is engaged in installation constantly, the acquisition of such equipment is relevant.

A set of tools for working with the Civil Code

But in order to make a box for the ceiling or an arched opening in your home, the work of cutting the ledger can be done with the usual general-purpose tool available in the arsenal of any home master. And in order to understand how to cut drywall correctly, you first need to figure out what kind of material.

In order to bend and cut drywall without problems at home, either in a straight line or in a complex line, you must first understand the structure of this material. Its name fully speaks of it: in fact it is a sandwich, the core of which consists of a fragile mixture based on gypsum, which is glued with cardboard on both sides. When preparing parts, the properties of drywall are used, due to its material and structure:

The core gives hardness to drywall, and cardboard prevents it from breaking. If the cardboard layer is damaged, the HA easily breaks in this place. Performing a continuous straight cut of the cardboard and then breaking the sheet is the main principle of quick cutting.

- Like any solid porous material, HA is easy to drill and saw. Plaster is cut with any hand tool.

- The porous mass of the filler is able to absorb moisture, while the material reversibly loses its hardness and lends itself to deformation. After giving the required shape, the HA dries and regains strength. This property is used to obtain solid arched parts with uniform bending.

How to make drywall holes

Next, we will talk about how to make a hole in drywall. Learning to make holes in drywall is very important, since it often needs to be done to install new outlets, switches and other devices. In addition, round or rectangular holes have to be cut in order to repair damaged plasterboard sections. Although cutting holes in drywall is quite simple, nevertheless, in order to do it professionally, you need to use certain tools and have some skills. Therefore, we advise you to work with caution and follow our step-by-step explanation exactly before you get started.

To make a hole in drywall, you need the following:

- Tire Tire

- pencil,

- tape measure and stationery knife,

- drill,

- ring nozzle for a drill,

- jigsaw

- hacksaw for drywall.

- make accurate measurements for making rectangular holes,

- be careful not to damage pipes or electrical wires when cutting holes

- wear a respiratory mask to cut a hole in the drywall.

Cut a rectangular hole

#1. Determine the place on the drywall sheet where you need to make a hole. If it is supposed to install a socket in this hole, then in the necessary place you need to attach the box from the socket and outline its outline. To do this, use a tape measure to measure the distance from the left side of the plate to the left and right edges of the box. Also measure the distance from the bottom edge of the cooker to the extreme top and bottom points of the electrical box. Given these dimensions, use a trowel to mark the location of the box hole on the drywall.

# 2 Drill with a large diameter drill to make 4 holes on the sides of the rectangle. As you can see in the picture, the holes must be made inside the rectangle and as close as possible to the cut lines.

Clever advice.You can drill holes not on the sides, but in the corners of the rectangle. The holes must be large enough for the jigsaw blade to pass there.

# 3 Insert a jigsaw file into each of the holes to cut a rectangular opening. Do this with great care, making sure that the file goes exactly along the drawn lines.

Clever advice. Wear a respiratory mask to avoid breathing dust. It is better to make the hole a little small than a big one, since the excess can always be removed with a rasp.

#4. After you cut a hole in the drywall, you need to check its suitability. To do this, insert a box from the switch or outlet into the hole made to see if everything is well done.

Clever advice. You can cut holes in already installed slabs, but there are a few things to consider. Before doing work, make sure that there are no pipes, wires or other communications in this place.

How to make round holes in drywall

#1. First you need to determine how you can cut a hole in drywall. There are several ways to do this. For this, you can, for example, use a crown, ballerina or a small hacksaw.

We advise you to use a crown, which is mounted in an electric drill chuck. It should be said that this is the fastest and most accurate method. It can be used to cut through small and medium holes.

Before you start making holes, you need to make the appropriate marking. To do this, you need to identify and outline the center of the future hole.

# 2 Select the crown of the required size and fix it in the drill chuck. Now place the core drill in the center of the cut hole and start drilling. For a quality hole, we recommend cutting at medium speed and smoothly pressing the drill.

Clever advice. Do not press too hard on the drill so that the nozzle does not get stuck in the cast. To make a hole of high quality, you need to be patient.

We make holes with a hand tool

Method 1 Cut a round hole in drywall with a conventional knife. First you need to outline the shape of the future hole. To do this, you can attach a box from a wall outlet, a switch or any other round object to a sheet of drywall and outline the contour of the future hole. Then the same outline should be noted on the back of the sheet. And the first and second circuits must match.

Then with a knife you need to completely cut through the cardboard layer. After you cut the paper layer on both sides, lightly tap the gypsum with a hammer. The hole is ready. Now check if the electrical box is included.

Method 2 If you want to make a hole in an already installed drywall plate, then you need to use a different method. Draw a circle on the drywall by drawing a pencil around the circuit breaker box or outlet. Before cutting a hole in drywall, make sure that there are no pipes or electrical wires in this area. Also make sure the box is in a suitable place.

Then, using a drywall saw, cut a hole in the plate. In order to make the hole smooth, break drywall in one place and, starting from there, start sawing.

Subscribe tochannelto get more useful information! And do not forget to like.